OM−221 534 Page 7

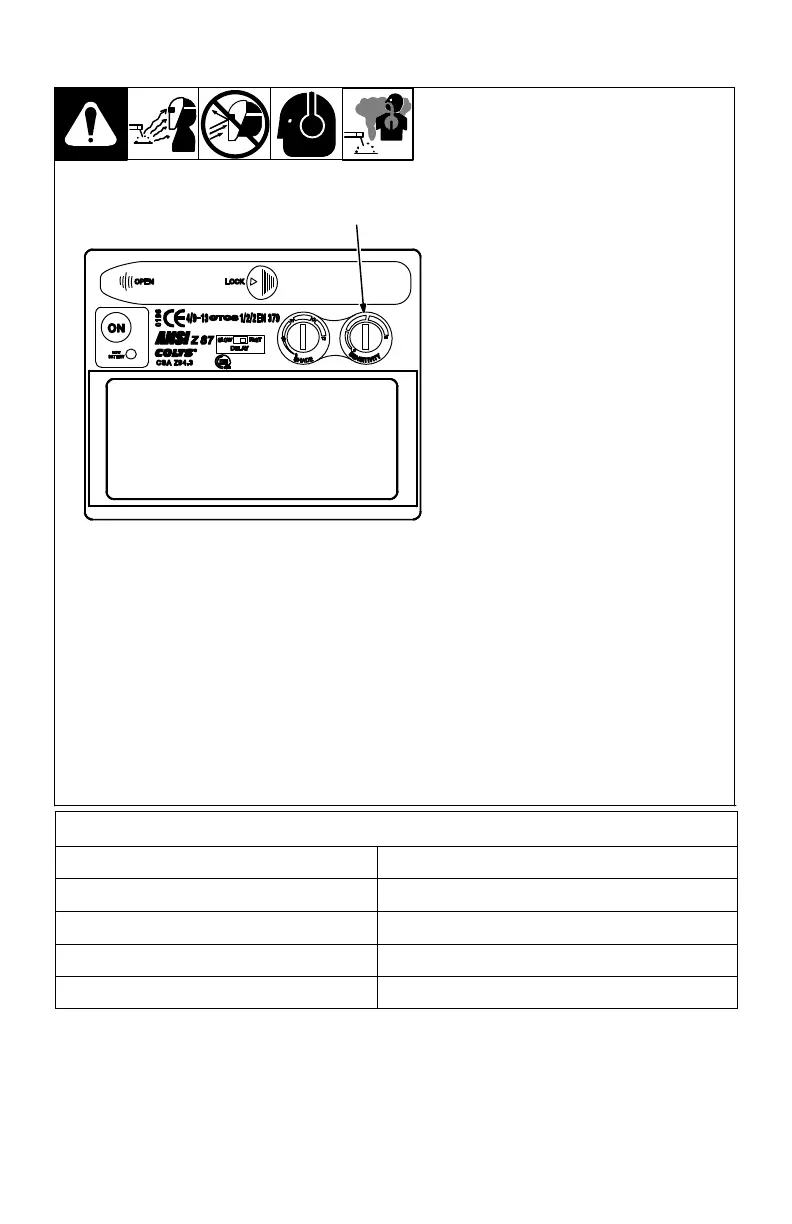

3-6. Sensitivity Control − XVS Model

1

1 Sensitivity Control

Use control to make the lens more

responsive to different light levels in

various welding processes. Use a

Mid-Range or 30−50% sensitivity

setting for most applications.

It may be necessary to adjust helmet

sensitivity to accommodate different

lighting conditions or if lens is flash-

ing on and off. Adjust helmet sensi-

tivity as follows:

Adjust helmet sensitivity in light-

ing conditions helmet will be

used in.

Turn sensitivity control to lowest

setting.

Press On button to turn helmet

On. Helmet lens will darken

twice and then clear.

