9 63-2489

T775A,B,C,D

DESCRIPTION/OPERATION

Cooling Mode:

• Stage One: Energized at 70°F.

The T775B,D have dual sensor inputs and allow two

separate controllers to exist within one enclosure. Selection

of the stage parameters (operation mode, setpoints, and

differentials) is the same as for a single sensor device after

each stage is assigned its operating sensor. This assignment

is hardware driven via a four position DIP switch. An

explanation of the DIP switch assignments appears in Fig. 9.

See Fig. 3 and 4 for the DIP switch location.

CONTACT CLOSURE OVERRIDE INPUT

A two-terminal input is provided to allow the user to

override a relay-energized condition on all outputs by using

a contact closure between terminal pins 3 and 4 of the

terminal block for the sensor input shown in Fig. 3 and 4.

This can be achieved manually or by using an EMS control-

ler or time clock with normally open contacts (W7505 or

S7005, for example).

When this override is active, the display will show the

number of the stages that would be energized and the words

STAGE ENERGIZED will flash on the display. The ener-

gized stages will then be de-energized until the override

returns to inactive (Off).

°F/°C SELECTION

A single jumper plug controls °F/°C indication of the

displayed temperature value. The location of this jumper is

shown in Fig. 3 and 4. The unit is shipped with the jumper

installed in the °F mode. To operate the device in the °C

mode, remove the jumper. Replacing the jumper will rein-

state the °F mode.

