RM7838B, RM7838C 7800 SERIES RELAY MODULES

32-00211—01 4

Relay Module and Subbase

Compatiblity

NOTE: There are several different subbase models that

can be purchased. It is important to note which

subbase is compatible with the relay module

when purchasing new, repair or replacement

parts.

Series 1000 Relay Modules

All relay product codes that start with a 1 (example:

RM7840G1

014/U) can be used with existing subbase

Q7800A1003/U and Q7800A1005/U.

Series 2000 Relay Modules

All relay product codes that start with a 2 (example:

RM7840G2

014/U) must be used with subbase

Q7800A2003/U and Q7800A2005/U.

Subbase Compatibility

Any Relay Module in the 1000 Series with a Software

Revision level number starting with a "5" or greater will be

compatible with all subbase models both installed and

newly purchased. This includes (Q7800A1005/U,

Q7800B1003/U), and the 2000 Series subbases

(Q7800A2005/U, Q7800B2003/U).

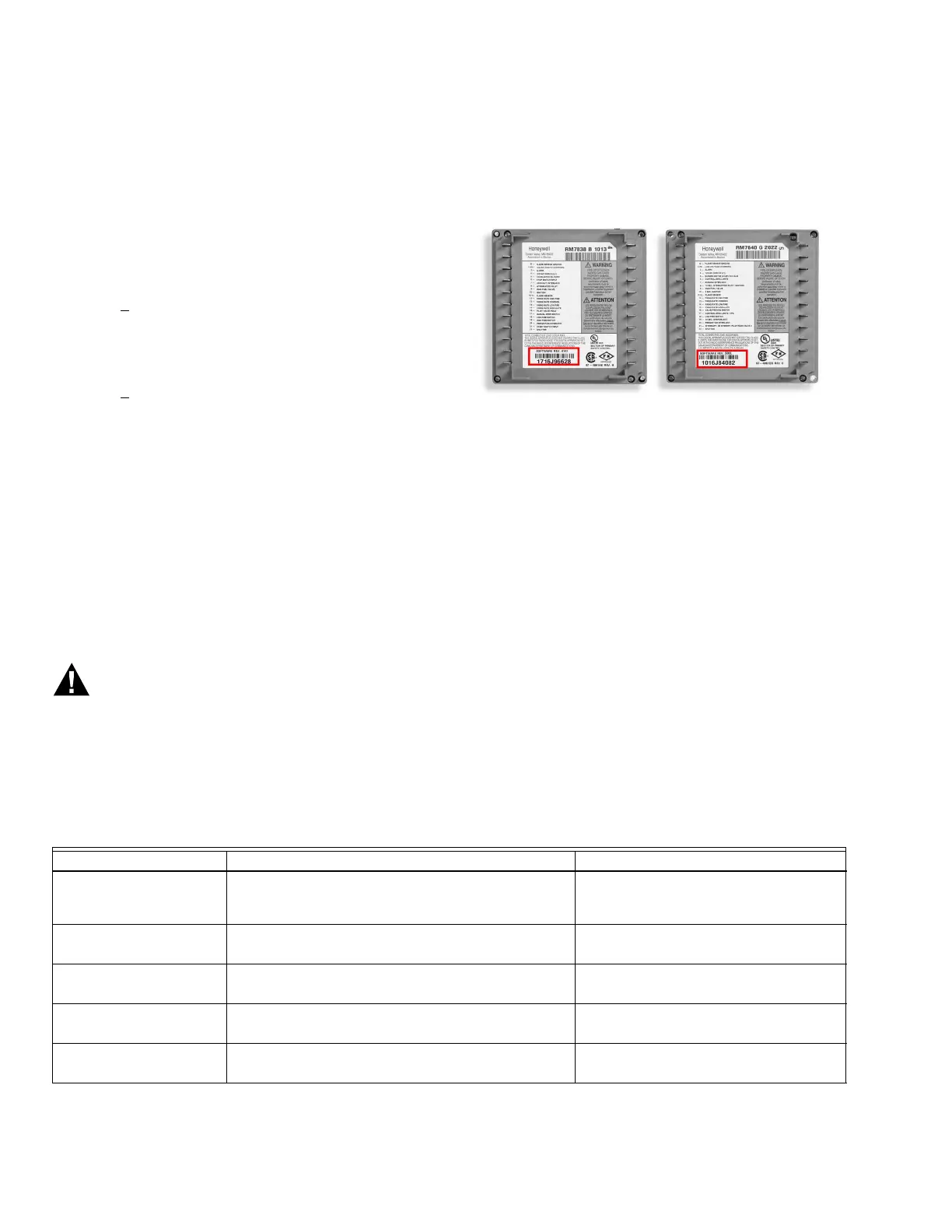

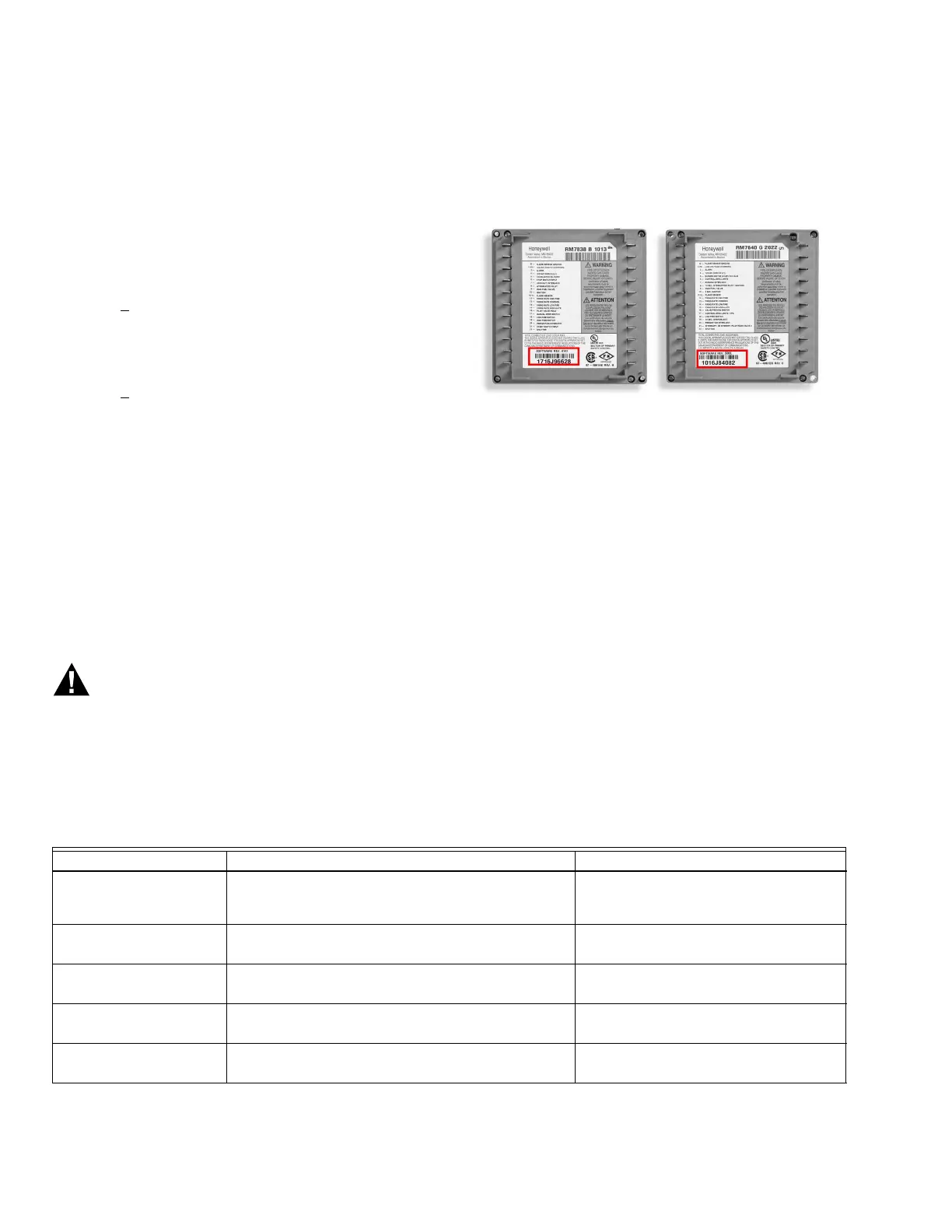

See Fig. 2 for Software Revision Level number location on

the label (located on the rear of the relay module).

Any relay module in the new 2000 series will only be able

to be installed on subbase Q7800A2005/U,

Q7800B2003/U and will not be backward compatible with

any Q7800A1003/U and Q7800A1005/U subbases

already installed in the field.

Fig. 2. Software revision location.

IMPORTANT

Make sure to check the relay model number and

the software revision level on the relay.

• If you attempt to place a 2000 series relay on a non-

compatible 1000 series subbase, you will receive an

error code of 101. This indicates that you must a)

change out the subbase to a Q7800A2003/U or

Q7800A2005/U or b) choose a compatible 1000 series

relay module.

