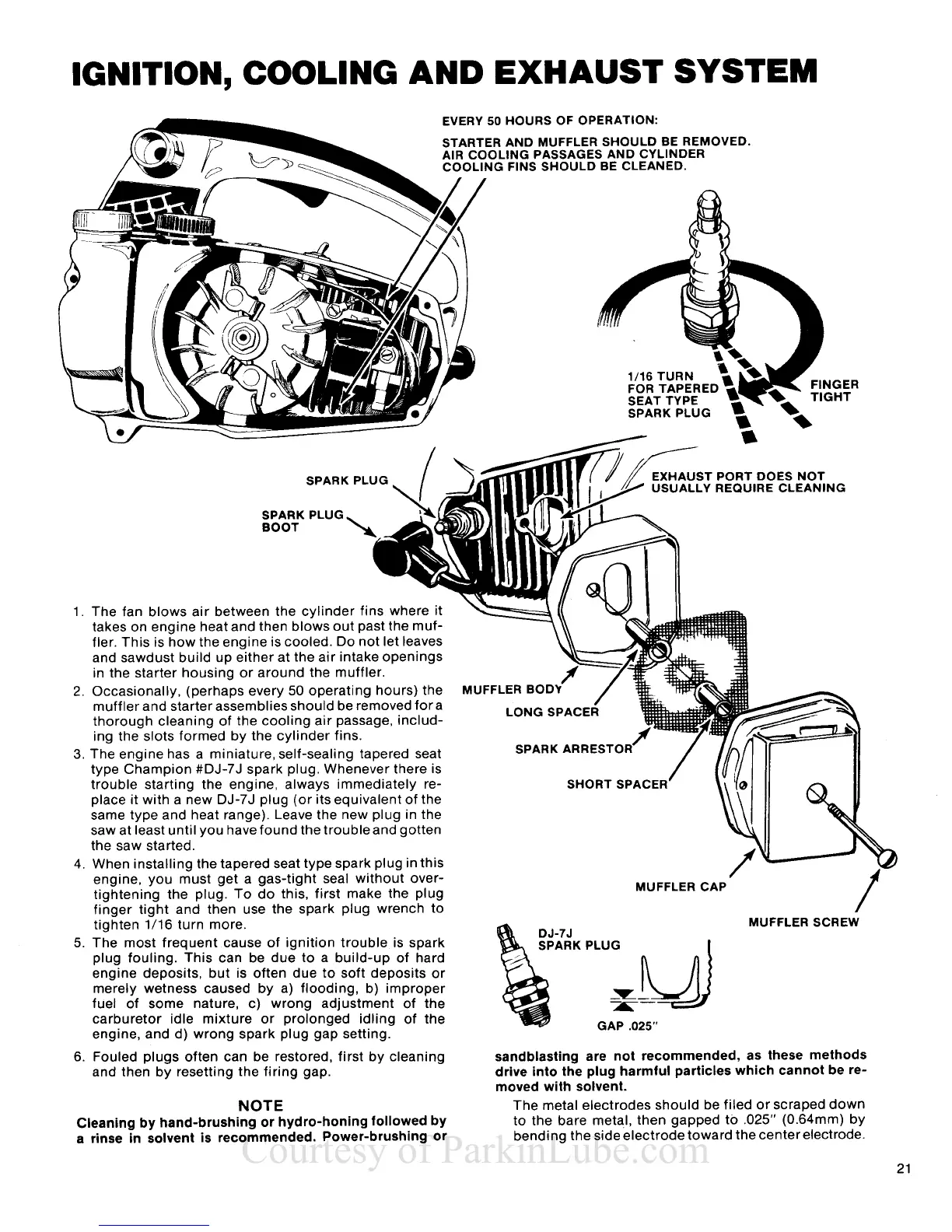

IGNITION, COOLING AND EXHAUST SYSTEM

HOURS OF OPERATION:

AND MUFFLER SHOULD BE REMOVED.

ING PASSAGES AND CYLINDER

FINS SHOULD BE CLEANED.

