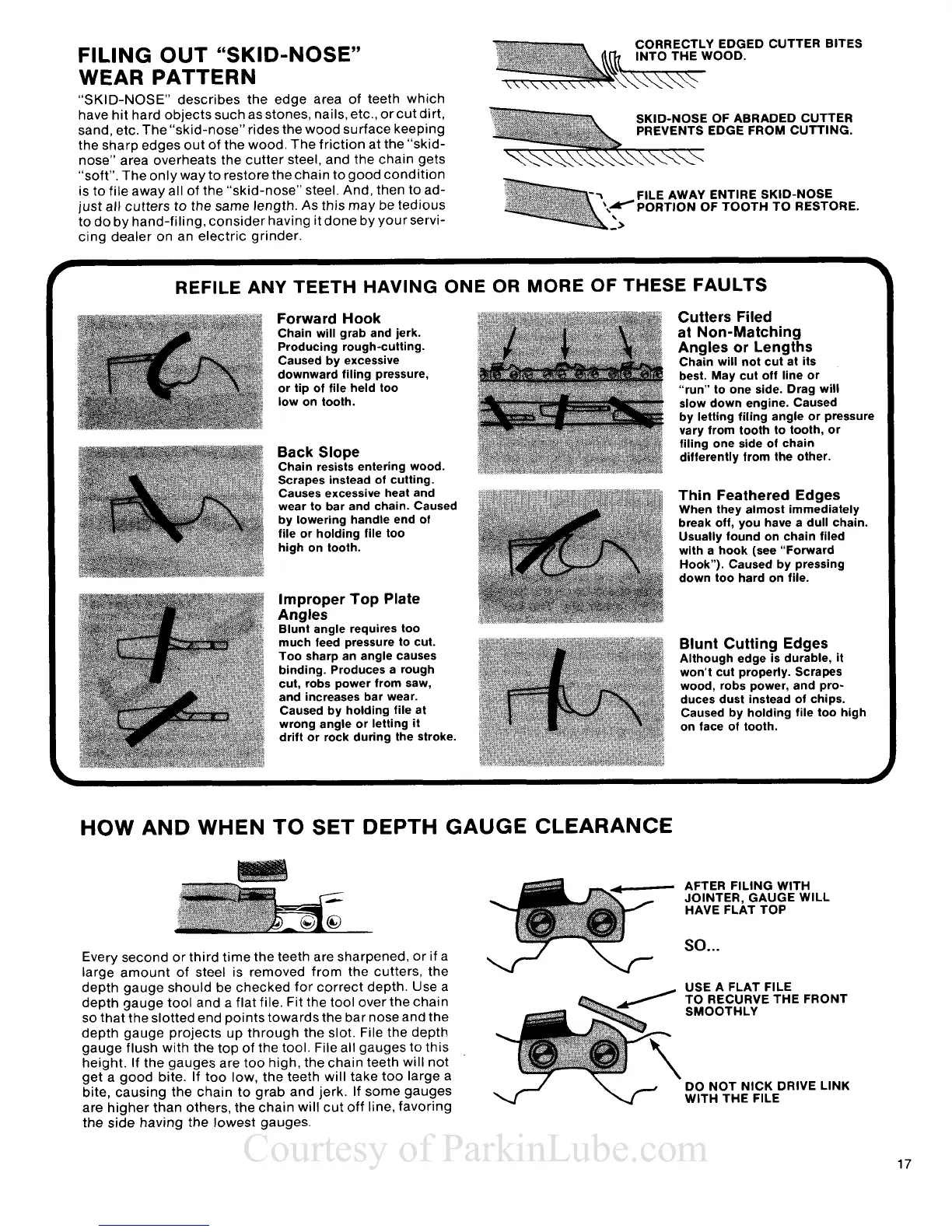

FILING OUT "SKID-NOSE"

WEAR PATTERN

EDGED CUTTER BITES

OOD.

"SKID-NOSE" describes the edge area of teeth which

have hit hard objects such asstones, nails, etc., or cut dirt,

SKID-NOSE OF ABRADED CUTTER

sand, etc. The "skid-nose" rides the wood surface keeping

PREVENTS EDGE FROM CUTTING.

the sharp edges out of the wood. The friction at the "skid-

nose" area overheats the cutter steel, and the chain gets

"soft". The only way to restore the chain to good condition

is to file away all of the "skid-nose" steel. And, then

toad-

FILE AWAY ENTIRE SKID-NOSE

just all cutters to the same length. As this may be tedious

F TOOTH TO RESTORE.

to do by hand-filing, consider having it done by your servi-

cing dealer on an electric grinder.

REFILE ANY TEETH HAVING ONE OR MORE OF THESE FAULTS

1

Forward Hook

Chain will grab and jerk.

Producing rough-cutting.

Caused by excessive

downward filing pressure,

or tip of file held too

low on tooth.

Back Slope

Chain resists entering wood.

Scrapes instead of cutting.

Causes excessive heat and

wear to bar and chain. Caused

by lowering handle end of

file or holding file too

high on tooth.

Improper Top Plate

Angles

Blunt angle requires too

much feed pressure to cut.

Too sharp an angle causes

binding. Produces a rough

cut, robs power from saw,

and increases bar wear.

Caused by holding file at

wrong angle or letting it

drift or rock during the stroke.

