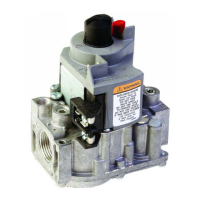

The Honeywell V800 Family of Combination Gas Controls are designed to perform all necessary functions within the burner manifold of gas-fired heating equipment. These controls are suitable for a wide range of applications, from small individual room heaters to large central heating units.

Function Description:

The V800 family provides a 3-position (OFF-PILOT-ON) manual control for gas flow. In the OFF position, both the manual safety shutoff valve and the main valve are closed, preventing any gas flow into the control. In the PILOT position, the manual safety shutoff valve opens when the knob is depressed, allowing pilot gas to flow for ignition. After approximately one minute, the thermocouple/generator generates enough current to hold the safety shutoff valve open, while the main valve remains closed, preventing main burner gas flow until a call for heat. In the ON position, when there is no call for heat, the safety shutoff valve is open, but the main valve remains closed, restricting gas flow to the pilot only. When the thermostat calls for heat, the valve operator opens the left-hand port and closes the right-hand port. Gas flows through the working gas channel, increasing pressure, which pushes against the main valve diaphragm, opening the main valve and allowing gas flow to the main burner. The servo pressure regulator then controls the outlet gas pressure to the main burner. If the thermostat ends the call for heat, the valve operator closes the left-hand port and opens the right-hand port, reversing gas flow through the working gas channel, decreasing pressure, and allowing the main valve diaphragm to retract and close the main valve.

The Pilotstat safety shutoff mechanism ensures that if the pilot flame extinguishes or becomes too small for proper ignition, the combination gas control shuts down. The thermocouple or Powerpile generator, heated by the pilot flame, provides current to the Pilotstat power unit to keep the safety valve open. If the pilot goes out or current decreases, the power unit "drops out," closing the safety valve and preventing both pilot and main burner gas flow. To restart, the pilot flame must be manually relit and the Pilotstat manually reset. VS820 and VS821 Powerpile models are unique in that they generate current independently of line voltage, allowing them to continue regulating pilot and main burner gas flow even during a power outage.

Important Technical Specifications:

The V800 family is available in 7 capacity ratings.

- Capacity Ratings:

- 110 cfh [3.1 m³/hr] series for heating appliances.

- 180 cfh [5.1 m³/hr] to 600 cfh [17 m³/hr] series for central heating.

- Pipe Sizes:

- 1/2 x 3/8: 110 cfh (3.1 m³/hr)

- 1/2 x 1/2: 225 cfh (5.1 m³/hr)

- 1/2 x 3/4: 250 cfh (5.8 m³/hr)

- 3/4 x 3/4: 335 cfh (5.9 m³/hr)

- 3/4 x 3/4: 450 cfh (12.7 m³/hr) (High Capacity)

- 3/4 x 1: 503 cfh (14.2 m³/hr) (High Capacity)

- 1 x 1: 600 cfh (17.0 m³/hr) (High Capacity)

- Pressure Rating: A.G.A. rating 1/2 psi [3.5 kPa] inlet pressure. Designed for safe operation up to 28 in. wc [7.0 kPa].

- Mounting: All models can be mounted from 0 to 90 degrees from the vertical position of the gas control knob.

- Pressure Tapping: Taps are 1/8 in. NPT with plug, outlet tap standard, inlet tap available (specify when ordering).

- Electrical Connections:

- 100V, 120V, and 220/240V valve operators use 36 in. [0.9 mm] leadwires (2).

- 24V and Powerpile valve operators use combination screw and quick-connect (1/4 in. male) terminals.

- Thermostat Heat Anticipator Setting: 24V Models: 0.2A. 100V, 120V, 220/240V, Powerpile Models: Not applicable.

- Pilot Gas Outlet: Compression fitting for 1/4 in. OD tubing.

- Ambient Temperature Range:

- Suffix A, C, H: 32° F to 175° F [0° C to 79° C].

- Suffix M, P: -40° F to 175° F [-40° C to 79° C].

- Pressure Regulator Type: Standard (V5306) and Step-opening (V5307).

- Factory Set Outlet Pressure:

- Natural Gas (Nat.): Standard 3.5 in. wc (0.9 kPa); Step-opening 0.9 in. wc (0.2 kPa) step, 3.5 in. wc (0.9 kPa) full rate.

