Operations Manual

HKS 700E

31

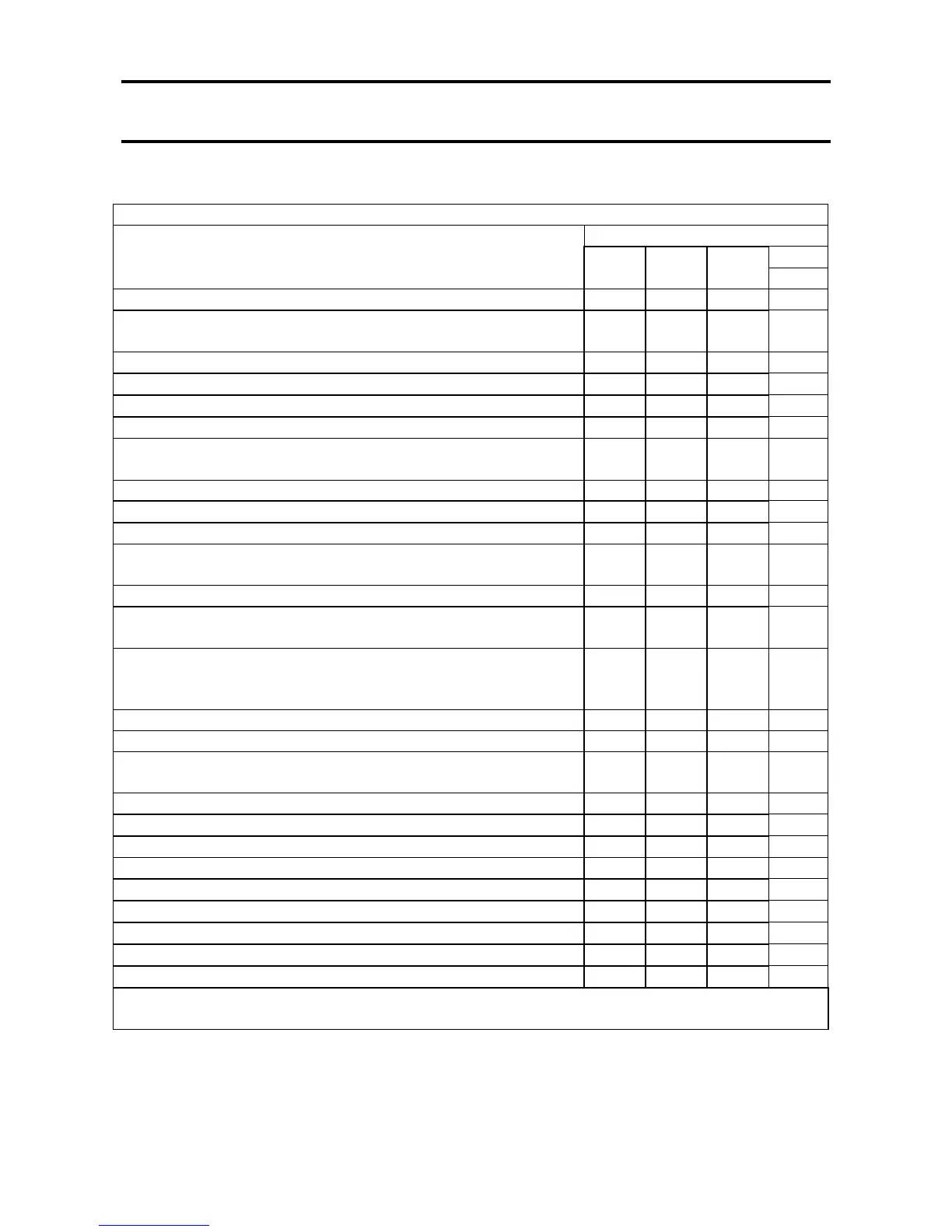

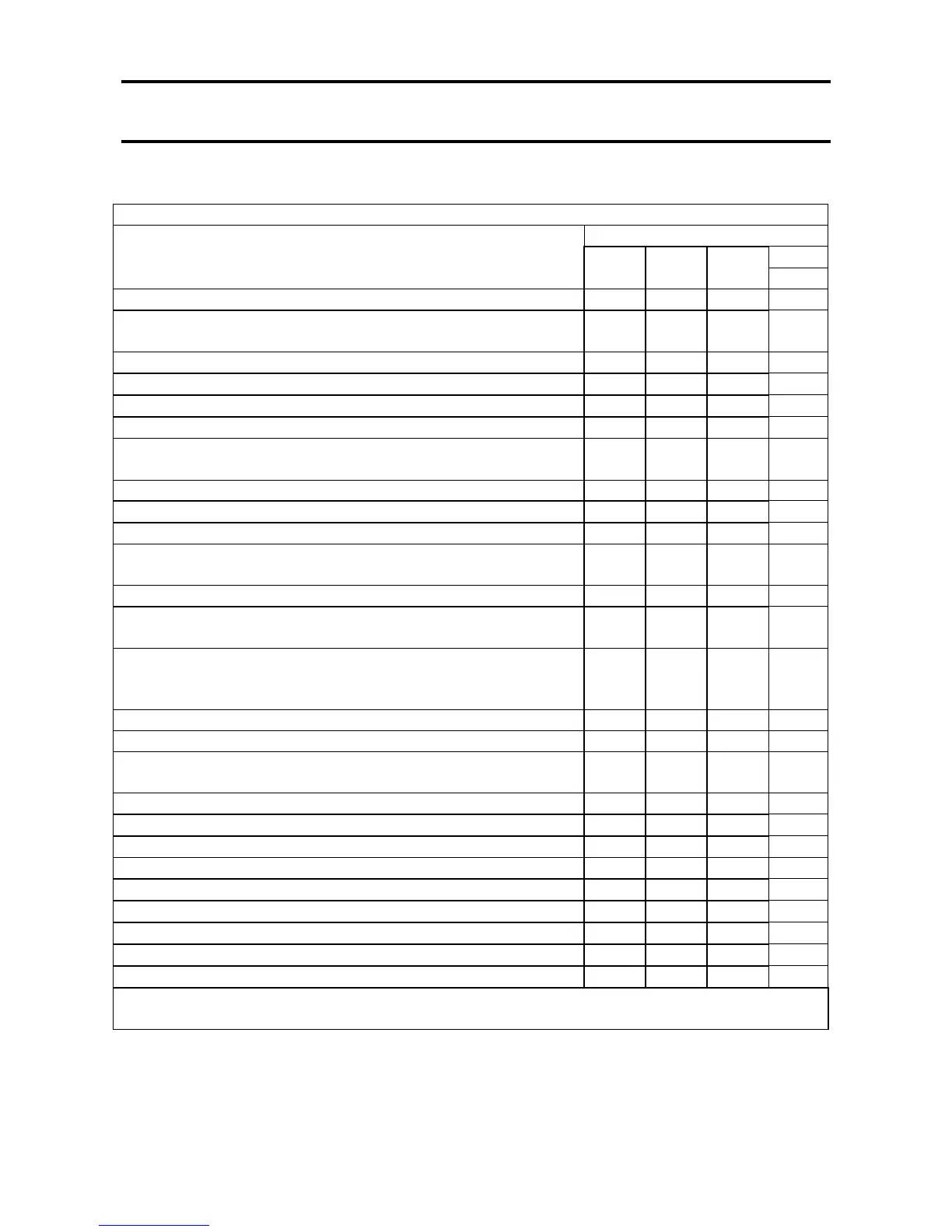

11. INSPECTION AND MAINTENANCE ITEMS

HKS-700E Inspection and maintenance program

Inspection-maintenance item. Hourly inspection routine

First Every Every Every

25hr. 50hr. 100hr. 200hr.

1. Check condition of throttle cable, starting carb. O O O O

2. Engine mounts-check for cracks, looseness of mounts,

and looseness of engine to mount.

O O O O

3. Check for looseness of bolts, nuts and pins. O O O O

4. Check for oil leaks from hose, tank and fittings. O O O O

5. Exchange oil filter. O O O O

6. Perform oil change. O O O O

7. Check the magnet of oil drain screw for the metal

contamination.

O O O O

8. Fuel lines-check for leaks, safeties and wear. O O O O

9. Fuel filter-check, clean or replace. O O O O

10. Clean the float chamber of the carburetors. O O O O

11. Check ignition harness for damage and tight

connections at spark plug cap.

O O O O

12. Air filter-check, clean or replace. O O O O

13. Check mounting of carburetors, and the insulator

rubber for cracks.

O O O O

14. General condition of the exhaust system, Check muffler

and attaching flanges at exhaust port on cylinder for

leakage.

O O O O

15. Check ignition coils for wear and security of attachment. O O O O

16. Check for leaks at oil pressure and temperature sensor. O O O O

17. Electrical wiring-check for damage, wear and security

of attachment.

O O O O

18. Check resistance of electrical equipment. O O O O

19. Check crankcase for leaks and cracks. O O O O

20. Clean engine if dirty or oily. O O O O

21. Compression checks (See operation manual). O O

22. Check spark plug caps. Change if necessary. O

23. Change spark plugs. O

24. Change the fuel filter. O

25. Change the air filter. O

100-hr-inspections must be performed at least annually. The overhaul must be performed

within 8 years after shipping or 1000hours operation time.

Loading...

Loading...