Do you have a question about the Honeywell ML7284 and is the answer not in the manual?

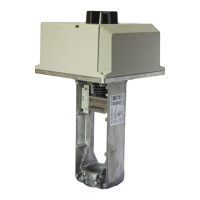

The Honeywell ML7284 Non-Spring Return Direct Coupled Damper Actuator is designed for proportional control of dampers in heating, ventilation, and air conditioning (HVAC) applications. It accepts a current or voltage signal from an electronic controller to position a damper at any point between fully open and fully closed.

The ML7284 operates by driving the damper shaft either clockwise (cw) or counter-clockwise (ccw), depending on the damper design. Most actuators are shipped in the fully counter-clockwise position. When used with a proportional controller, the actuator moves towards its fully open position as the input signal increases and towards its fully closed position as the input signal decreases. The actuator stops when the input signal reaches the desired proportional control point. A rotation reversal slide switch on the side of the actuator housing allows for easy reversal of the actuator's rotation. For example, in the direct position, 2 volts corresponds to closed and 10 volts to open, while in the reverse position, 2 volts corresponds to open and 10 volts to closed.

The ML7284D and ML7284F models include a time-out function that removes power from the actuator submotor if the actuator remains in the fully open or fully closed position for longer than a nominal 5 minutes. This feature helps to extend the actuator's life.

| Brand | Honeywell |

|---|---|

| Model | ML7284 |

| Category | Controller |

| Language | English |

Loading...

Loading...