69-0624—2 4

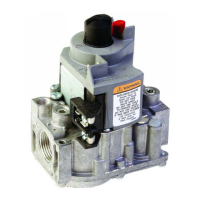

Fig. 5—Proper use of wrench on gas control.

APPLY WRENCH

FROM TOP OR

BOTTOM OF GAS

CONTROL TO

EITHER SHADED AREA

WHEN FLANGE IS NOT USED

APPLY WRENCH

TO FLANGE ONLY

WHEN FLANGE IS USED

M3083

Connect Pilot Gas Tubing

1. Cut tubing to desired length and bend as necessary for

routing to pilot burner.

CAUTION

Do not make sharp bends or deform the tubing. Do

not bend tubing at gas control or pilot burner after

compression fitting is tightened, because this may

result in gas leakage at the connection.

2. Square off and remove burrs from the end of the

tubing.

3. Unscrew compression fitting from the pilot outlet

(Fig. 4). Slip the compression fitting over the tubing and

slide out of the way.

NOTE: When replacing a gas control, cut off old compres-

sion fitting and replace with the new compression fitting

Fig. 4—Top view of gas control.

OUTLET

PRESSURE

TAP

INLET

OUTLET

WIRING

TERMINALS (3)

INLET

PRESSURE TAP

PRESSURE REGULATOR

ADJUSTMENT

(UNDER CAP SCREW)

PILOT OUTLET

PILOT ADJUSTMENT

(UNDER CAP SCREW)

GAS

CONTROL

KNOBRED RESET BUTTON

M1639C

GAS CONTROL

TIGHTEN NUT ONE TURN

BEYOND FINGER TIGHT

FITTING BREAKS OFF AND CLINCHES

TUBING AS NUT IS TIGHTENED

TO

BURNER

M3076A

provided on the gas control. Never use the old compres-

sion fitting because it may not provide a gas-tight seal.

4. Push tubing into the pilot gas tapping on the outlet end

of the control until it bottoms. While holding tubing all the

way in, slide compression fitting into place and engage

threads—turn until finger tight. Then tighten one more turn

with a wrench. Do not overtighten. See Fig. 6.

5. Connect the other end of the tubing to the pilot burner

according to the pilot burner manufacturers instructions.

Connect Thermocouple

Connect thermocouple lead as shown in Fig. 7. See

Tables 6 and 7. This is an electrical connection and must be

clean and dry. Never use pipe compound. Tighten only 1/4

turn beyond finger tight to give good electrical continuity.

Do not overtighten.

Fig. 6—Always use new compression fitting.

Loading...

Loading...