Model

5254C

Section

V

SECTION V

MAINTENANCE

5-1.

INTRODUCTION.

5-2.

This section

provides

maintenance and

service

information

for the Model 5254C Frequency Converter.

Included

are a periodic maintenance procedure, a

table

of

recommended test equipment, an

in-cabinet

performance check

which may be used to

verify

proper

operation of the frequency converter, troubleshooting

procedure, and

repair

and adjustment

procedure.

5-3.

PERIODIC

MAINTENANCE.

5-4.

No special maintenance

procedures are required

when the converter

is

operated in normal environments.

However, if unit

is

subjected to

operation in extremely

dusty environments, periodically clean all

gears

with

a

lint-free

cloth and apply a coating of light, petroleum

base,

open-gear

grease

to

all

gear teeth.

5-5.

TEST

EQUIPMENT.

5-6.

Recommended

test

equipment for performance

checking,

troubleshooting

and circuit adjustment after

repair

is listed

in

Table

5-1.

Other

test

instruments

may be used if their

specifications

equal or exceed

the required

characteristics.

5-7.

IN-CABINET PERFORMANCE CHECK.

5-8.

The following

performance check

(Table

5-4)

verifies proper

operation of

all circuits in the

Model

5254C

and may be

used:

a.

as

part of an incoming inspection

check of instru-

ment specifications;

b. periodically,

for

instruments used

in

systems

where maximum reliability is

of

utmost

importance;

c. as part of a

troubleshooting

procedure to

locate

malfunctioning circuits,

and

d. after any

repairs or

adjustments,

before return-

ing instrument to

regular

service.

5-9.

TROUBLESHOOTING.

5-10. Refer

to

Section

IV, Principles of Operation,

for information on

the

operation

of

circuits. Table

5-2

gives

the reference designations

of assemblies used

in the converter and their corresponding

nomenclatures.

Figure

5-2

shows

the location of all assemblies used

in the

Model

5254C.

Figures

8-2

and

8-3

show com-

ponent

location on the

assemblies.

Table

8-1,

Trouble-

shooting

Aids,

gives

information

on

waveforms and

dc voltages which are

present when circuits

are

oper-

ating properly.

The waveforms are referenced to test

points

throughout the converter.

These

test points

are keyed to the schematic diagrams,

Figures

8-2

and

8-3.

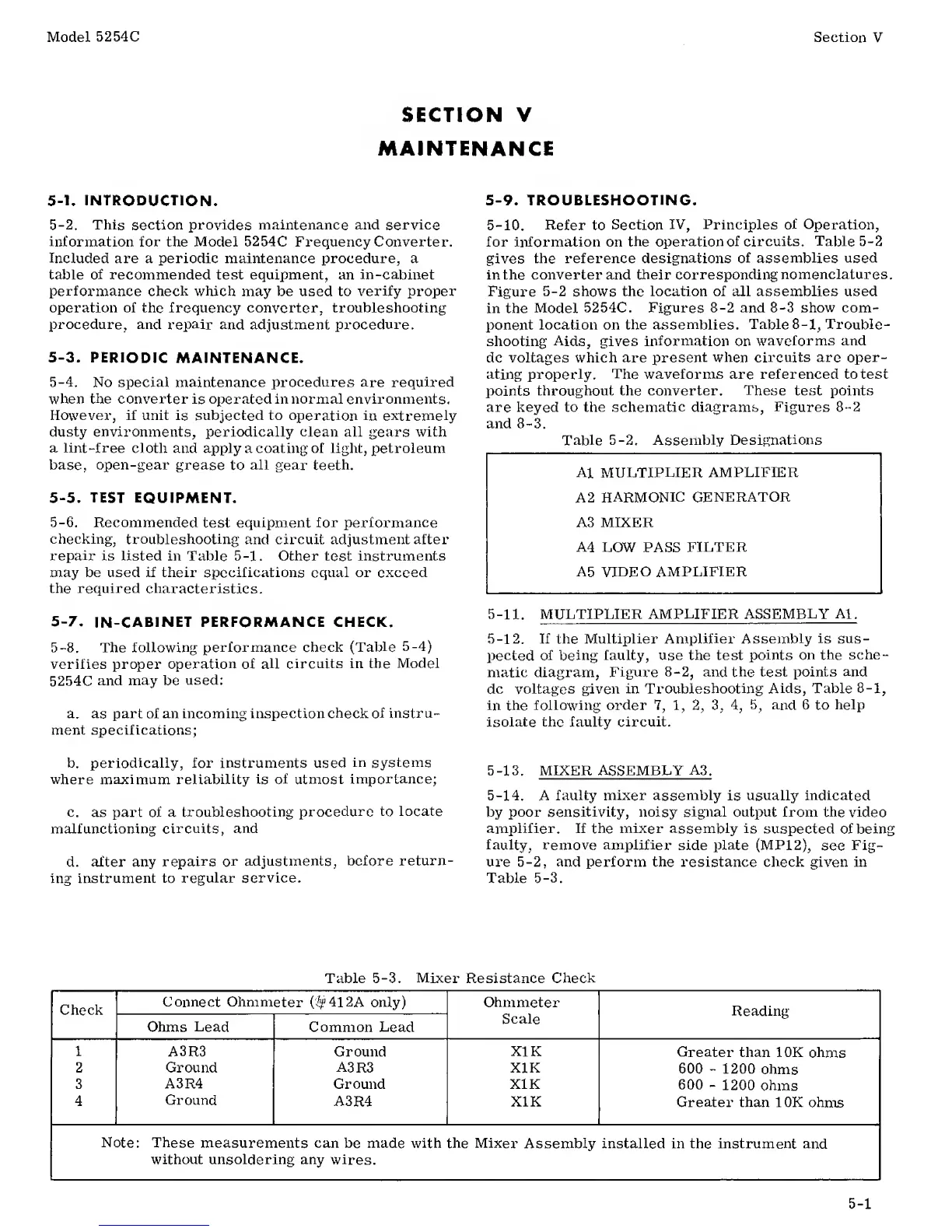

Table

5-2.

