Howden 24-07.030r04 13/25

E-series Axial Flow Cooling Fans

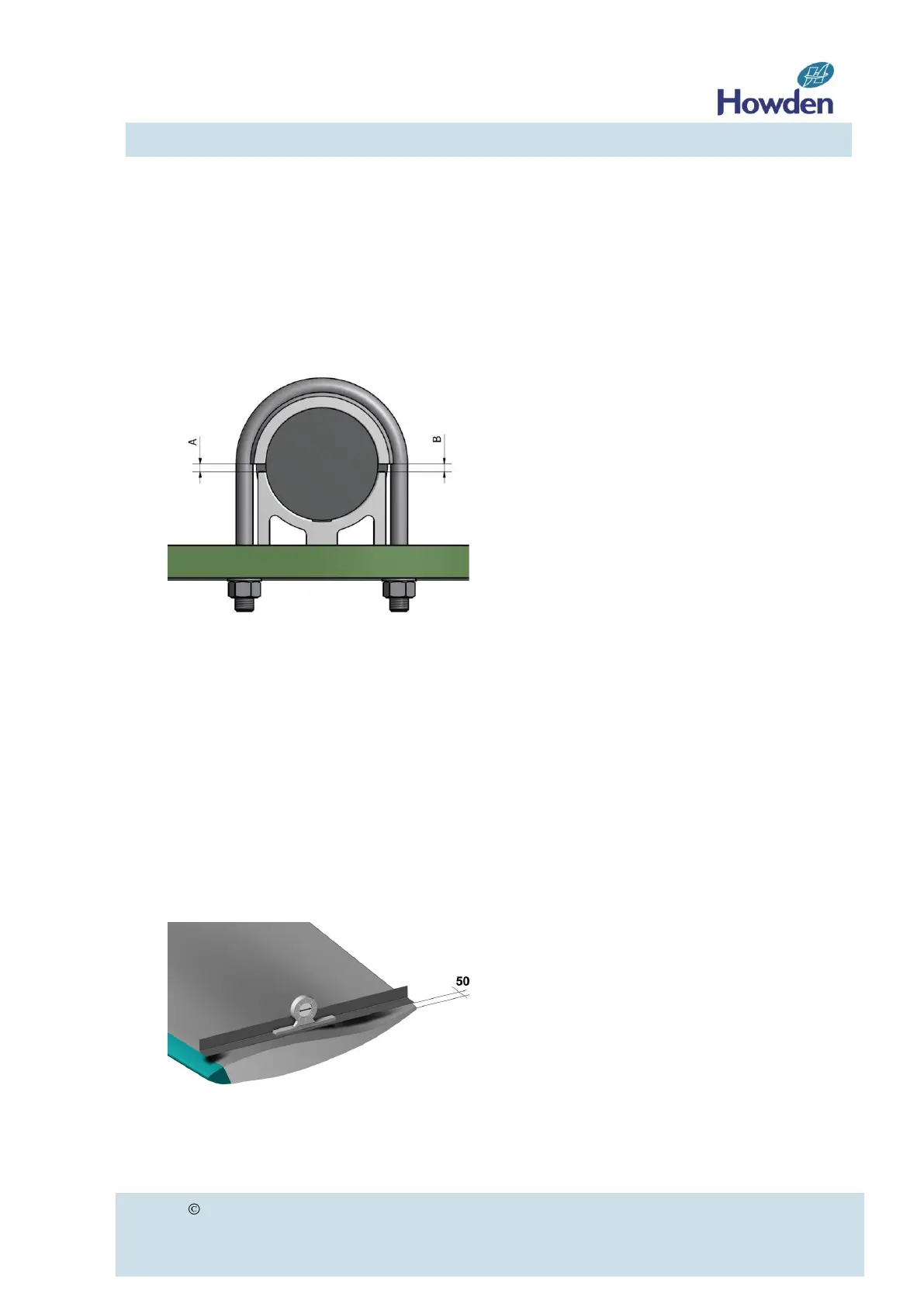

serting the outer U-bolt first. Check if the

upper clamping piece is mounted

horizontally by measuring the gap A an B

between the lower and upper clamping

piece (see figure 14).

Figure 14

c. Tighten the nuts alternating such that the

blade can still be somewhat turned in the

clamping piece.

d. Make sure that the blade stem collar is flush

against the lower clamping piece, which can

be achieved by pulling the blade outwards.

