RM7838B, RM7838C 7800 SERIES RELAY MODULES

32-00211—01 12

D. MV1 is commanded to be open while MV2 remains

closed, to pressurize the space. After 4 seconds, MV1 is

commanded closed again.

E. This is followed by a three second delay, during

which the valve proving pressure switch (VPS) is

ignored.

F. Thereafter, the VPS is monitored for the duration of

the valve proving test time and, if it turns off, then a

lockout occurs. (Because the gas pressure has

decreased due to a leaky downstream valve.) (High

pressure test.)

Pressure Switches for Valve Proving

System

The Valve Proving System requires a pressure switch to be

installed to monitor the pressure in the internal space

between the two shutoff valves. Some recommended

pressure switches are the following Honeywell non-

manual reset models:

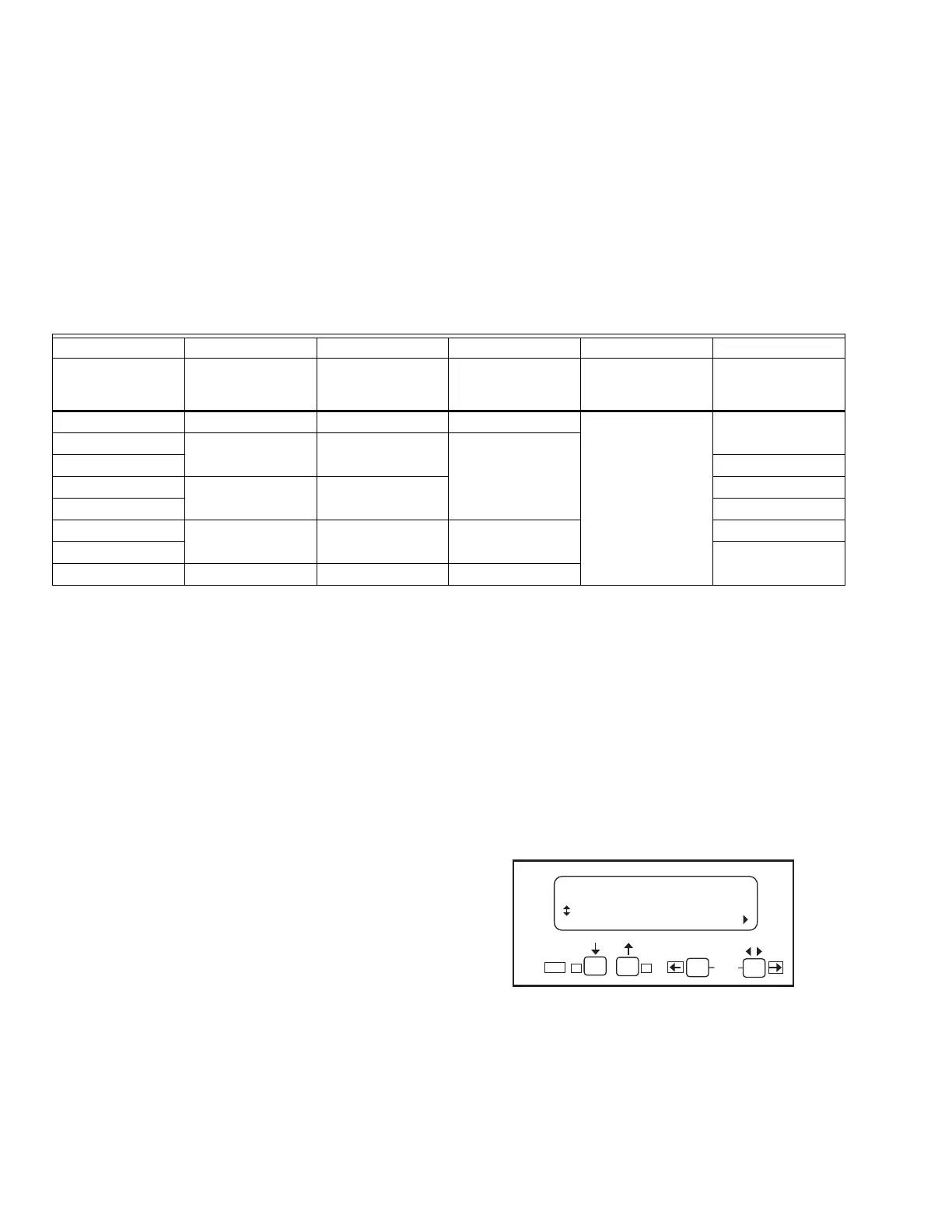

Table 7. Honeywell Pressure Switch Selection for Valve Proving System.

Pressure Switch Selection

1. Determine the maximum operating inlet pressure for

the upstream valve; for example, 5.0 psi (140 in. wc).

2. Divide the inlet pressure by two (2.5 psi [70 in. wc],

for example).

3.

From column 2 in Table 7 find the operating range

upper limit that is closest to but greater than the inlet

pressure divided by two. In the example given, the

possible selections from column 1 are the

C6097A1129 and C6097A1137 with an operating

range upper limit of 7 psi. (The C6097A1079 and

C6097A1087 with an upper limit of 60 in. wc are

close, but 60 in. wc is less than the 70 in. wc mini-

mum, so the next higher range must be selected.)

4. From column 6, select the preferred mounting type,

1/4 in. NPT or Flange. For example, if a flange mount

is required, the pressure switch choice from column

1 would be the C6097A1137.

Pressure Switch Installation and

Adjustment

1. Refer to the instructions for the C6097A Pressure

Switch, form number 65-0237.

