8 REFRIGERANT PIPING & REFRIGERANT CHARGE

8.1 PIPING MATERIALS

1 Prepare locally-supplied copper pipes.

2 Select the piping size with the correct thickness and correct

3 Select clean copper pipes. Make sure there is no dust and

moisture inside. Blow the inside of the pipes with oxygen

free nitrogen to remove any dust and foreign materials

before connecting pipes.

? NOTE

• A system with nomoistureoroilcontaminationwill give maximum

performance and lifecycle compared to that of a poorly prepared

system.Takeparticularcaretoensureallcopperpipingiscleanand

dryinternally.

• Thereisnorefrigerantinthecycleoftheindoorunit.

! CAUTION

• Allexternalpipingshallbeselectedinsizeanddimensionavoiding

anymechanicalstrengthduetocontractionorexpansion,vibrationor

refrigerantpulsation.

• Allthepipingshallbeprotectedagainstanyenvironmentaleffectlike

waterfreezing,corrosion,etc.Whenexiblepipeisused,precautions

shallbetakenagainstmechanicaldamages,excessivestressesby

torsionoranyother.

• Flarenutconnectionsshallbeaccessibleformaintenancepurposes.

• Ensurethatrefrigerantpipingisearthedpriortounitsinterconnection

andincaseofadditionalrefrigerantchargingisrequired.

• Captheendofthepipewhenpipeistobeinsertedthroughahole.

• Donotputpipesonthegrounddirectlywithoutacaporvinyltapeat

theendofthepipe.

• Ifpipinginstallationisnotcompleteduntilnextdayoroveralonger

period of time, braze off the ends of the piping and charge with

oxygenfreenitrogenthroughaSchradervalvetypeaccessttingto

preventmoistureandparticlecontamination.

• Do not use insulation material that contains NH

3

because it can

damagecooperpipematerialandcanbeasourceoffutureleakage.

• Completely insulate both refrigerant gas piping and liquid piping

betweentheindoorunit(s)andtheoutdoorunit.

• Ifnotinsulated,dewwilloccuronthepipingsurface.

After connecting the refrigerant piping, seal the refrigerant

Insulate the liquid piping and gas piping completely to avoid

decreasing of performance and dewing on the surface of the

pipe.

8.2 PIPING CONNECTION FOR OUTDOOR UNIT

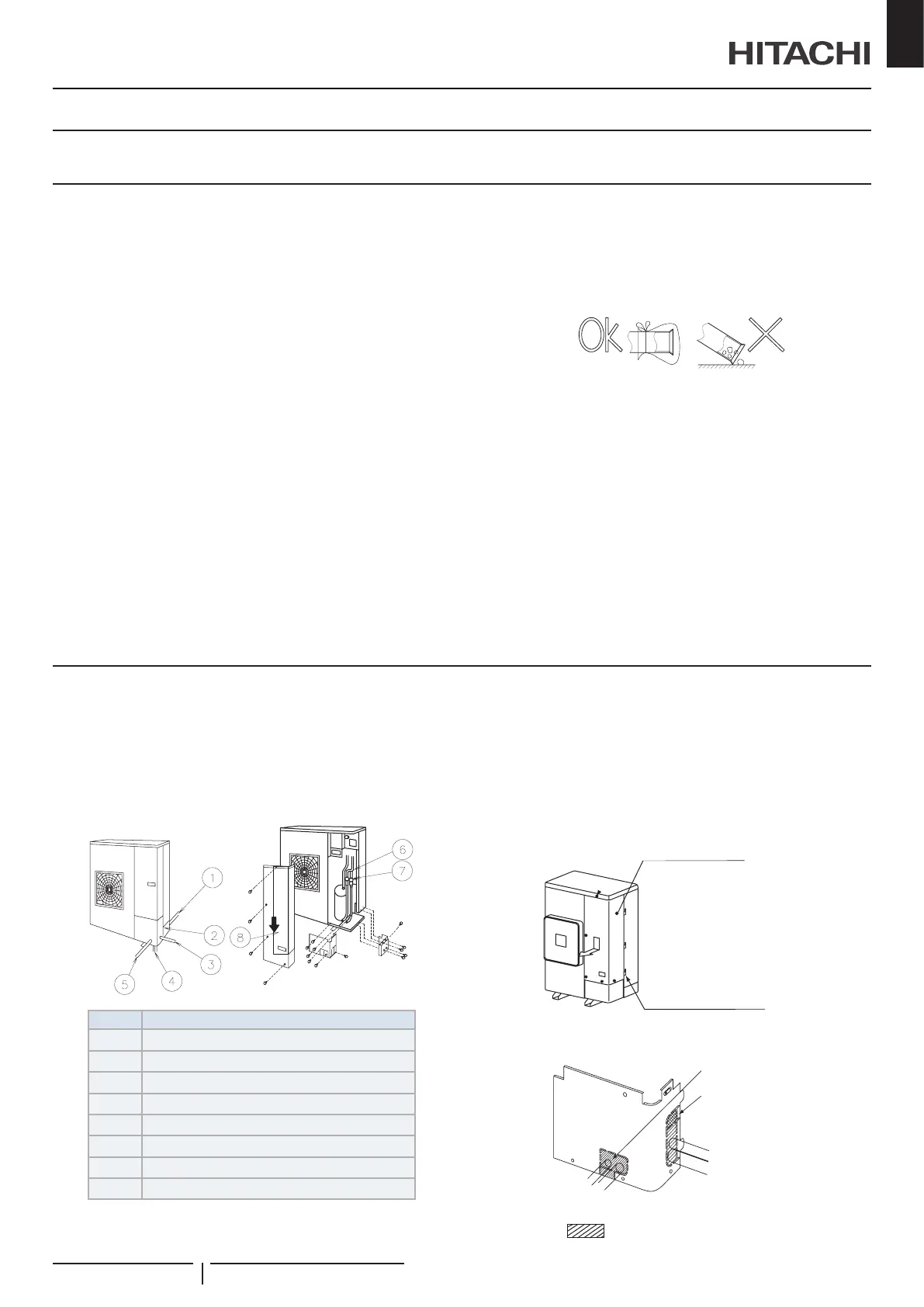

1 The pipes can be connected from 4 directions. Make holes

in the piping cover or cabinet for taking out pipes. Take the

piping cover away from the unit, and make holes by cutting

along the guideline at the rear of the cover or punching

with a driver. Remove the burr with a cutter, and place a

Nº Description

Rear side piping work

Pipe Cover

Right side piping work

Bottom side piping work (Knock out hole)

Front side piping work

Piping work

Stop Valve

Removing Direction for Service Cover

(pictureasexample)

! CAUTION

Notestoopen/closetheservicecover:

• Removethescrewsfollowingtheinstructionstotheabovegure.

• Slowlypressdownthecover.

? NOTE

Holdthecoverwithahandtoremovescrewsasthecovermayfalldown.

Service cover

Clasp (3 places)

(pictureasexample)

a. For the front and side piping

Front piping hole

Side piping hole

To use racking or conduit tubes, check the size and

remove part following the slit.

Refrigerant piping & refrigerant charge

PMML0545 rev.2 - 04/2021

9

EN

Loading...

Loading...