Wiring Subbase

Electrical Shock Hazard.

Can cause serious personal injury, death or

equipment damage.

Disconnect the power supply before beginning

installation. More than one power supply

disconnect may be required.

1. Refer to Fig. 4 for proper subbase wiring.

2. For proper remote wiring of the KDM, refer to the

KDM Specifications (65-0288), Data ControlBus

Module™ (65-0091) or Extension Cable Assembly

(65-0131).

3. Make sure all wiring complies with all applicable

electrical codes, ordinances and regulations. Wiring,

where required, must comply with NEC, Class 1

(Line Voltage) wiring.

4. See Table 1 for recommended wire size and type.

Table 1. Recommended Wire Sizes and Part Numbers.

The KDM or Data ControlBus Module™ (for remote

mounting or communications) must be wired in a daisy

chain configuration,

1(a)-1(a), 2(b)-2(b), 3(c)-3(c). The order of interconnection

of all the devices listed above is not important. Be aware

that modules on the closest and farthest end of the daisy

Application Recommended Wire Size Recommended Part Numbers

Line voltage terminals

14, 16 or 18 AWG (0.75, 1.5 or 2.5 mm

2

) copper

conductor, 600 volt insulation, moisture-resistant

wire.

TTW60C, THW75C, THHN90C.

KDM

22 AWG (0.34 mm

2

) two-wire twisted pair with

ground, or five-wire.

Belden 8723 shielded cable or

equivalent.

Data ControlBus

Module™

22 AWG (0.34 mm

2

) two-wire twisted pair with

ground, or five-wire.

Belden 8723 shielded cable or

equivalent.

Remote Reset Module

22 AWG (0.34 mm

2

) two-wire twisted pair, insulated

for low voltage.

—

13 Vdc full wave rectified

transformer power input.

18 AWG (0.75 mm

2

) wire insulated for voltages and

temperatures for given application.

TTW60C, THW75C, THHN90C.

Loading...

Loading...