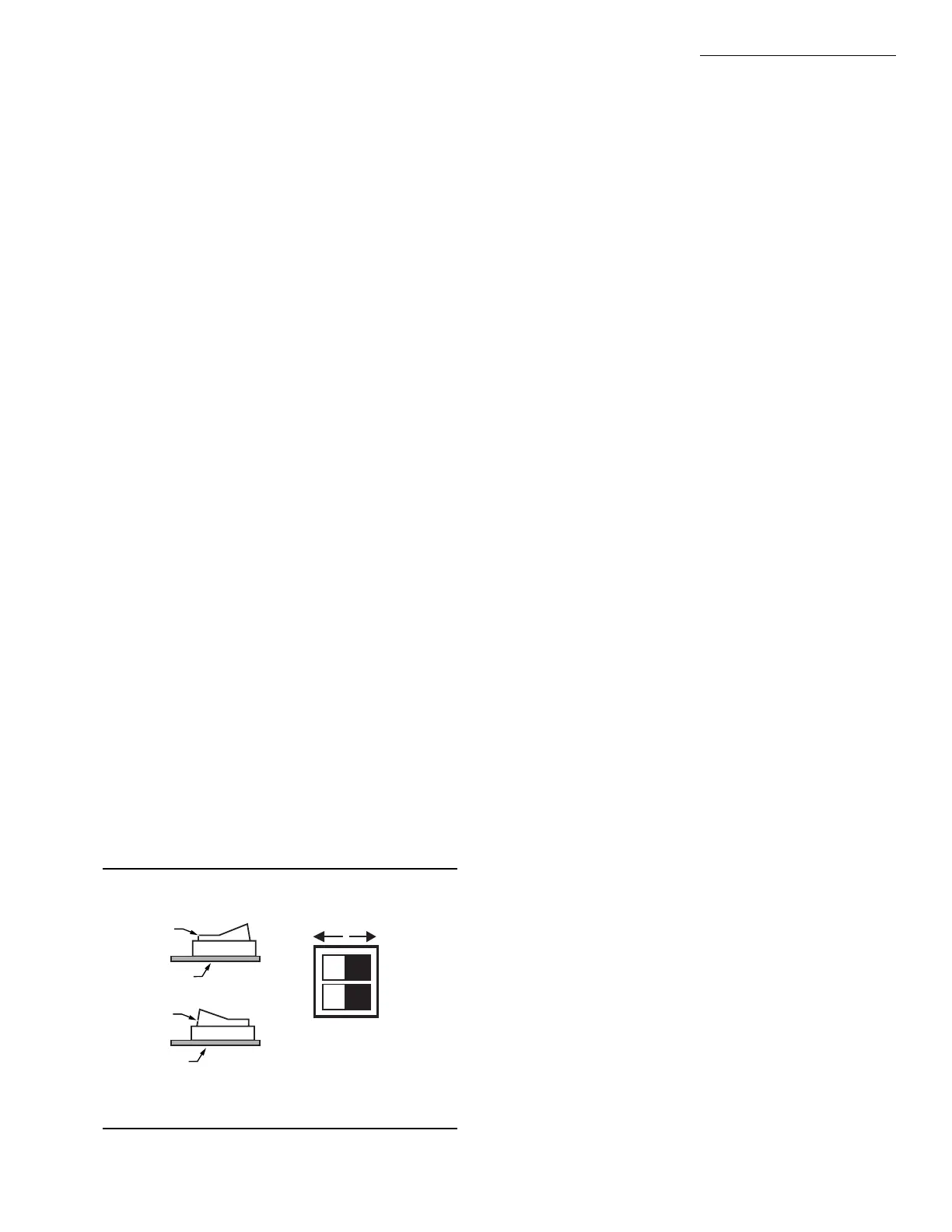

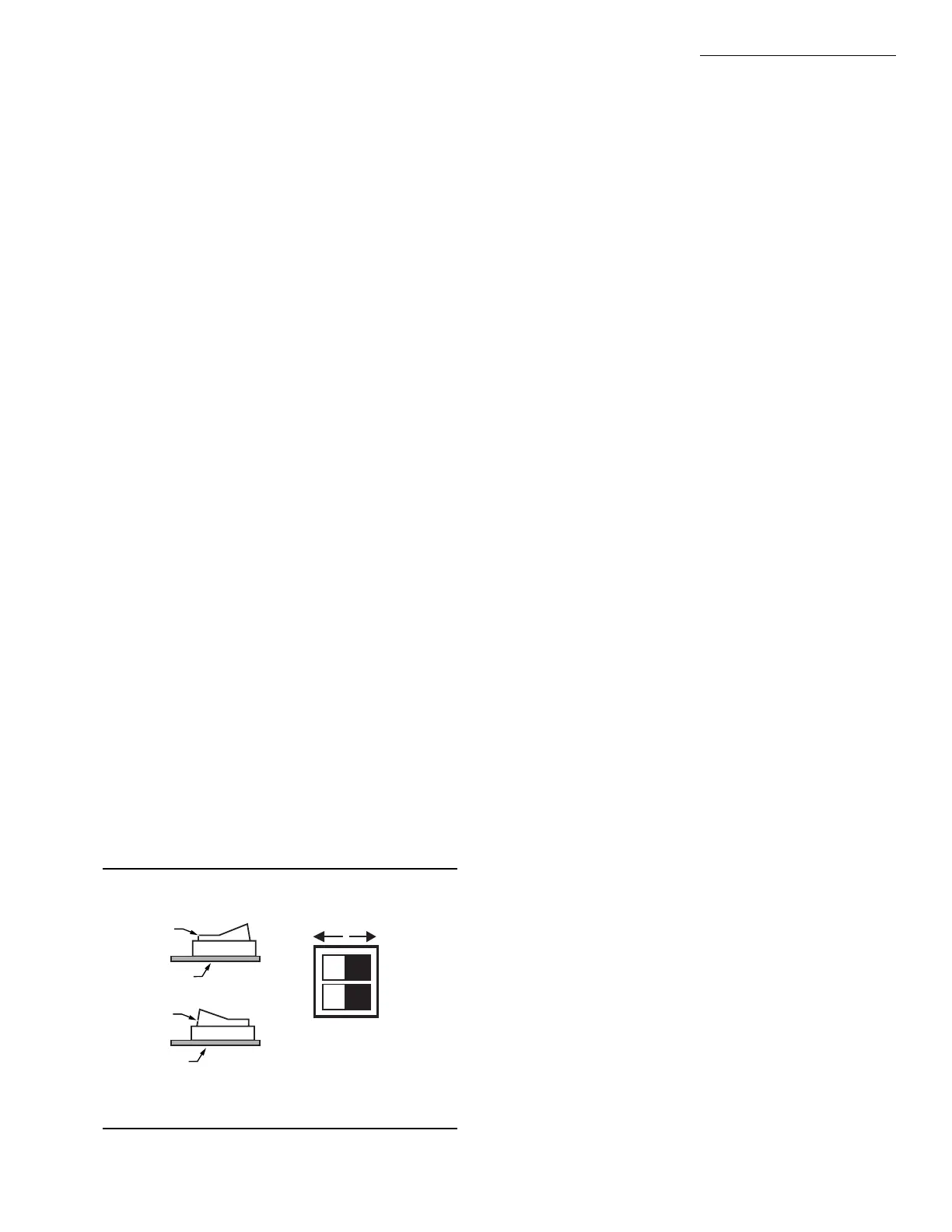

DIP SWITCH SELECTIONS

On the T775B and D, the DIP switches are provided for

assignment of each relay output stage to its operating sensor.

If an individual switch is depressed toward its correspond-

ing load number (1 through 4 on DIP switch) or to the right,

Sensor B will be the controlling sensor for that output stage.

If an individual switch is depressed to the left, Sensor A will

be the controlling sensor for the output stage. An example of

the switches and their corresponding positioning is shown in

Fig. 9.

Fig. 9—DIP switch settings for sensor selection.

KEYPAD PROGRAMMING AND DISPLAY

The T775 utilizes a Liquid Crystal Display (LCD) for

interactive prompting during programming and display of

sensed and assigned setpoint and differential values. User

programming of the T775 is accomplished through the four

programming keys.

Programming Keys

The four programming keys are the Select, Up arrow,

Down arrow and Enter keys.

• Select key sequentially prompts the user about what

parameter is being displayed: setpoint, differential,

stage energized, heat or cool (operation mode), 1,2,3,4

(indicating assigned stage). After the last parameter

value is viewed, pressing the Select key will again

display the control values from the beginning of the

display loop.

• Up and Down arrow keys allow the displayed param-

eter to be increased or decreased. After pressing the

Select key, a control value can be changed by using the

arrow keys. Control values will be increased or de-

creased by 1°F or 1°C for each time the arrow key is

depressed.

• Enter key places the new value into the memory of the

microprocessor.

IMPORTANT: A control value or operation will not be

