14

(i) the iron core of the electromagnet is damaged by a strong shock, and the fatigue of molded parts and pressed

parts becomes greater, with the result that the mechanical endurance of t he contactor is shor tened by

approximately 50%.

(ii) the contact increasingly jumps due to the strong shock and there is a possibility of abnormal wear and

contact welding due to making and breaking of starting current of the motor.

(2) Where the power source voltage is lower than the rated voltage

When the power source voltage is low, it nears the closing voltage (lower than 85% of the rated voltage) of the con-

tactor. As a result, a case occurs wherein the electromagnet is not attracted to the fullest extent because of variation

of voltage, voltage drop due to rush current of coil, and the like, so that the contact flutters and troubles may be

caused including abnormal contact wear and contact welding, or burning of coil (because the rush current of coil

flows for a long time).

Moreover, the motor may incur failures such as burning caused by continuous flow of starting current.

The starting current of the motor causes voltage drop if the wire of the main circuit is long or fine, so the voltage of

coil becomes lower than 85% of the rated voltage, and the same phenomenon as above may take place ; attention

should be paid to this point. The causes of voltage drop of power source at closing are shown in Table 11 , so that

they should be investigated and measures against them taken.

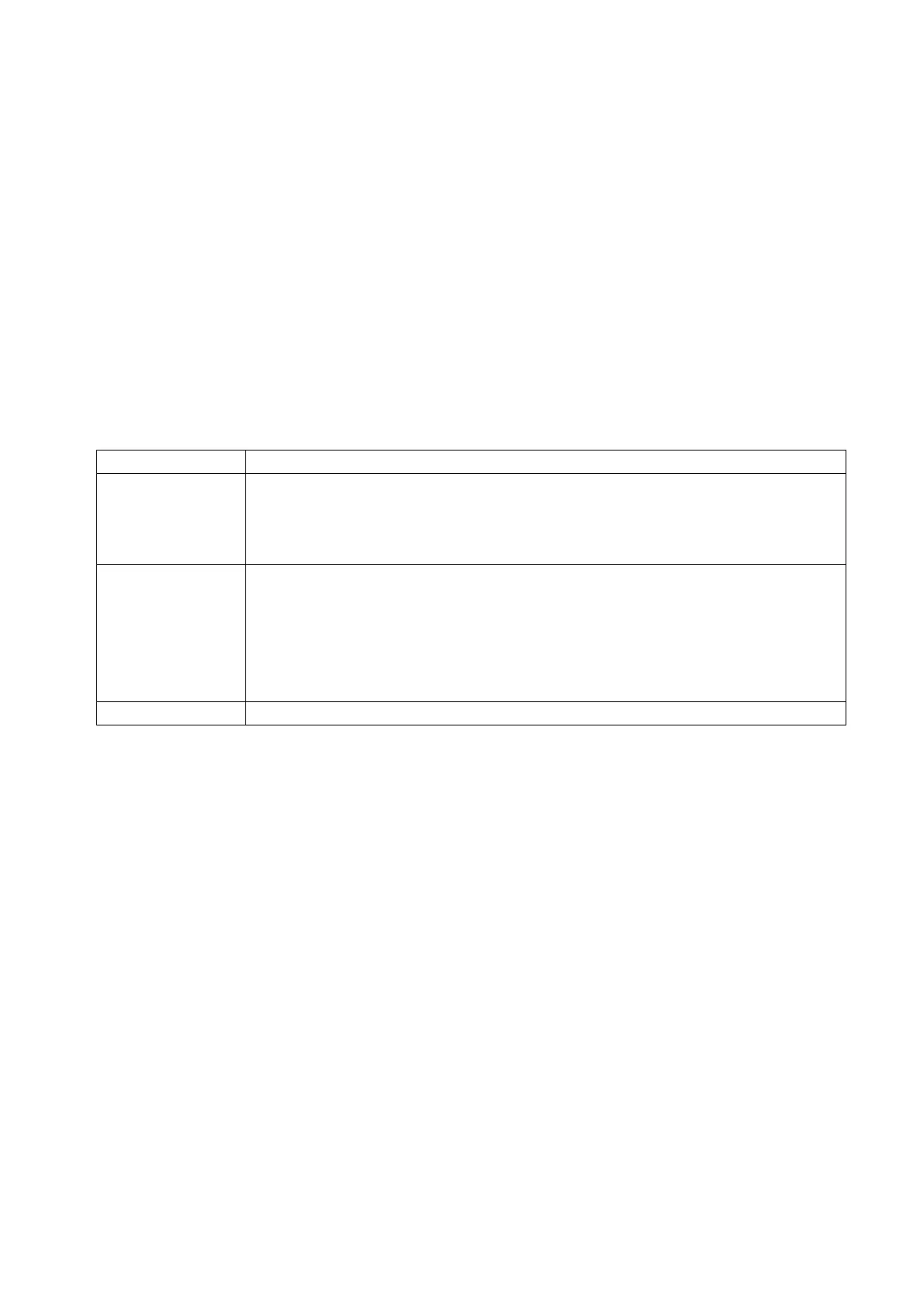

Table 11. Causes of voltage drop of coil power source

Class Causes

Main circuit ・ The wire of main circuit is fine, so the voltage is dropped by the starting current

of the motor.

・ The wire of main circuit is long, so the voltage is dropped by the starting current

of the motor.

Operating circuit ・ The wire of operating circuit is fine, so the voltage is dropped by the rush current

of the coil.

・ The wire of operating circuit is long, so the voltage is dropped by the rush current

of the coil.

・ The capacity of power source transformer for operating circuit is short, so the

voltage is dropped by the rush current of the coil.

Power source ・ The voltage regulation of power source is large.

2-3-2 Operating Time

Cited below are the items to which attention should be paid when handling the closing and releasing times of the

contactor.

(1) Closing and releasing time

The closing and releasing times of the contactor vary from 10 to 50 ms as shown in the catalog. This is due to the

phase and value of voltage applied to the coil and the friction of the mechanical section. Examples of these variations

are as shown in Fig. 14.

Where it is not desired that two electrical signals are sequentially lapped, the contactor is placed in the other circuit

to create a time lag. However, this time lag is not a strict time difference, but one which is used as appropriate when

an approximate time lag is wanted.

While, if this closing or releasing time is used in place of a timer to get the accurate time lag, no degree of accuracy

can be expected because of the above-mentioned variation from 10 to 50 ms. Attention, therefore, should be paid

to this point.

Loading...

Loading...