Do you have a question about the Honeywell R4795A and is the answer not in the manual?

Details ambient temperature, humidity, vibration, and weather requirements for proper installation.

Instructions for mounting the subbase and connecting electrical wiring to the R4795.

Covers typical wiring hookups, retrofitting guidance, and specific wiring details.

Details on replacing older models, flame detector wiring, and alarm contact connections.

Instructions for securely mounting the R4795 unit onto the Q270 subbase.

Details initial checks to perform before system startup, including wiring and component seating.

Explains how to test flame detector application and identify potential signal issues.

Provides procedure to ensure the pilot flame can safely light the main burner.

Describes tests for proper system response to limit action, flame failure, and power failure.

Describes the sequence of events during a normal call for heat and burner operation.

Details system responses to safety conditions like flame failure, airflow failure, and timer issues.

Checks for proper seating of components and tight mounting screws before troubleshooting.

Lists common problems and their corresponding troubleshooting steps.

Provides general guidelines for servicing heating equipment and controls safely and effectively.

Outlines recommended maintenance tasks and their frequency for optimal system performance.

Instructions and precautions for cleaning relay contacts using approved cleaners.

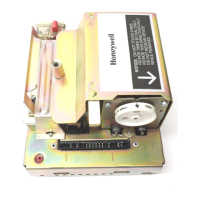

| Brand | Honeywell |

|---|---|

| Model | R4795A |

| Category | Control Unit |

| Language | English |

Loading...

Loading...