entered into the memory of the microprocessor until

the Enter key is pressed.

• Press the Select and Enter keys at the same time to

change the control algorithm from heating to cooling

or from cooling to heating. The heating and cooling

parameters are not displayed during the normal Select

key sequences. The only parameters displayed after

pressing the Select and Enter keys at the same time

will be the stage indication and the word, heat or cool.

To change the operation from heating to cooling or

vice versa for a desired output stage, use the arrow

keys. Once the mode is changed, pressing the Enter

key is necessary to enter this change into the micropro-

cessor memory. The next stage of heat or cool assign-

ment will appear after the Select key is pressed. When

all stages are programmed, the display will revert back

to sensed temperature and load energized status.

Control values and operation selection will remain in the

device memory even after the power is removed.

Display

Once power is applied or restored to the device, the dis-

play will count down from 210 until the display reads zero,

during which time any previously energized outputs will be

de-energized. This is intended to protect compressors in the

event of a power outage.

To avoid viewing this entire countdown, press the Select

key. The LCD display will now show what it normally reads:

load (sensed) temperature, stages energized, and which sen-

sor (Sensor A or Sensor B) is being read for two sensor

M3292

LOAD 1 IS CONTROLLED BY

SENSOR A WHEN SWITCH IS

DEPRESSED ON THE LEFT

LOAD 2 IS CONTROLLED BY

SENSOR B WHEN SWITCH IS

DEPRESSED ON THE RIGHT

(AS SHOWN)

SENSOR A SENSOR B

LOAD 1

LOAD 2

SIDE VIEW

AB

SWITCH

SWITCH

PWB

PWB

Loading...

Loading...