Do you have a question about the Honeywell VR8215 Series and is the answer not in the manual?

Safety warnings about property damage, severe injury, or death.

Control wear due to high cycling rates; requires monthly checkout.

Protect control from water/steam during cleaning procedures.

Protect control from moisture, ensure air circulation to prevent condensation.

Protect control from chemical exposure that causes failure.

Provide covers to limit contamination from dust/grease.

Protect control from excessive temperatures by ensuring ambient temp is within rating.

Safety warnings about property damage, severe injury, or death during installation.

Safety warnings related to gas conversion hazards.

Steps for installing bushings onto the gas control inlet/outlet.

Guidance on optimal placement of the gas control within the appliance.

Instructions for connecting gas piping or tubing to the control.

Steps for mounting and connecting the gas control itself.

Safety warnings about injury, death, or equipment damage from electrical issues.

Operation of the on-off switch for controlling main gas flow.

Procedure to detect gas leaks after installation or service.

Steps to put the system into an operational state.

Instructions for activating the main burner.

Procedures for checking and adjusting gas input and burner ignition for specific models.

Safety warnings for performing the safety shutdown test.

Safety warnings against disassembling or repairing the gas control.

Warning against shorting valve coil terminals, which can damage components.

Safety warnings regarding disassembly, repair, or cleaning of the control.

Troubleshooting steps for when the main burner fails to ignite.

Safety warnings for homeowners, including gas leak procedures.

Mandatory safety instructions before operating the appliance.

Procedure for setting the thermostat for vacation shutdown.

Steps to completely turn off power and gas supply to the appliance.

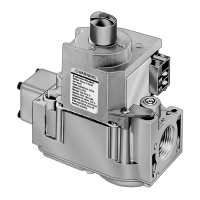

The Honeywell VR8215S,T is a Direct Ignition Combination Gas Control designed for use in gas-fired appliances. It integrates a switch and a pressure regulator, optimized for direct ignition systems.

The VR8215S,T controls the flow of gas to the main burner in gas-fired appliances. It is specifically designed for direct ignition applications, where an igniter directly lights the main burner without a standing pilot. The control includes a pressure regulator to maintain a consistent gas pressure to the burner and an on-off switch for manual gas flow control. It is suitable for both natural gas and LP gas applications, with conversion kits available for switching between gas types. The control is designed to operate in conjunction with a direct ignition module (e.g., S87B, S89C,G,J/S890C,G,J Hot Surface Ignition Control) and a thermostat or controller.

| Brand | Honeywell |

|---|---|

| Model | VR8215 Series |

| Category | Control Unit |

| Language | English |

Loading...

Loading...