Do you have a question about the Honeywell XNX-BTAE Series and is the answer not in the manual?

| Model | XNX-BTAE Series |

|---|---|

| Type | Transmitter |

| Output Signal | 4-20 mA, HART |

| Display | LCD |

| Enclosure Rating | IP66 |

| Enclosure Material | Aluminum or stainless steel |

| Certifications | ATEX, IECEx, CSA |

| Communication | HART |

| Mounting | Wall, pipe |

| Operating Humidity | 0 to 100% RH (non-condensing) |

Identifies hazardous or unsafe practices that could result in severe injury or death.

Details requirements for safe installation in hazardous locations, including conduit and grounding.

Outlines specific conditions and parameters for safe operation in potentially hazardous environments.

Explains the 4-20mA output with HART communication capabilities for configuration and status.

Lists UL, CSA, FM, ATEX, and INMETRO certifications for various XNX transmitter versions.

Explains the external access to the HART interface for programming and configuration via an IS barrier.

Explains the kit for mounting EC sensors remotely via an IS cable.

Explains how to use magnetic switches to enter menus, reset alarms/faults, and adjust settings.

Lists user actions from the Main Menu, including testing and configuration.

Lists options within Test Mode, including Inhibit, Force mA Output, and Alarm/Fault Simulation.

Outlines the calibration options, including Gas Calibration, Bump Test, and mA Output Calibration.

Details the extensive options available in Configuration Mode, from language to security settings.

Provides warnings and cautions for sensor placement and factors to consider.

Describes various mounting methods for the transmitter, including wall and pipe mounting.

Explains the wiring process, personalities, terminal blocks, and POD.

Discusses wiring-induced voltage drops, electrical noise, and grounding.

Guides the selection of appropriate power supplies based on voltage and power requirements.

Explains how to configure the 4-20mA output (Sink, Source, Isolated) and power connections.

Describes terminal block usage, wire gauge, stripping, and tightening specifications.

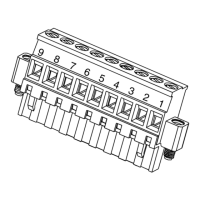

Illustrates EC personality board terminal blocks, jumper switches, and assignments.

Provides a step-by-step guide for installing EC sensors, including cautions.

Details the procedure for mounting EC sensors remotely using a mounting kit.

Explains wiring connections for mV personality boards, including sensor type tables.

Guides the remote mounting of sensors for mV personality configurations, including junction box requirements.

Describes RS-485 digital communication for IR sensors and local programming options.

Describes the initial power-up and boot-up procedure for various sensor types.

Explains functions and security levels required for configuration menu items.

Explains how to set the identity of the mV sensor attached to the transmitter.

Explains how to set the target gas for sensors capable of detecting multiple gases.

Explains setting the full-scale range and alarm direction/limits.

Allows selection of mA output levels for inhibit, fault, overrange, beam block, and low signal.

Loads default parameters for calibration and sensor life when replacing sensors.

Sets or resets level 1 and level 2 passcodes for configuration menu access.

Prevents alarms from being triggered during testing or maintenance.

Allows testing of peripheral devices by forcing mA output values.

Allows testing of peripheral devices driven by relays from the transmitter.

Simulates alarms or faults to test transmitter and peripheral safety devices.

Lists the icons and functions available in the Test Menu for verification.

Displays the currently configured alarm information, including range and alarm limits.

Shows current values for mA output for inhibit, warning, and overrange.

Provides access to Zero and Span calibration, and bump testing.

Details the procedure for zero and span calibration of EC/mV sensors and Searchpoint Optima.

Outlines the steps for calibrating the transmitter's attached sensors.

Explains the process of performing a zero calibration for sensors.

Details the procedure for performing a span calibration using calibration gas.

Provides calibration procedures and cautions for EC sensors, including Hydrogen Sulfide.

Describes the procedure for zero and span calibration of MPD flammable sensors.

Explains the importance and procedure for functional gas testing (bump testing) of sensors.

Adjusts the milliamp output to provide correct levels at peripheral devices.

Provides a step-by-step guide for replacing MPD sensor cartridges.

Details the process for replacing EC sensor cartridges and cells.

Details electrical, power consumption, termination, signal, cable, and construction specifications.

Lists hazardous area approvals (UL, CSA, FM, ATEX, etc.) by part number series.

Details gas detection performance, accuracy, response times, and operating temperatures.

Detailed table of certifications for various XNX models and options.

Explains calibration menus for zero/span calibration, bump testing, and optical alignment.