13

The tests are carried out at the frequency of operations corresponding to the class of intermittent duty.

Following the tests of mechanical endurance, the cont actor shall still be capable of complying with the operating

conditions. There shall be no loosening of the parts used for connecting the conductors.

(4) Electrical endurance

With respect to its resistance to electrical wear, the contactor is characterized by the number of on-load operating

cycles, corresponding to the service conditions given in Table 10 which can be made without repair or replacement.

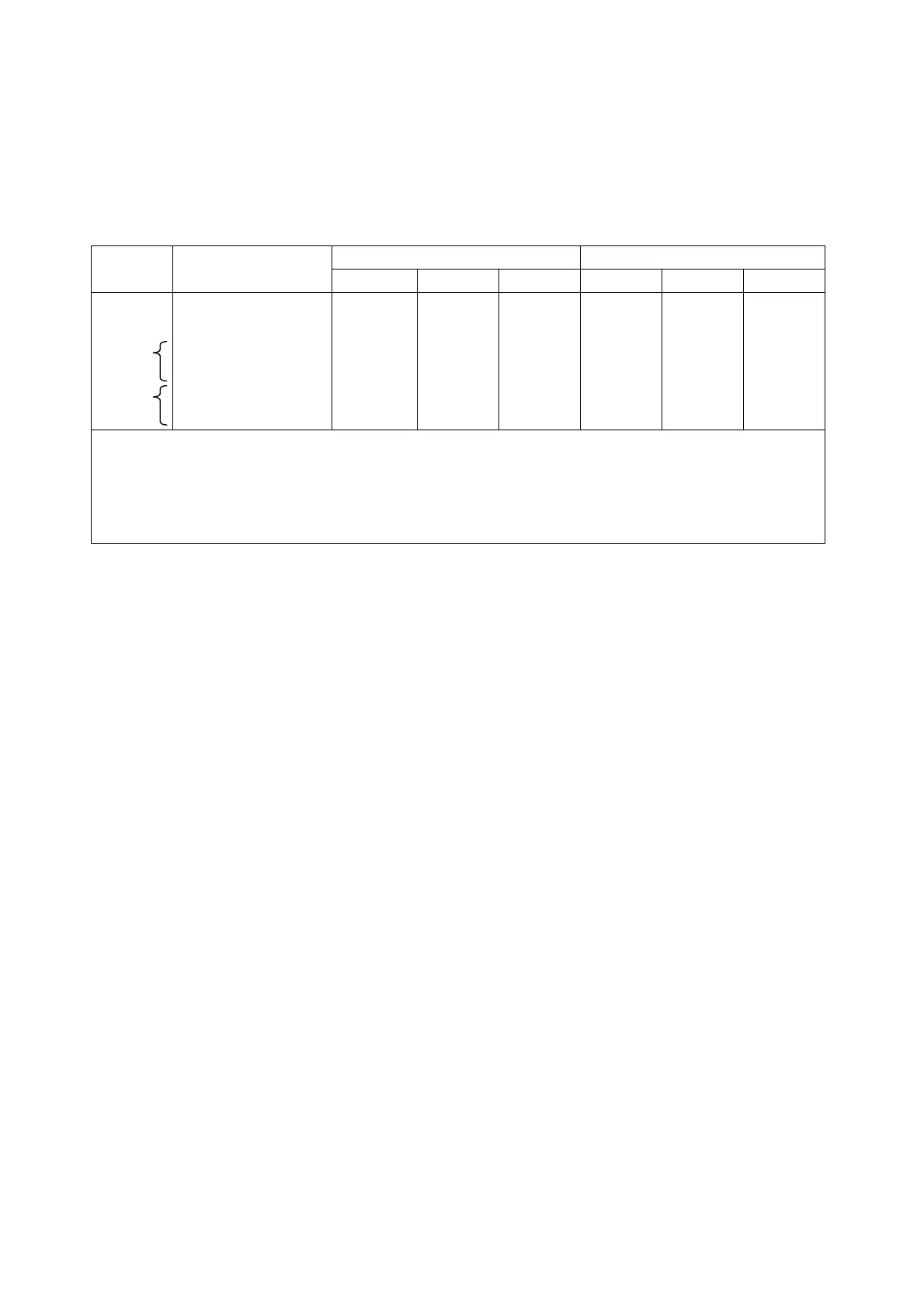

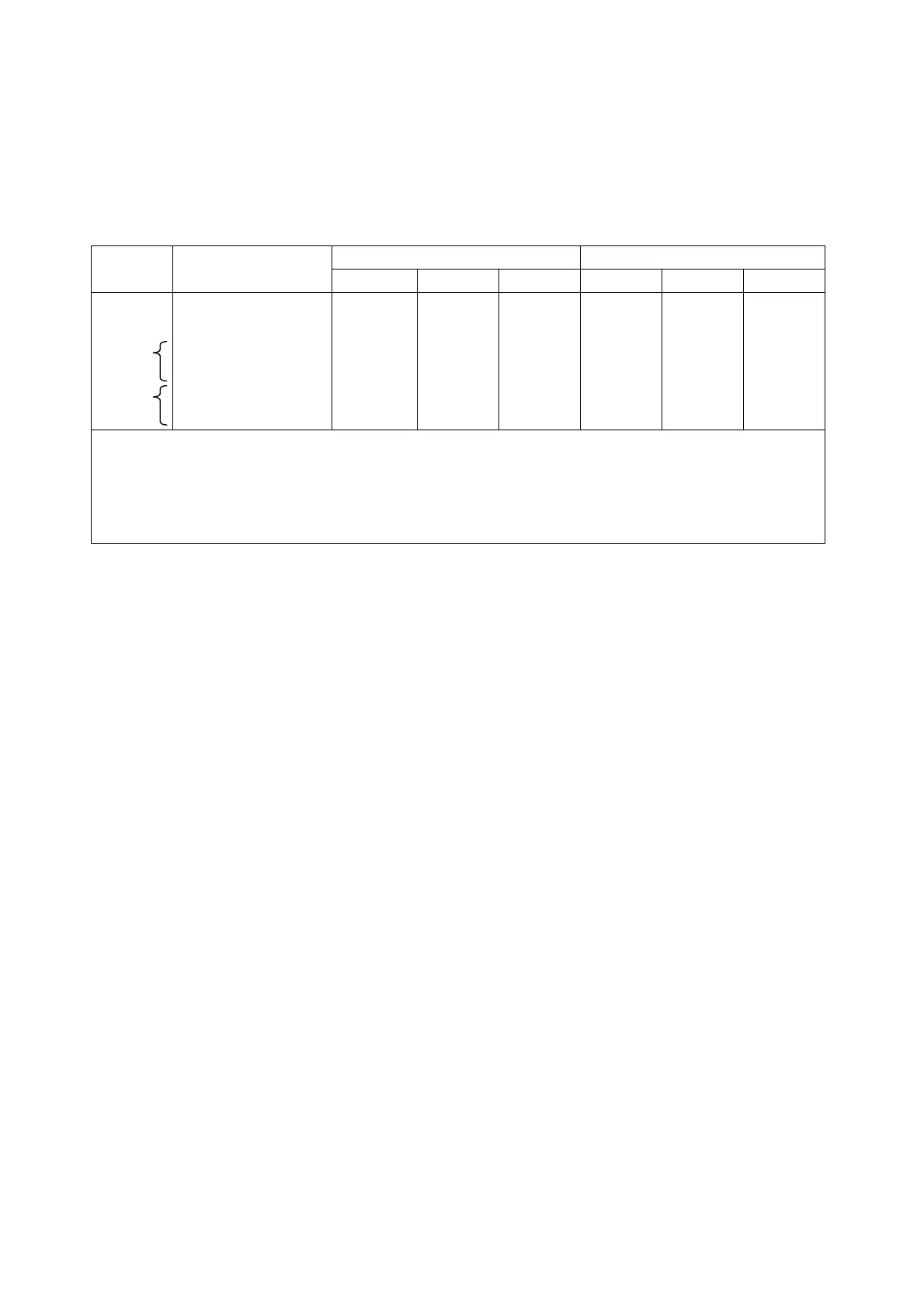

Table 10. Conditions for making and breaking corresponding to several utilization categories (IEC 60947-4-1)

Make Break Category Value of the rated

operational current

I/Ie U/Ue cosφ(1) Ic/Ie Ur/Ue cosφ(1)

AC-1

AC-2

AC-3

AC-4

(All values)

(All values)

Ie ≦ 17A

Ie > 17A

Ie ≦ 17A

Ie > 17A

1

2.5

6

6

6

6

1

1

1

1

1

1

0.95

0.65

0.65

0.35

0.65

0.35

1

2.5

1

1

6

6

1

1

0.17

0.17

1

1

0.95

0.65

0.65

0.35

0.65

0.35

Ie ; Rated operational current U ; Voltage before make

Ue ; Rated operational voltage Ur ; Recovery voltage

I ; Current made Ic ; Current broken

1) Tolerance for cosφ: ±0.05

After the test, the contactor shall fulfill the operating conditions and withstand the dielectric test voltages.

2-3 CHARACTERISTICS

2-3-1 Voltage Allowable Range of Coil

When the power-source voltage of the operating circuit temporarily varies within a range of -15% to +10% of the

rated voltage of coil, the contactor operates without any trouble. However, when the voltage constantly becomes

higher or lower than the rated voltage, the following failures may occur, so be sure to use the contactor at the rated

voltage .

(1) Where the power source voltage is higher than the rated voltage

(a) As the coil becomes overheated, its life may be shortened and it may be burnt. The electrical loss of the operating

coil increases in proportion to approximately the square of the applied voltage, while the temperature rise of the

coil is approximately in proportion to the electrical loss. Accordingly, if the power source voltage is 110% of the

rated voltage of coil, the temperature of coil rises approximately 20%. As a result, there is a possibility that the

life of the coil may be shortened and the coil may be burnt.

(b) The shock on closing becomes great and the mechanical endurance is shortened, or the contact jumps; as a result,

there is a possibility of increased contact wear and occurrence of welding. The higher the voltage applied to coil,

the greater the attraction. When the voltage increases by 10%, the attraction increases by about 20%. Because of

this excessively strong attraction,

Loading...

Loading...