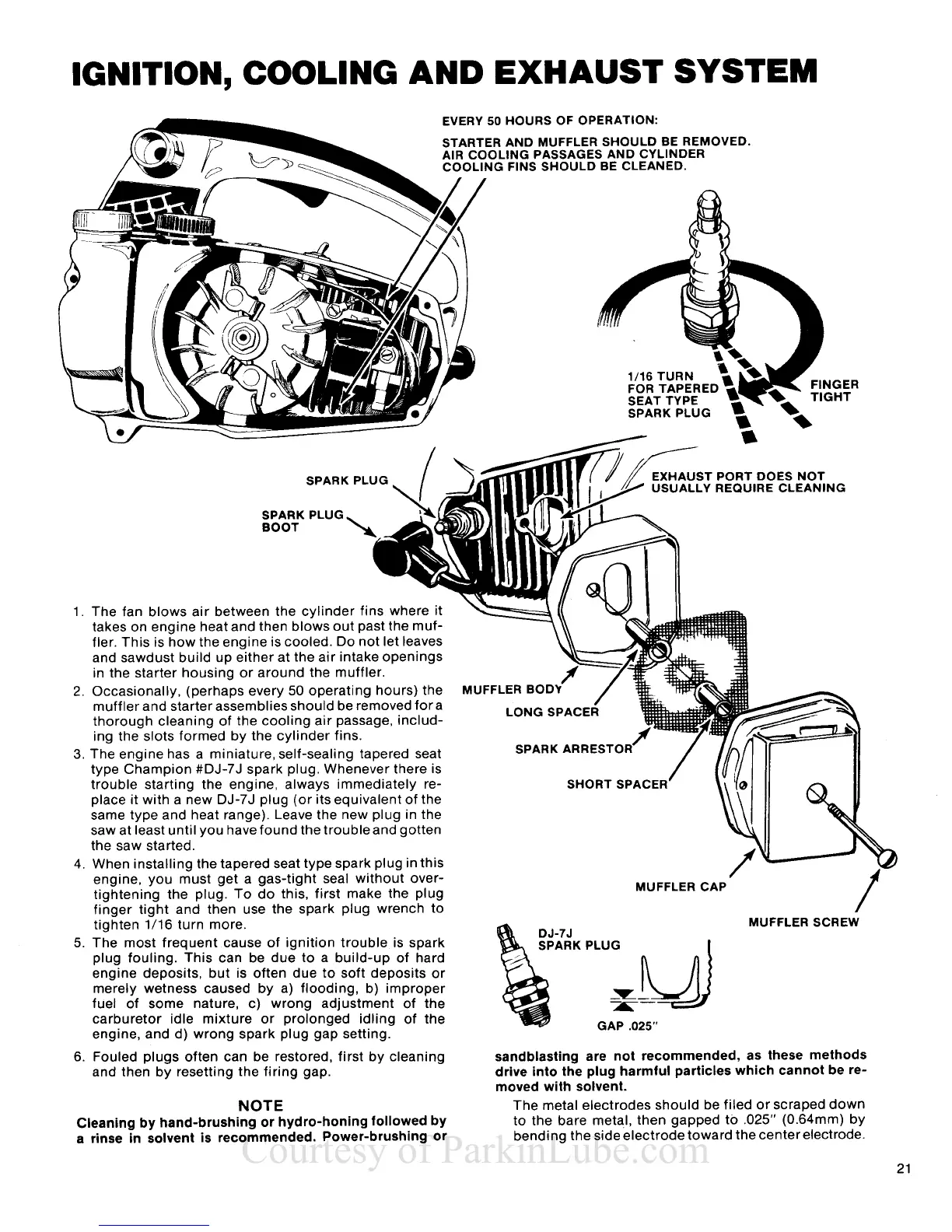

SPARK PLUG

T PORT DOES NOT

Y REQUIRE CLEANING

in the starter housing or around the muffler.

2.

Occasionally, (perhaps every 50 operating hours) the

MUFFLER BOD

muffler and starter assemblies should be removed fora

LONG SPACE

thorough cleaning of the cooling air passage, includ-

ing the slots formed by the cylinder fins.

3.

The engine has a miniature, self-sealing tapered seat

SPARK ARRESTOR

type Champion #DJ-7J spark plug. Whenever there is

trouble starting the engine, always immediately

re-

SHORT SPACER

place it with a new DJ-7J plug (or its equivalent of the

same type and heat range). Leave the new plug in the

saw at least until you have found the troubleand gotten

the saw started.

4. When installing the tapered seat type spark plug in this

engine, you must get a gas-tight seal without over-

tightening the plug. To do this, first make the plug

MUFFLER CAP

finger tight and then use the spark plug wrench to

tighten 1/16 turn more.

MUFFLER SCRE

5. The most frequent cause of ignition trouble is spark

plug fouling. This can be due to a build-up of hard

engine deposits, but is often due to soft deposits or

merely wetness caused by a) flooding, b) improper

fuel of some nature, c) wrong adjustment of the

carburetor idle mixture or prolonged idling of the

engine, and d) wrong spark plug gap setting.

GAP

.025"

6.

Fouled plugs often can be restored, first by cleaning

sandblasting are not recommended, as these methods

and then by resetting the firing gap.

drive into the plug harmful particles which cannot be

re-

moved with solvent.

NOTE

The metal electrodes should be filed or scraped down

Cleaning by hand-brushing or hydro-honing followed by

to the bare metal, then gapped to

,025"

(0.64mm) by

a rinse in solvent is recommended. Power-brushing or

bending the side electrode toward the center electrode.

Loading...

Loading...