English

20

(3) Remove the deflection guard when bending a rebar whose bending length and the

fixed length are more than 20" (inside dimension of the deflection guard).

CAUTION:

䡬 Set a rebar on the rebar cutter/bender so that the bending length is equal to or shorter

than the fixed length.

6. Bending by eye measurement.

Since the unit uses a variable-speed switch, you can bend the rebar to your desired angle

by eye measurement in addition to the dial setting.

(1) Set the setting dial to a larger angle than you

desire.

(2) Pull the switch trigger lightly and bend the rebar

slowly.

(3) When the rebar is bent to the desired angle,

stop pulling the switch. If the bar is still small of

the desired angle, pull the switch again.

(4) Remove the rebar after bending has been

finished. Then, pull the switch once more and

return the bending roller to the home position.

(Continue pulling the switch until the bending

roller begins reverse rotation.)

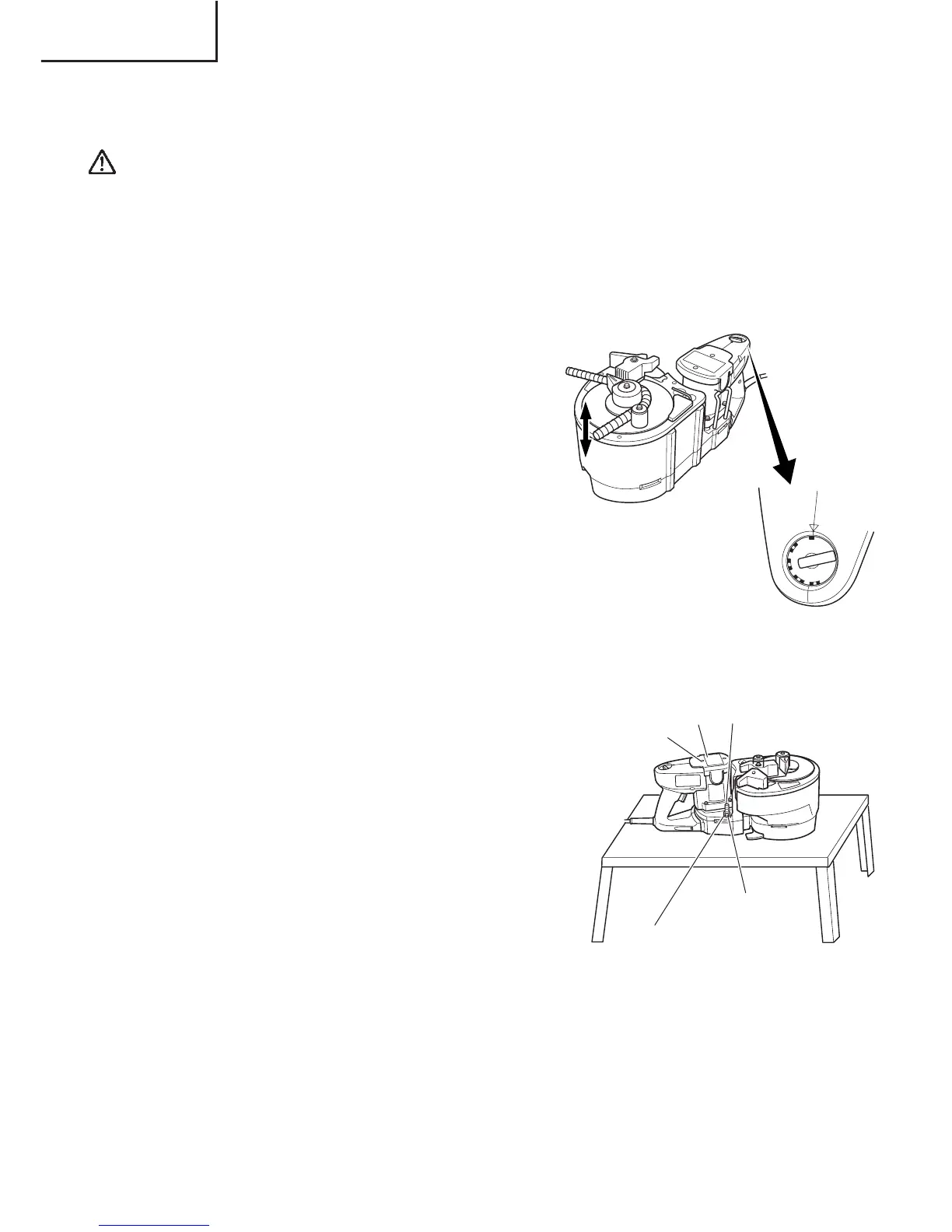

7. Removing rebar during bending operation

When bending out at a low speed in “bending by

eye measurement”, the rebar can sometimes get

caught in the bending roller due to its own flexure.

