©/TM

2023 UnityLab Corp. All rights reserved. | 109

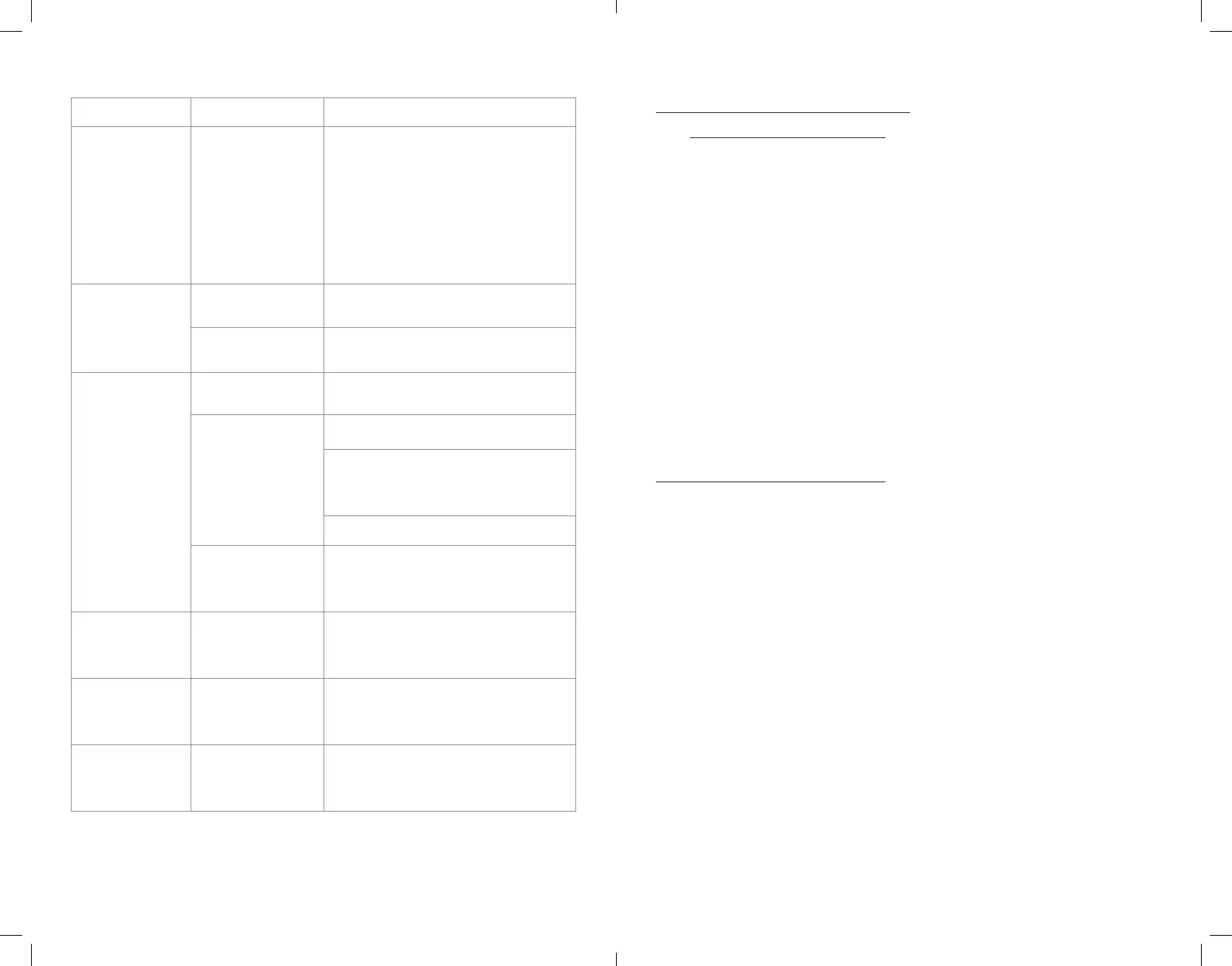

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Water is dark

brown or black.

Rust in Water.

See Section 4.3 – Blowing Down the

Boiler. Rust is a normal occurrence

in steam generator shells. The rust

appearance in the water will slowly

disappear after a few weeks of use. The

steam generator must be blown down

in accordance with instructions given in

this manual. Blowing down will minimize

the visual amount of discolored water.

No steam

comes from the

Solenoid Valve.

Bad Foot Switch.

Check Switch. See Section 5.7 –

Replacing the Electric Foot Switch.

Bad Solenoid Valve.

Replace. See Section 5.10 – Replacing

the Electric Solenoid Valve.

Can not ll with

water.

Breather valve not

open.

See Section 3.0 – Operation.

Check Valve is

stuck.

Lightly tap valve.

Clean valve seat. Disconnect power

and remove pressure from the boiler.

Check no pressure by leaving the

breather open.

Replace valve.

Water Inlet

Solenoid Valve fails

to operate.

Replace Water Inlet solenoid Valve.

Boiler keeps

lling.

Inlet solenoid Valve

is dirty.

Clean seat in Solenoid Valve. WARNING:

Disconnect Power before servicing.

Drain Boiler.

Wet Steam.

Too much water in

Boiler.

Drain tank until water level lls sight

glass approximately 75%.

Hard to see

through the

Sight Glass.

Minerals have

coated the glass.

Clean or replace. See Section 4.2 –

Cleaning the Sight Glass or Section 5.4

– Replacing the Gauge Sight Glass.