Cutters Filed

at Non-Matching

Angles or Lengths

Chain will not cut at its

best. May cut off line or

"run" to one side. Drag will

slow down engine. Caused

by letting filing angle or pressure

vary from tooth to tooth, or

filing one side of chain

differently from the other.

Thin Feathered Edges

When they almost immediately

break off, you have a dull chain.

Usually found on chain filed

with a hook (see "Forward

Hook"). Caused by pressing

down too hard on file.

Blunt Cutting Edges

Although edge is durable, it

won't cut properly. Scrapes

wood, robs power, and pro-

duces dust instead of chips.

Caused by holding file too high

on face of tooth.

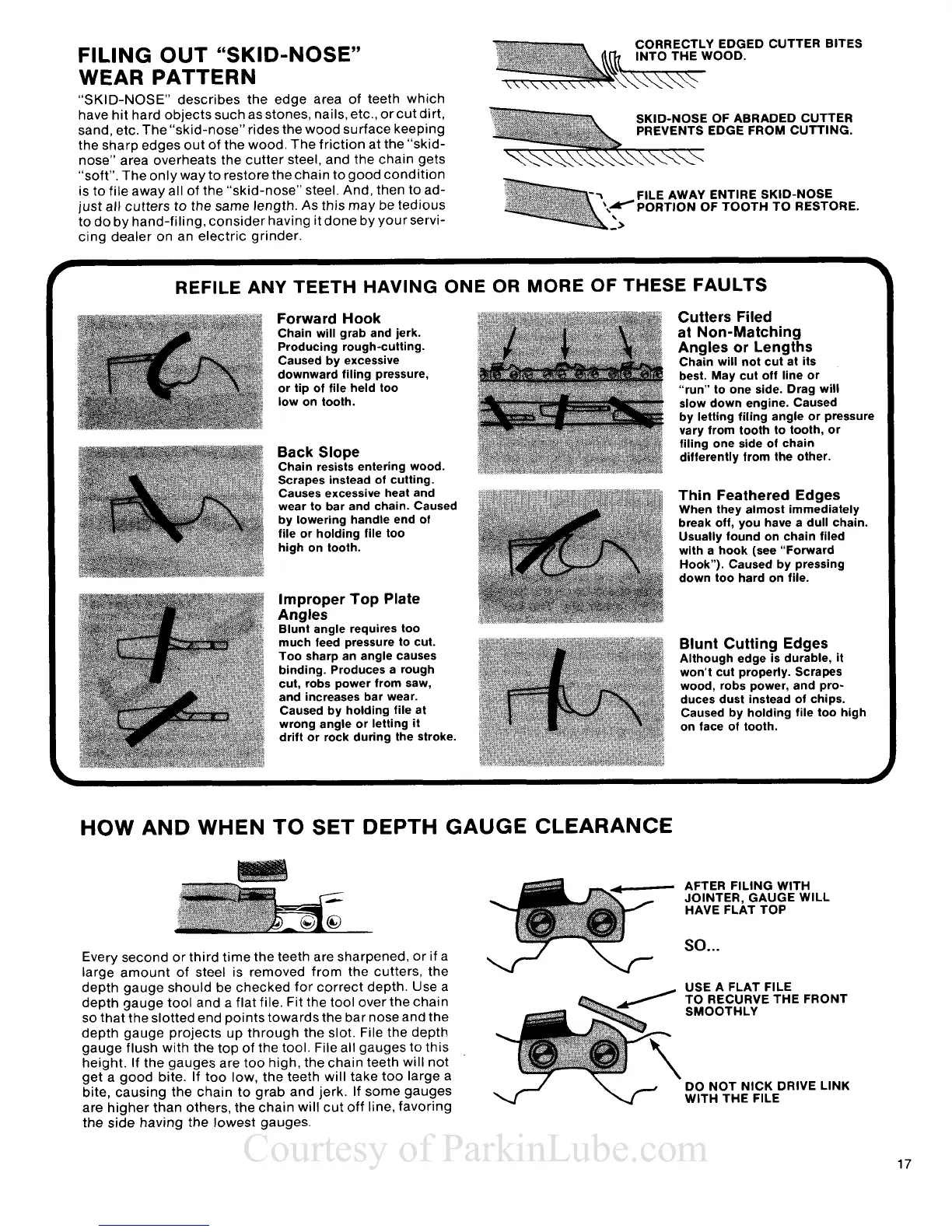

HOW AND WHEN TO SET DEPTH GAUGE CLEARANCE

AFTER FILING WlTH

JOINTER, GAUGE WILL

HAVE FLAT TOP

SO

...

Every second or third time the teeth are sharpened, or if a

large amount of steel is removed from the cutters, the

depth gauge should be checked for correct depth. Use a

USE A FLAT FILE

depth gauge tool and a flat file. Fit the tool over the chain

TO RECURVE THE FRONT

so that the slotted end points towards the bar nose and the

SMOOTHLY

depth gauge pr0jec.t~ up through the slot. File the depth

gauge flush with the top of the tool. File all gauges to this

height. If the gauges are too high, the chain teeth will not

get a good bite. If too low, the teeth will take too large a

bite, causing the chain to grab and jerk. If some gauges

DO NOT NICK DRIVE LINK

are higher than others, the chain will cut off line, favoring

WlTH THE FlLE

the side having the lowest gauges.

Loading...

Loading...