If this occurs, you can return the bending roller to

the home position by pulling the switch again after

setting the setting dial to the “return” position.

This is the same method used to remove the rebar

when it gets caught during cutting operation. (Fig.

21)

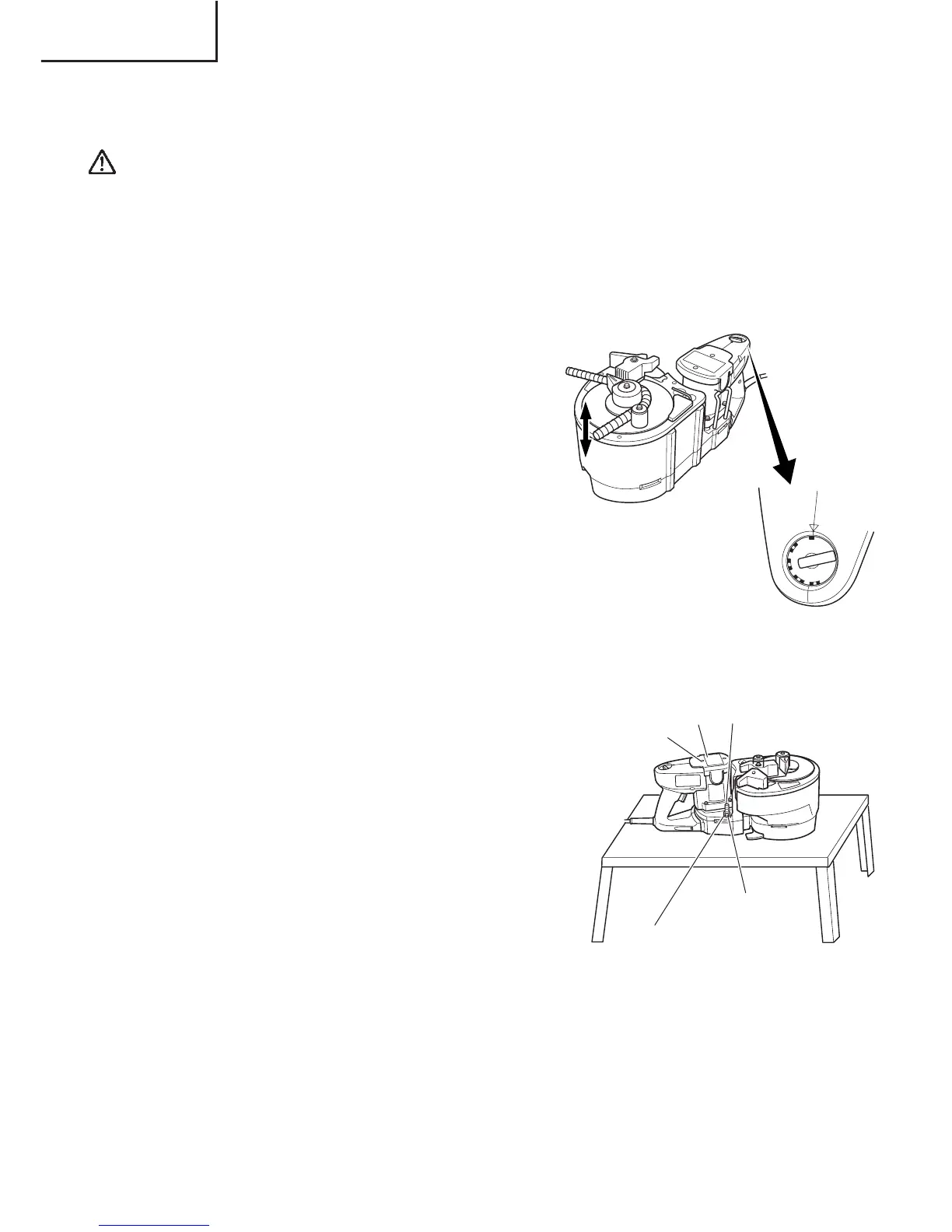

8. Using hole to fix unit in place.

A hole is provided at the center of the unit to fix and

stabilize it. This hole comes in quite handy when

used in the following manner. (Fig. 22)

䡬 For bending operation when the unit is fixed to

a work bench.

This hole will prove very convenient when the

unit is bolted to a suitable work bench.

(Bolt size M10, less than W3/8.)

Fig. 21

Fig. 22

Bolt

Tail

cover

Set

screws

Nut

Hole to fix

unit

Loading...

Loading...