Howden 24-07.030r04 14/25

E-series Axial Flow Cooling Fans

Note: the polyester stem will be com-

pressed during this operation and may pro-

duce a cracking sound.

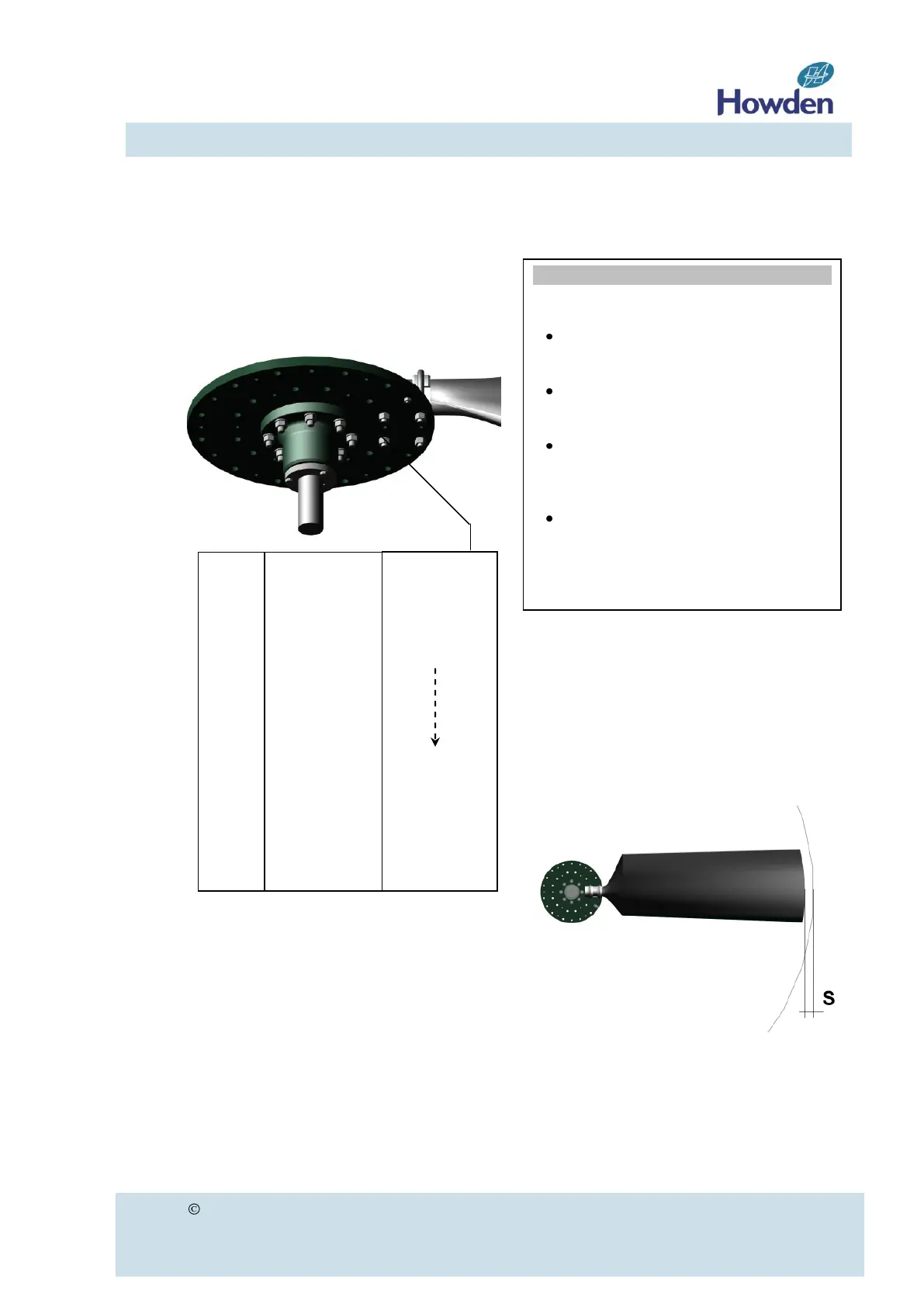

Figure 16

h. Repeat the above operation for all blades.

i. Re-tighten the U-bolts after 50-75 hours in

operation, or 120-150 hours stand still. Do

not loosen the nuts first, but start to tighten

immediately.

j. When the blade angle has changed, the U-

bolts need to be tightened again to full

torque and also re-tightened after 120-150

hours.

