GB-6

GB

Connecting the piping

WARNING

In order to ensure that the gas meter is tight:

– The pressure test nipple must not be twisted,

bent, or otherwise manipulated.

– When installing, always secure the pressure test

nipple using a suitable spanner.

▷

Functional safety and reliability are ensured only if

the material combination of the screw connector

and the pressure line are inter-matched.

▷

Only use the olive and the attached union nut

supplied. The olive is secured to the sealing

sleeve.

▷

When re-ordering, use original Parker EO pro-

gressive ring fittings PSR/DPR.

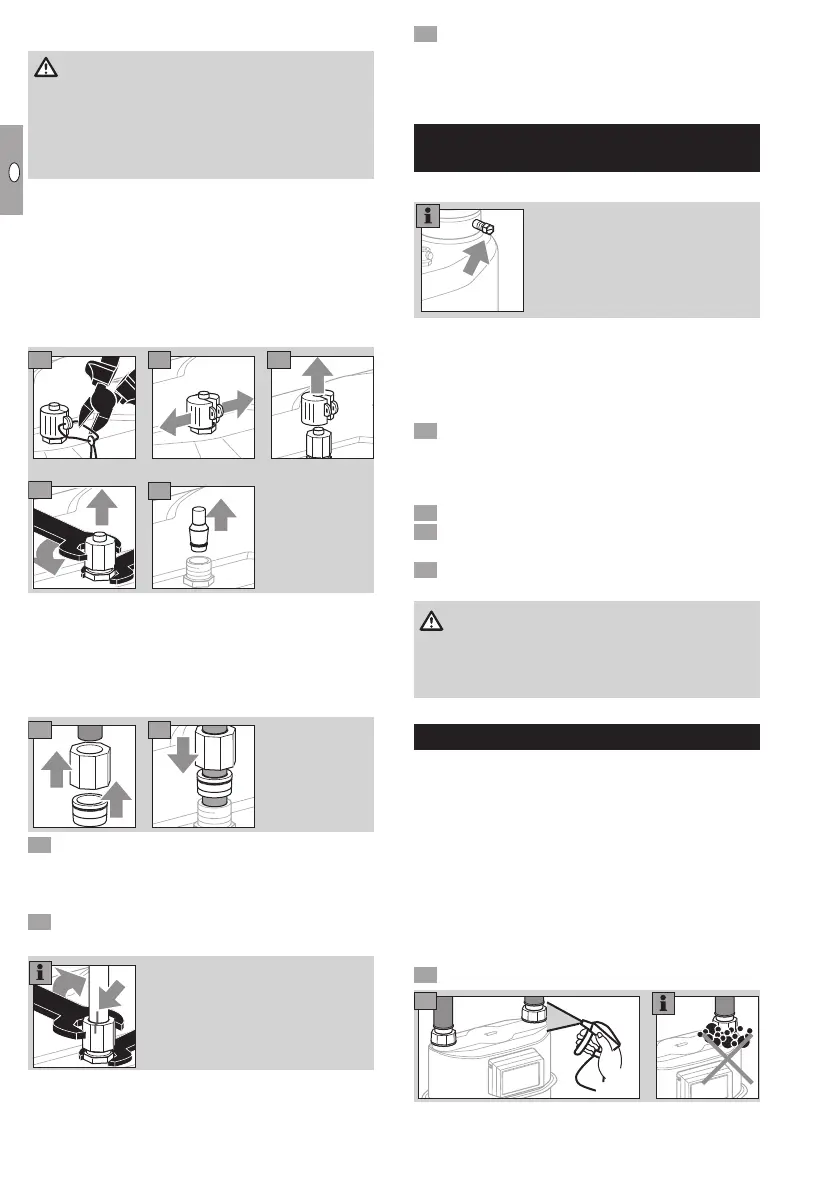

1

2

3

4

5

▷

Use corrosion-resistant, seamless precision steel

tube pursuant to DINEN10305-4 (external di-

ameter 6mm, material E235= 1.0308). For other

materials, use a suitable adapter and note the

Parker/EO recommendations.

▷ Install pipes free of mechanical stress.

6

7

8 Screw on the union nut by hand as far as it will

go.

▷

At the same time, press the end of the pipe firmly

against the stop.

9 Mark the position of the union nut and tighten

with about 1½ turns.

▷

When reinstalling, the union nut will be turned to

the original position and then further tightened

through approx. 30°.

0 Once the installation and tightness test are com-

plete, see page6 (Tightness test), protect the

pressure test point against external access with

the sealing sleeve and the seal.

