T TO

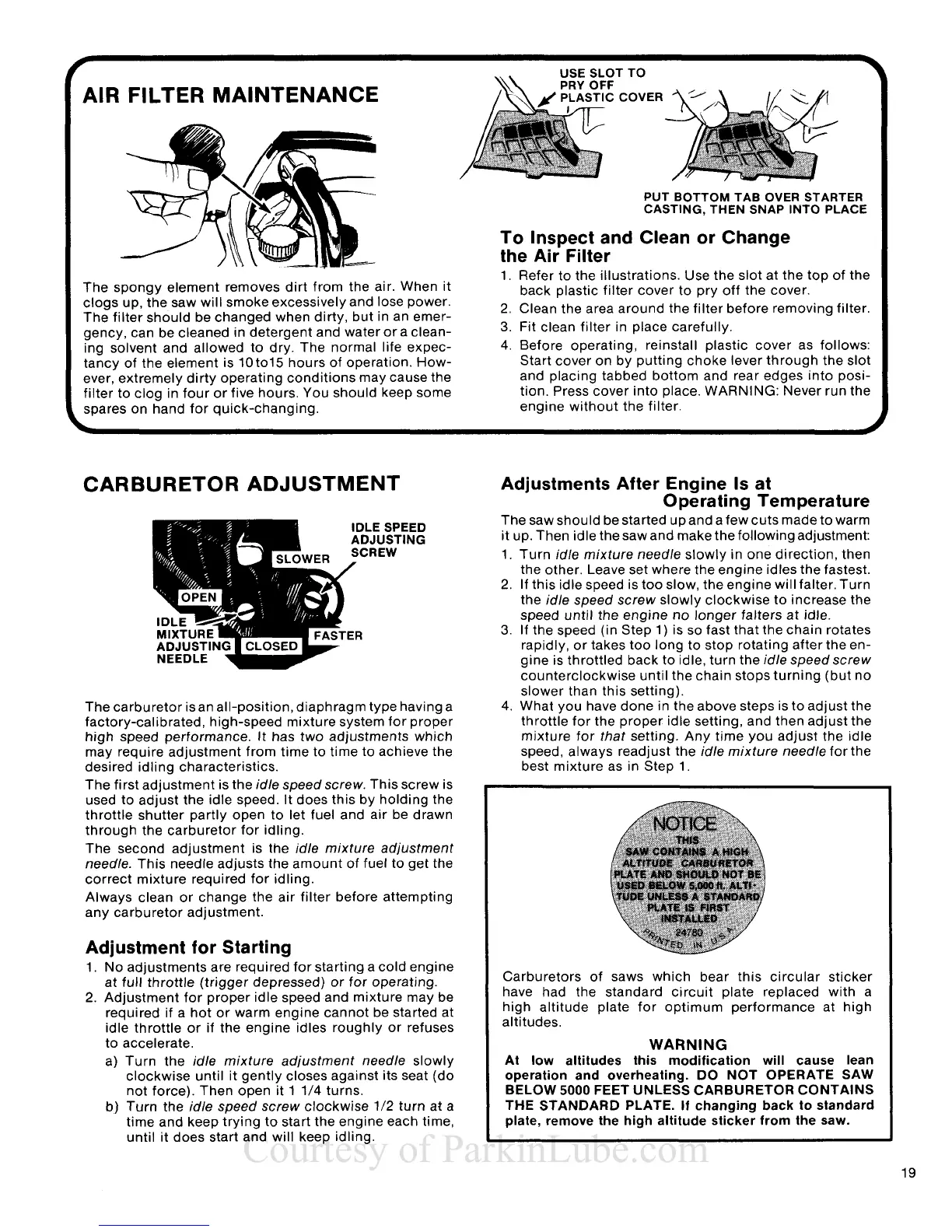

AIR FILTER MAINTENANCE

CASTING, THEN SNAP INTO PLACE

To Inspect and Clean or Change

the Air Filter

1. Refer to the illustrations. Use the slot at the top of the

The spongy element removes dirt from the air. When it

back plastic filter cover to pry off the cover.

clogs up, the saw will smoke excessively and lose power.

2.

Clean the area around the filter before removing filter.

The filter should be changed when dirty, but in an emer-

gency, can be cleaned in detergent and water or a

clean-

3.

Fit clean filter in place carefully.

ing solvent and allowed to dry. The normal life

expec-

4.

Before operating, reinstall plastic cover as follows:

tancy of the element is

lot015 hours of operation. How-

Start cover on by putting choke lever through the slot

ever, extremely dirty operating conditions may cause the

and placing tabbed bottom and rear edges into

posi-

filter to clog in four or five hours. You should keep some

tion. Press cover into place. WARNING: Never run the

spares on hand for quick-changing.

engine without the filter.

