Howden 24-07.030r04 9/25

E-series Axial Flow Cooling Fans

Coupling flange with parallel bore

a) Check if the shaft and bore diameters are

according to specification. The standard

execution has a H7 fit.

b) Slightly lubricate the shaft, the key, and

the bore of the hub with grease.

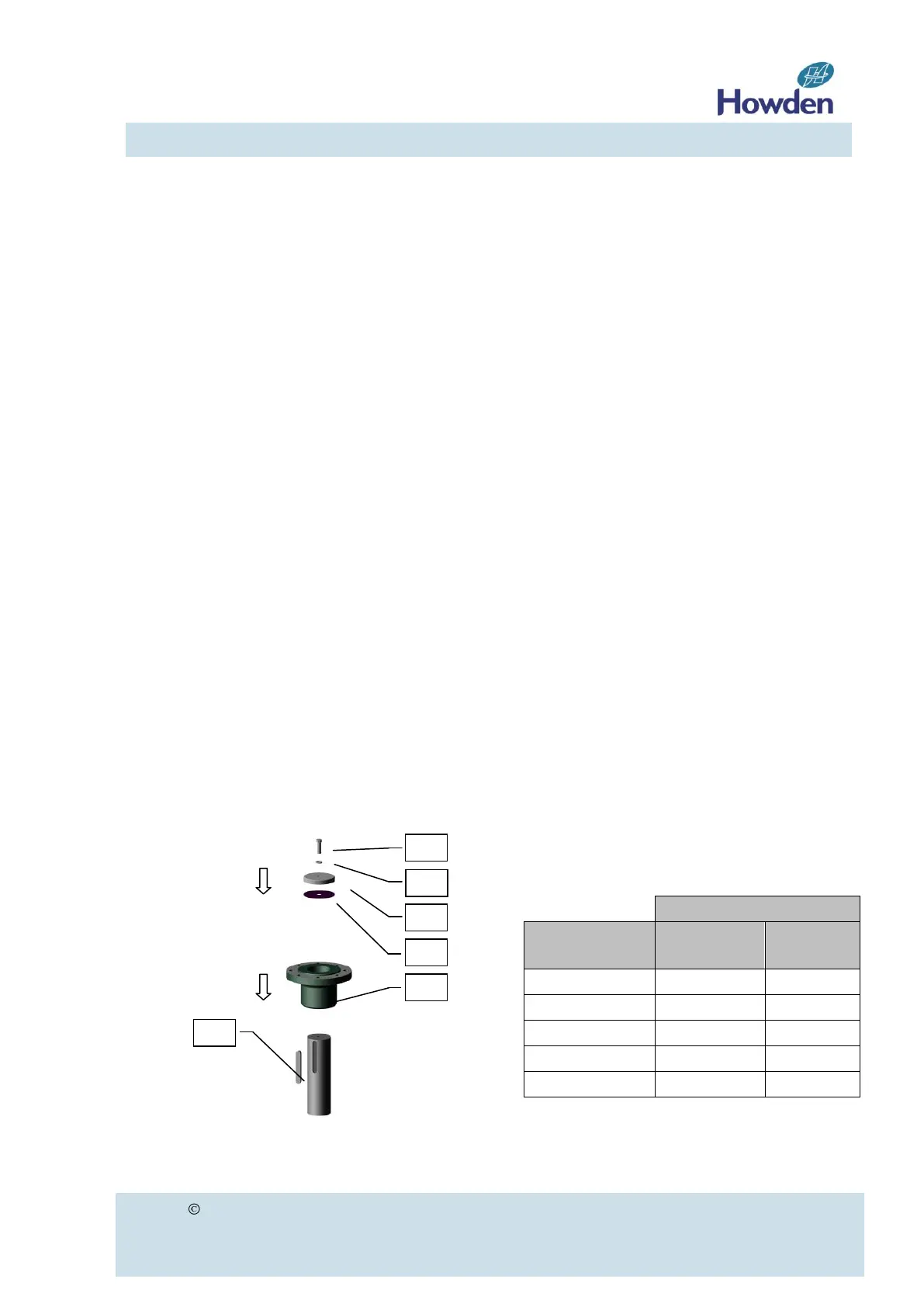

c) Locate the key (19) into the drive shaft

(figure 7).

d) To slip the coupling flange over the shaft

we advise you to uniformly heat up the

coupling flange up to maximum 120 °C

(248 °F) by means of a hot plate, electric

induction or oil bath, until a 0.15mm dif-

ference in diameter is reached. Wear

protective gloves during this operation.

e) Slip the coupling flange (11) onto the

drive shaft and check the key for proper

fit. Be sure the coupling flange is com-

pletely through the shaft against the shaft

shoulder.

f) For reverse coupling flange configuration:

(e.g. impeller hanging below the driver)

Install the retaining plate (14) with gasket

(17) and secure it to the shaft with the

lock washer (16) and the central bolt

(15). Supply of retaining plate items 14,

15, 16 and 17 by Howden is optional.

Item 19 (key) is not supplied by Howden.

For torque values of the retaining plate

bolts see table 7 on page 22.

Figure 7

Coupling flange with tapered bushing

(Supply of coupling flange with tapered

bushing is optional).

a) Do not lubricate bushing, coupling flange

bore or hardware. Use of lubricants can

cause coupling flange damage.

b) Slip the bushing onto the drive shaft and

check the key (19) for proper fit (figure 8

on page 10). Be sure the shaft is com-

pletely through the bushing. Keep a bolt

length as minimum distance X between

bolts (13) and flange of the drive (figure 9

on page 10).

c) Lock the bushing on the shaft by tighten-

ing the setscrew in the flange. Support

the bushing with a sleeve to prevent it

from sliding down during assembly.

d) Install the coupling flange onto the bush-

ing. Start bolts (13) by hand turning just

enough to engage threads.

e) Keep tightening them as equally as

possible, in several steps, while drawing

the hub onto the bushing until the bush-

ing tightly grips the shaft.

f) Tighten the bolts to the torque shown in

table 3. Do not over-torque. Excessive

torque can cause coupling flange or

bushing damage. Some gap must remain

between the flange of the bushing and

coupling flange in properly tightened as-

sembly.

Torque value for bolts

tapered bushing to coupling flange

Table 3

Loading...

Loading...