Assembly

Designations

A1

MULTIPLIER

AMPLIFIER

A

2

HARMONIC

GENERATOR

A3 MIXER

A4

LOW

PASS

FILTER

A5

VIDEO

AMPLIFIER

5-11.

MULTIPLIER AMPLIFIER

ASSEMBLY Al.

5-12.

If

the

Multiplier

Amplifier Assembly is sus-

pected of being

faulty, use the test

points

on

the

sche-

matic diagram,

Figure

8-2,

and

the

test points and

dc

voltages given in

Troubleshooting Aids,

Table

8-1,

in the

following order

7, 1, 2, 3, 4, 5,

and 6 to

help

isolate the faulty circuit.

5-13.

MIXER ASSEMBLY

A3,

5-14.

A

faulty mixer assembly

is

usually indicated

by

poor sensitivity, noisy signal

output

from

the video

amplifier. If

the

mixer

assembly is

suspected of being

faulty, remove amplifier

side

plate

(MP12),

see

Fig-

ure 5-2, and perform the resistance

check

given

in

Table

5-3.

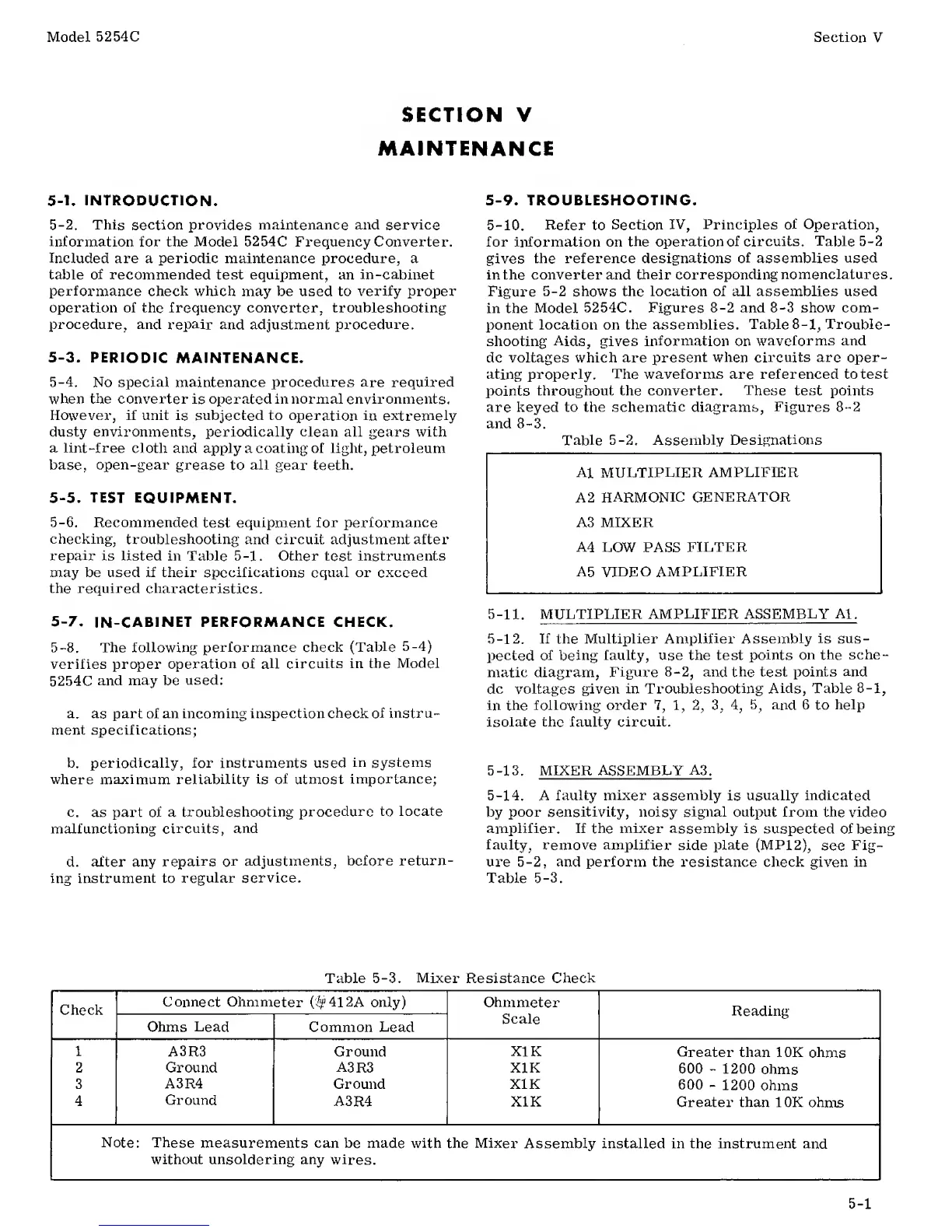

Table

5-3.

Mixer

Resistance

Check

—

Check

Connect Ohmmeter

(fy

41

2A

only) Ohmmeter

Scale

Reading

Ohms

Lead

Common

Lead

i

A3R3

Ground

XI

K

Greater

than 10K

ohms

2

Ground

A3R3

X1K

600

-

1200

ohms

3 A3R4

Ground

XI

K

600

-

1200

ohms

4

Ground

A3R4

X1K

Greater

than 10K

ohms

Note: These

measurements

can

be

made

with the

Mixer

Assembly installed in the

instrument and

without

unsoldering any

wires.

5-1

Loading...

Loading...