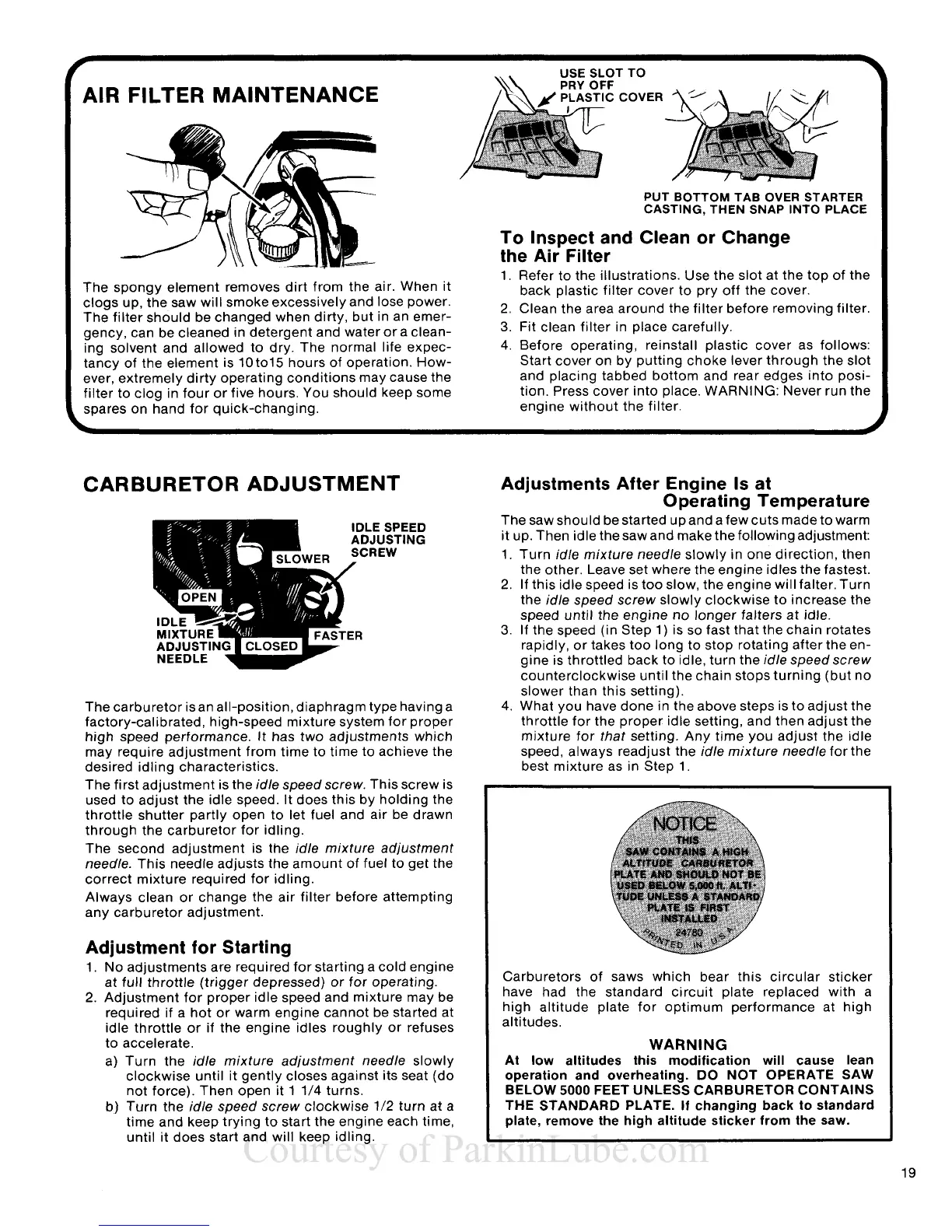

CARBURETOR ADJUSTMENT

The carburetor isan all-position, diaphragm type having a

factory-calibrated, high-speed mixture system for proper

high speed performance. It has two adjustments which

may require adjustment from time to time to achieve the

desired idling characteristics.

The first adjustment is the idle speed screw. This screw is

used to adjust the idle speed. It does this by holding the

throttle shutter partly open to let fuel and air be drawn

through the carburetor for idling.

The second adjustment is the idle mixture adjustment

needle. This needle adjusts the amount of fuel to get the

correct mixture required for idling.

Always clean or change the air filter before attempting

any carburetor adjustment.

Adjustment for Starting

-

1. No adjustments are required for starting a cold engine

at full throttle (trigger depressed) or for operating.

2.

Adjustment for proper idle speed and mixture may be

required if a hot or warm engine cannot be started at

idle throttle or if the engine idles roughly or refuses

to accelerate.

a) Turn the idle mixture adjustment needle slowly

clockwise until it gently closes against its seat (do

not force). Then open it 1 1/4 turns.

b) Turn the idle speed screw clockwise 1/2 turn at a

time and keep trying to start the engine each time,

until it does start and will keep idling.

Adjustments After Engine Is at

Operating Temperature

The saw should be started up and a few cuts made to warm

it up. Then idle the saw and make the following adjustment:

1. Turn idle mixture needle slowly in one direction, then

the other. Leave set where the engine idles the fastest.

2. If this idle speed is too slow, the engine will falter. Turn

the idle speed screw slowly clockwise to increase the

speed until the engine no longer falters at idle.

3.

If the speed (in Step 1) is so fast that the chain rotates

rapidly, or takes too long to stop rotating after the en-

gine is throttled back to idle, turn the idle speed screw

counterclockwise until the chain stops turning (but no

slower than this setting).

4.

What you have done in the above steps is to adjust the

throttle for the proper idle setting, and then adjust the

mixture for that setting. Any time you adjust the idle

speed, always readjust the idle mixture needle for the

best mixture as in Step 1.

Carburetors of saws which bear this circular sticker

have had the standard circuit plate replaced with a

high altitude plate for optimum performance at high

altitudes.

WARNING

At low altitudes this modification will cause lean

operation and overheating. DO NOT OPERATE SAW

BELOW

5000

FEET UNLESS CARBURETOR CONTAINS

THE STANDARD PLATE. If changing back to standard

plate, remove the high altitude sticker from the saw.

Loading...

Loading...