Pressure test point on outlet

connector (optional)

BS4161-compliant pressure test nipple

▷

Use a 10 mm spanner to release/tighten the

test point screw.

▷

The test nipple is secured to prevent it turning

with the screw.

Opening the test nipple

Remove the screw from the test nipple com-

pletely.

▷ The gas connection is open.

Closing the test nipple

Insert the screw by hand as far as possible.

Tighten the screw with a torque of 3Nm +

0.5Nm.

Check for tightness, see page 6 (Tightness

test).

WARNING

If the test nipple has unexpectedly come loose,

the gas meter must be regarded as damaged and

must be replaced.

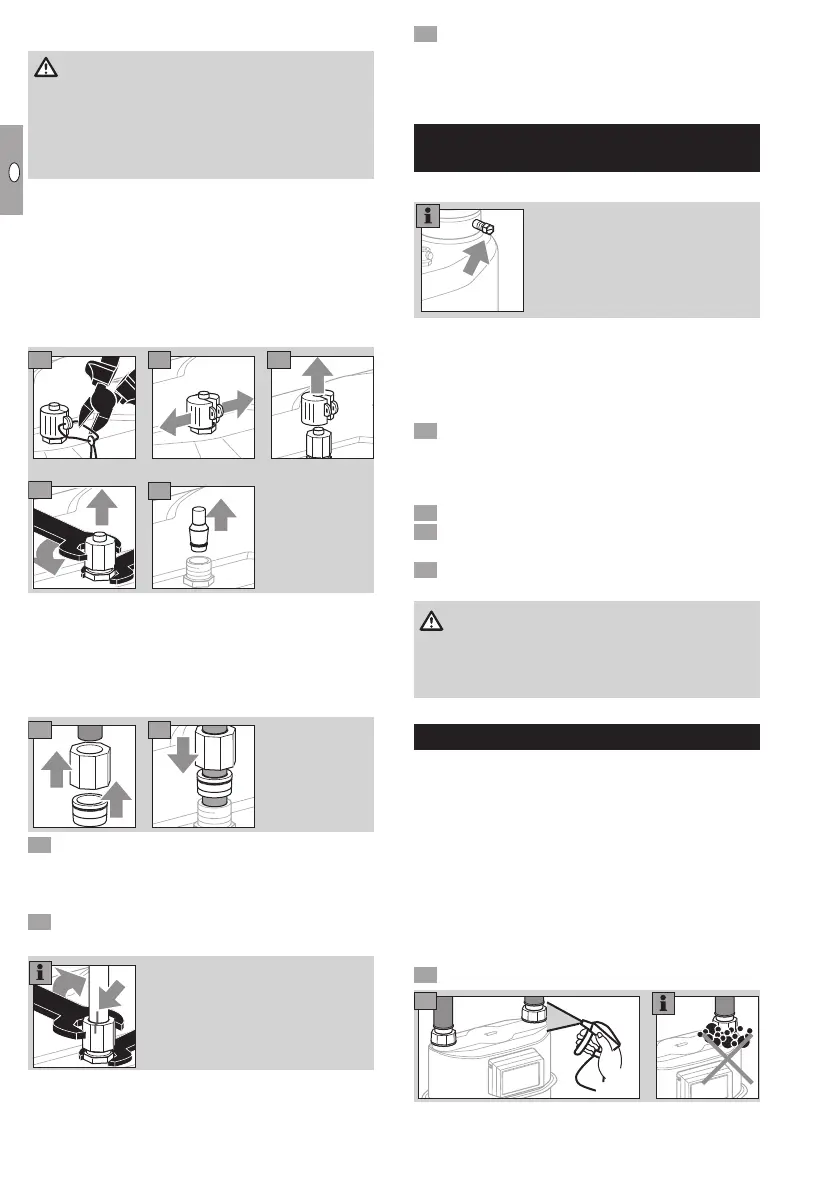

Tightness test

▷

Check the pipework for leaks prior to installa-

tion of the gas meter, in case the pipework is

tested with a greater test pressure than the max.

allowable operating pressurep

max

for the gas

meter. Otherwise, the installed gas meter may

be damaged.

▷ If a valve is integrated in the diaphragm gas me-

terBK, see page 3 (Diaphragm gas meters

with integrated valve), this must be opened for

the tightness test.

▷ Ensure the customer’s consumers are closed.

Apply the test pressure slowly to the gas meter.

▷ If a pressure measuring line has been retrofitted

to the diaphragm gas meter, check this connec-

tion for tightness.

Loading...

Loading...