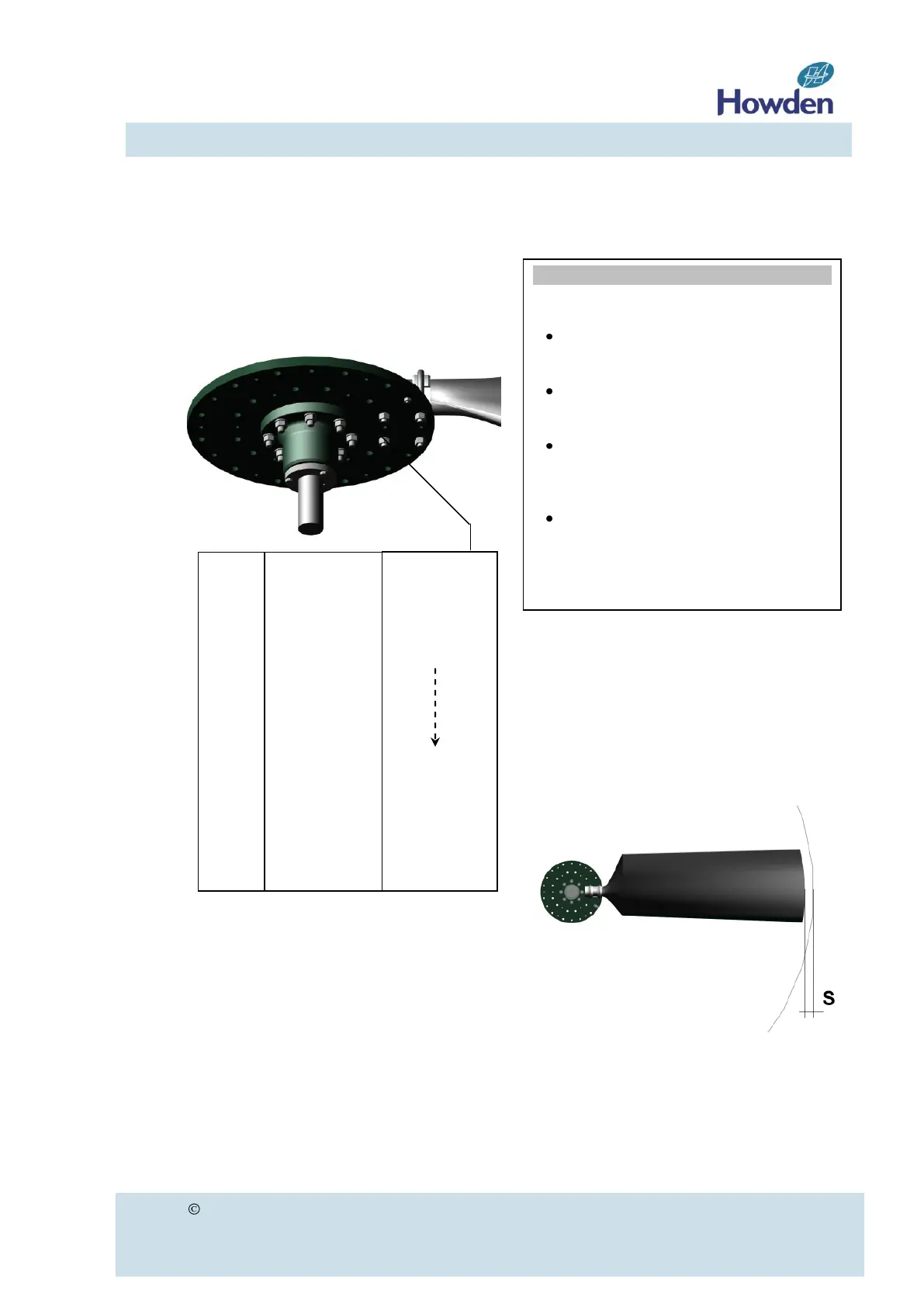

Minimum tip-clearance

Tip clearance “s” is the distance between the

blade tip and the impeller casing (figure 17).

Due to normal impeller casing tolerances the

tip clearance is not constant around the im-

peller casing.

Figure 17

Howden recommends a tip clearance of 0.5% of

the impeller diameter. Fan selections using

Howden CF-P20 software use this default stan-

dard, unless otherwise specified. Tip clearance

shall never be less than 0.25%.

WARNING

DO NOT forget to re-tighten the U-

bolts as they may loosen due to creep

of the FRP material of the blade stem.

ONLY use original Howden hardware.

The nuts are treated with special “low

friction” coating.

DO NOT re-tighten location bolts of

the lower clamping pieces (location

bolts are used in special applications

only).

After loosening and disassembling of

a U-bolt, the legs of the U-bolt have

lost the parallel shape due to

relaxation effects. That is why it is not

allowed to re-use those U-bolts.

Thread

size

M12

M16

M20

M24

M30

M36

M42

(A2, St8.8)

= Standard

Nm lb

.

ft

60 44

140 103

250 184

425 313

650 479

1100 811

1300 959

( A4)

= Optional

Nm lb

.

ft

Idem

380 280

500 369

970 715

- -

Loading...

Loading...