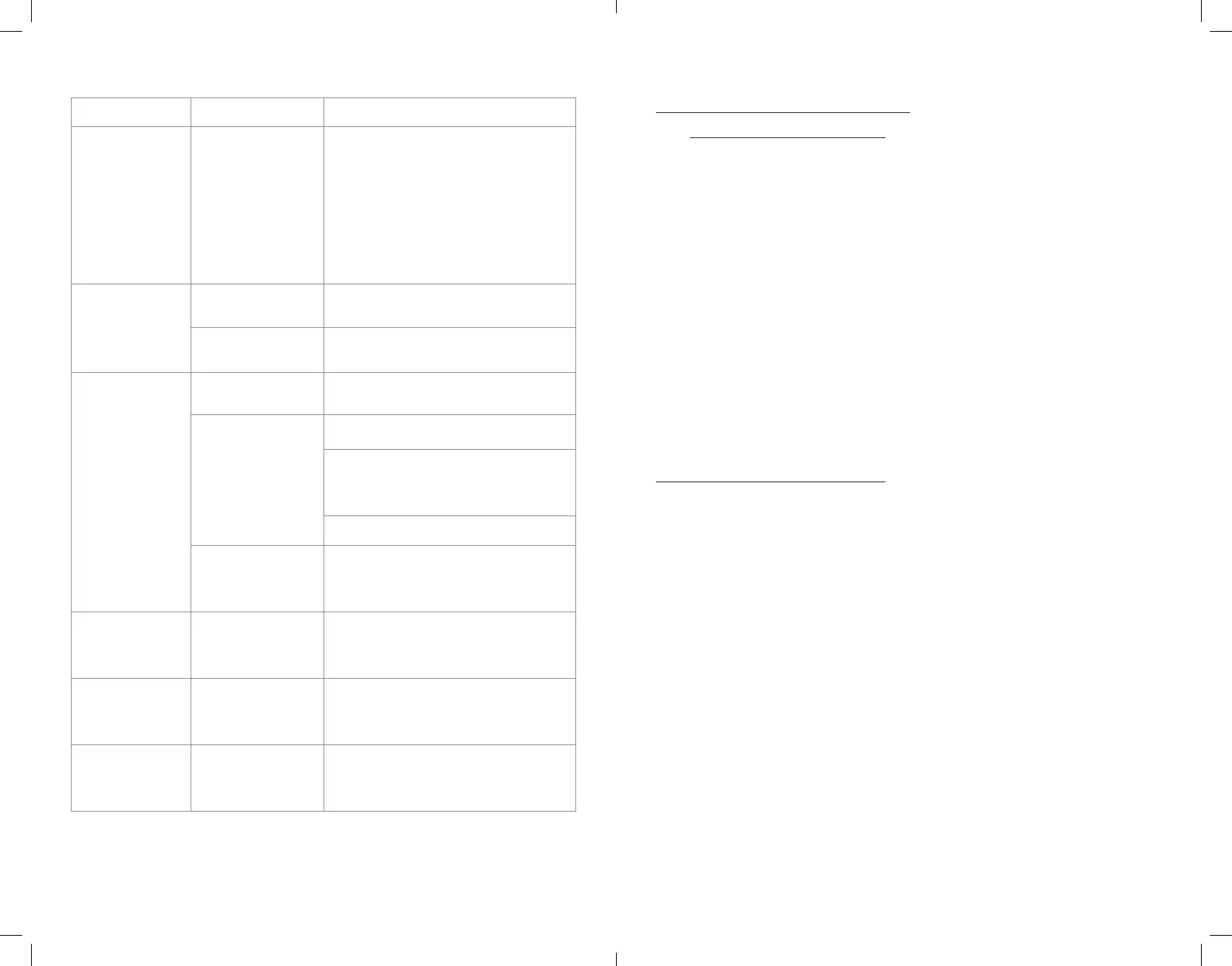

5.2 ADJUSTING THE STEAM PRESSURE

5.2.1 THERMOSTAT CONTROL

1. Power the boiler.

2. Turn the thermostat to “10.”

3. Allow the boiler to come up to pressure.

4. Remove the dial from the thermostat.

5. Using a small screwdriver, turn the screw inside the stem clockwise to

reduce the pressure, counter clockwise to increase the pressure.

6. Turn the stem in ¼ turn (90 deg.) increments. Allow the unit to heat or

cool. The nal high pressure is reached when the heating light goes out.

7. Use a dab of nail polish to secure the screw in position.

8. Put the dial back on the thermostat.

9. The maximum pressure setting shall be 90 psig. Attempting to raise

pressure higher will result in relief valve venting.

10. All eld wired units are supplied with a knock-out sized to UL

specications. Inside the electrical panel is a wiring schematic for

power and ground connections.

5.3 REPLACING THE THERMOSTAT

(To be performed by a licensed electrician)

1. Turn the power to the boiler off by pulling the plug or turning off the power at

the branch switch or circuit breaker.

2. Remove the wires on the thermostat.

3. Remove the dial from the thermostat.

4. Remove the mounting screws that hold the thermostat to the enclosure.

5. Remove the temperature sensing probe from the heating element.

6. Mount the new thermostat to the enclosure.

7. Insert the temperature sensing probe into the heating element. The sensing

probe may not go in all the way. This is normal. Insure that the sensing

tube is bent slightly up and out of the way of the heating element electric

connections. Do not kink the capillary tube.

8. Rewire the thermostat.

9. Power the steam generator. Adjustment may be necessary. If the pressure

comes too close to the safety valve rating (within 10 psig) turn the unit off

and adjust the thermostat in accordance with instructions given in this

manual.

Loading...

Loading...