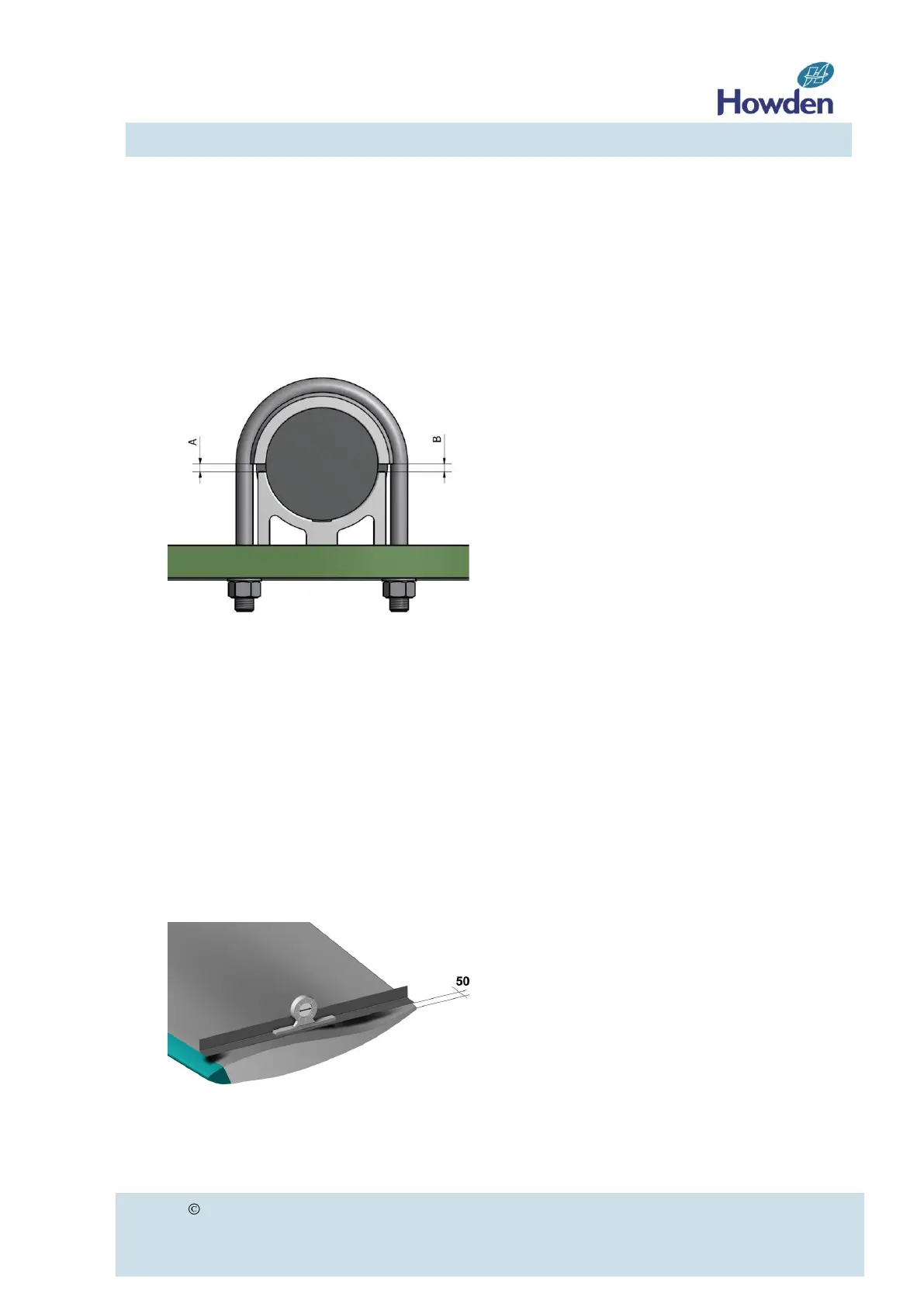

e. Place a straight edge or a sufficiently stiff

strip (at least as long as the profile width) on

top of the blade (discharge side) at about 50

mm (2 inches) from the blade profile end.

Place an inclinometer on top of the straight

edge (figure 15).

Figure 15

f. Lift the blade at the tip and rotate the blade

around its axis until the desired angle is set,

within a maximum tolerance of ± 0.5 de-

grees.

g. Re-check if the blade stem collar is flush

against the lower clamping piece.

Tighten the U-bolt nuts evenly to full torque

as shown in figure 16, starting with the U-

bolt at the collar side. Both the torque

values of our standard stainless steel (A2)

or galvanised steel (ST8.8) hardware as

well as our optional A4 stainless steel

hardware are shown. The material code A2,

St8.8 or A4 is stated on the nut. Make sure

that the blade angle does not change during

this operation (for the correct thread size

refer to table 8 on page 23).

After tightening of the nuts, the threaded

bolt ends out of the nuts shall have equal

length. The U-bolt is damaged if this is not

the case and don't fit for purpose anymore.

Loading...

Loading...