- LP Gas: Standard 11.0 in. wc (2.7 kPa); Step-opening 2.2 in. wc (0.5 kPa) step, 11.0 in. wc (2.7 kPa) full rate.

- Thermocouple Requirement (for 24V, 100V, 120V, 220/240V models): Q309 or Q340 suggested. Nominal output: 30 mV, 0.02 ohms. Open circuit turndown voltage: 2mV.

- Powerpile Generator Requirement (for 750 mV models): Q302 or Q313 suggested. Nominal output: 750 mV, 3.4 ohms. Open circuit turndown voltage: 141 mV.

- Approvals: American Gas Association Design Certificate: P-G-774A. Underwriters Laboratories Inc. Component Recognized: File No. MH5323, Guide No. MCCZ2. DIN Approval: No. 76.01c.050 (V400C5011 only).

Usage Features:

- Super Tradeline Models: Offer additional features not available on Tradeline or standard models, designed to replace a wide range of Honeywell and competitive controls. These include left and right side outlets in addition to the straight-through outlet, an ambient temperature range of 32° F to 175° F [0° C to 79° C], and reducer fittings to fit various sizes. They come in a TRADELINE pack with a cross-reference label and special instruction sheet.

- Tradelinе Models: Selected and packaged for ease of stocking, handling, and maximum replacement value. Specifications are similar to standard models unless noted. They also include left and right side outlets and reducer fittings.

- Standard Models: Basic models with magnetic type or Powerpile operators.

- Installation: Requires careful reading of instructions, verification of product suitability for the application, and installation by a trained, experienced service technician. Gas supply must be turned off before installation, and a gas leak test performed afterward. A sediment trap must be installed in the gas supply line. Pipe compound should be applied moderately, leaving two end threads bare, and LP installations require LP-resistant compound.

- Pilot Lighting: Involves turning the gas control knob to OFF, waiting five minutes, then turning to PILOT, depressing the knob, and lighting the pilot burner. The knob must be held for about one minute until the pilot remains lit.

- Pilot Flame Adjustment: The pilot flame should envelop 3/8 to 1/2 in. [10 to 13 mm] of the thermocouple or generator tip. Adjustment is made via a screw beneath a cover, which must be replaced and tightened firmly after adjustment.

- Main Burner Adjustment: Gas input to the main burner must be checked and adjusted according to appliance nameplate ratings, ensuring proper primary air supply for complete combustion. This can be done by clocking the gas meter or using a manometer to check outlet pressure. Pressure regulators can be adjusted using a screwdriver after removing the adjustment cap.

- Safety Shutdown Performance: Regular checks are required to ensure the main burner goes off and the pilot remains lit when the knob is in PILOT position. If the pilot flame is extinguished, gas flow should stop within 2-1/2 minutes.

Maintenance Features:

- Regular Preventive Maintenance: Crucial for applications with heavy loads on system controls, such as commercial cooking, agricultural, and industrial settings, where equipment may operate 100,000-200,000 cycles per year.

- Maintenance Program: Should include regular checkout of the gas control as outlined in the startup and checkout procedures, and as described in the appliance manufacturer's literature.

- Maintenance Frequency: Determined by application-specific factors:

- Cycling Frequency: Appliances cycling 100,000 times annually should be checked monthly.

- Intermittent Use: Seasonally used appliances should be checked before shutdown and again before the next use.

- Consequence of Unexpected Shutdown: Systems where an unexpected shutdown would be costly should be checked more often.

- Dusty, Wet, or Corrosive Environment: Systems in such environments should be checked more often due to accelerated deterioration.

- Replacement Criteria: The gas control should be replaced if:

- It does not perform properly during checkout or troubleshooting.

- The gas control knob is hard to turn or push down, or fails to pop back up when released.

- The control is likely to have operated for more than 200,000 cycles.

- It has been flooded with water.

- There is any physical damage, tampering, bent terminals, missing or broken parts, stripped threads, or evidence of exposure to heat.

- Gas Leak Test: Must be performed any time work is done on a gas module. Connections should be painted with a rich soap and water solution; bubbles indicate a leak. If a leak is detected, connections must be tightened or parts replaced.

Loading...

Loading...