2. Install the C6097A Pressure Switch according to the

instructions.

3. Adjust the setpoint to 50% of the maximum operat-

ing inlet pressure for the upstream valve.

4. Complete the operation and checkout procedures in

the instructions.

Setup of Valve Proving Function

Prior to setup of the Valve Proving Function, follow the

procedures in the appendix to complete the worksheet

and obtain the Valve Proving Test Time.

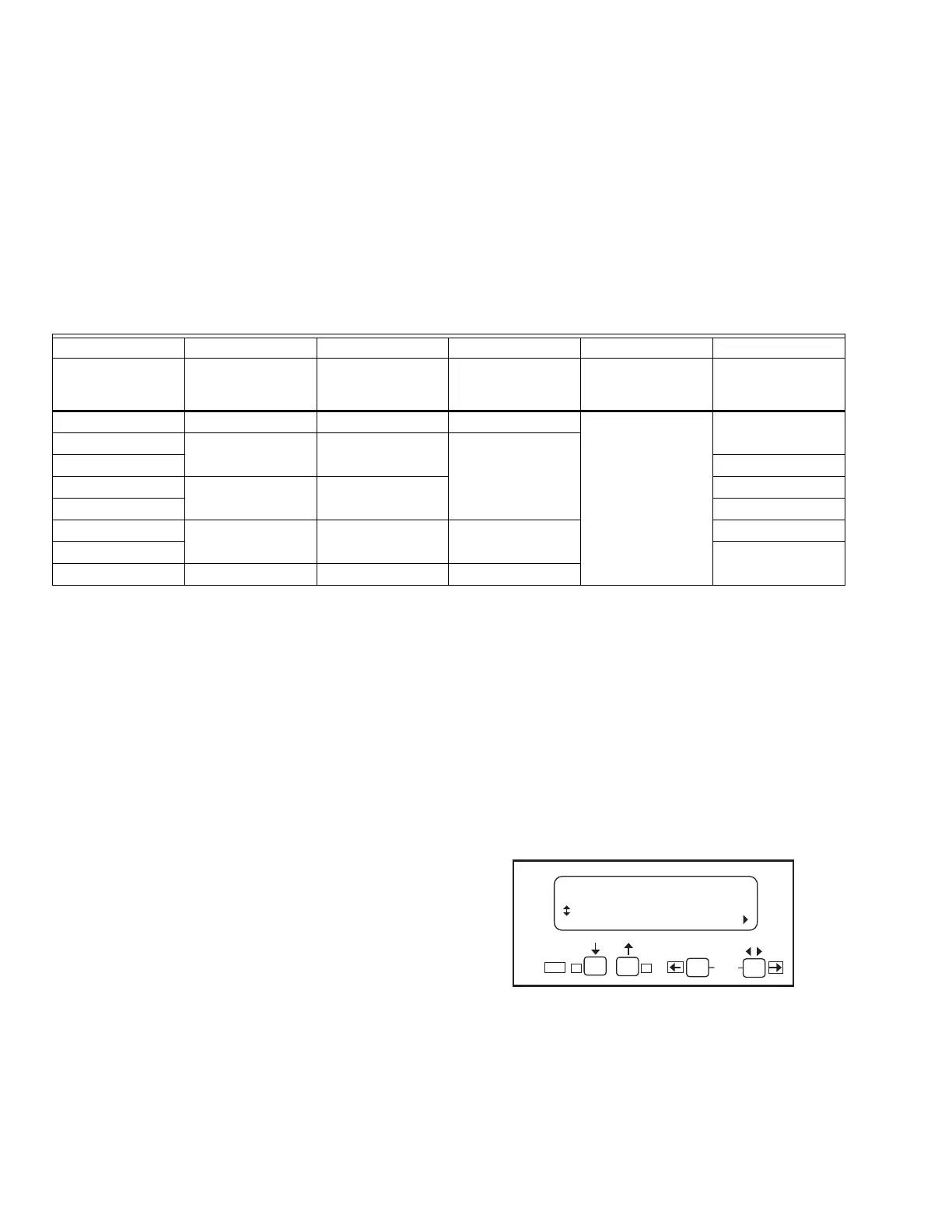

An S7800A1142 Keyboard Display Module (KDM) is

required for this setup and the RM7838 must have the

Valve Proving function.

When the RM7838 is installed and powered, “STANDBY”

will be shown on the first line of the display.

1. Scroll down until the “Setup” is displayed in the sec-

ond line. (Setup is only available when the control is

in Standby or Lockout state.)

Fig. 6. STANDBY/Setup screen.

2. Enter the Setup submenu by pressing the far right

key on the display. Note that the second line now

reads “BC Password”.

123456

Model Number

Operating

Pressure Range

Maximum

Differential

(Additive)

Maximum

Continuous Rated

Pressure (psi)

Switch Action at

Setpoint Mounting Type

C6097A1004 0.4 to 5 in. wc 0.24 in. wc 2.9 Breaks N.O. to C

connection on

pressure fall.

1/4 in. NPT

C6097A1053 3 to 21 in. wc 0.48 in. wc 5.0

C6097A1061 Flange

C6097A1079 12 to 60 in. wc 2.4 in. wc 1/4 in. NPT

C6097A1087 Flange

C6097A1129 1.5 to 7 psi 0.3 psi 9.3 1/4 in. NPT

C6097A1137 Flange

C6097A1210 0.4 to 4 in. wc 0.24 in. wc 2.9

STANDBY

Setup

M22662B

BACK

ENTER

Edit:

-+

Loading...

Loading...