Face the helmet in the direction

of use, exposing it to the sur-

rounding light conditions.

Gradually turn sensitivity setting

clockwise until the lens dark-

ens, then turn sensitivity control

counterclockwise until slightly

past setting where lens clears.

Helmet is ready for use. Slight

readjustment may be neces-

sary for certain applications or if

lens is flashing on and off.

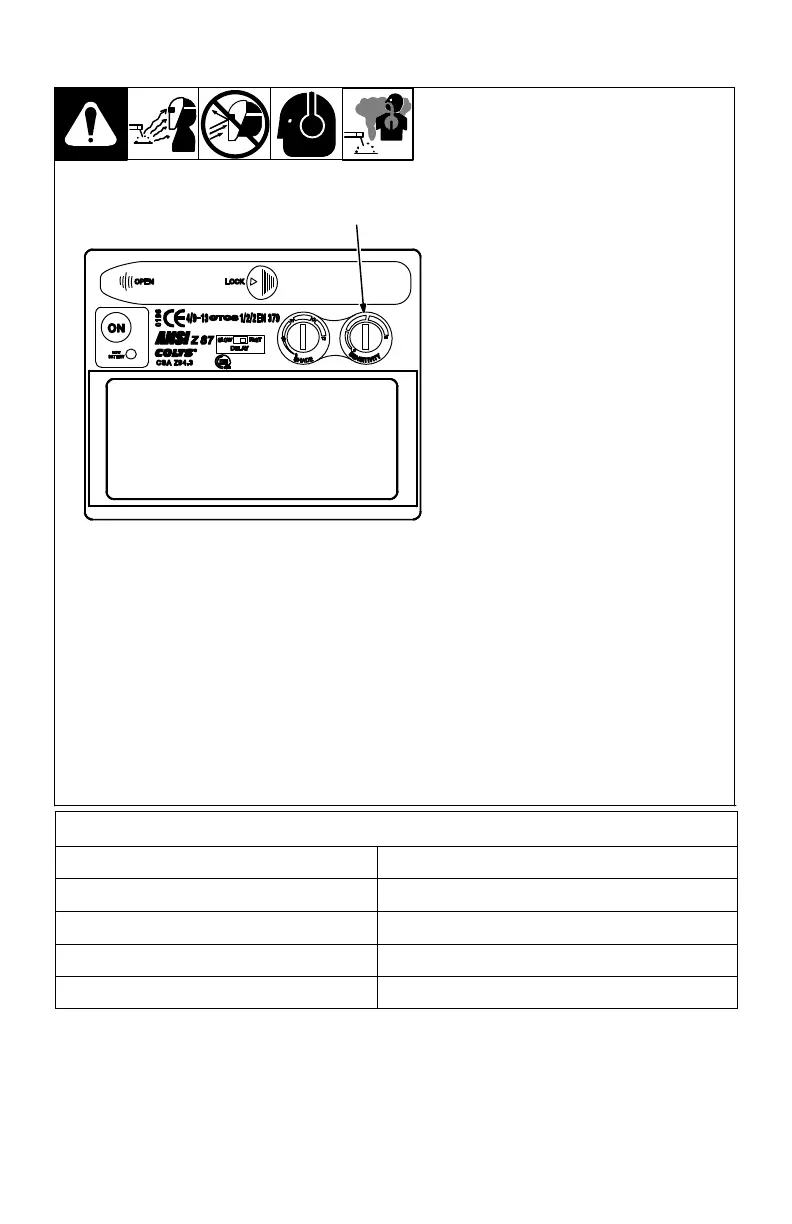

Recommended Sensitivity Settings

Stick Electrode Mid-Range

Short Circuiting (MIG) Low/Mid-Range

Pulsed & Spray (MIG) Mid-Range

Gas Tungsten Arc (TIG) Mid/High-Range

Plasma Arc Cutting/Welding Low/Mid-Range

Loading...

Loading...