14 Printer systems

Printer systems

the substrate, and communicate any small adjustments required by the system to move the substrate

smoothly.

The window of the OMAS sensor must be cleaned of dust and ink to functioning correctly. The cleaning

procedure for this is described in the customer document ‘Maintenance and Troubleshooting guide’, in

the section called ‘Clean the substrate advance sensor window’.

During the substrate load, the printer detects that the substrate has

reached the print platen when the OMAS captures its image.

TOMAS

To compensate for temperature changes and mechanical expansion,

OMAS receives a temperature reading from TOMAS sensor.

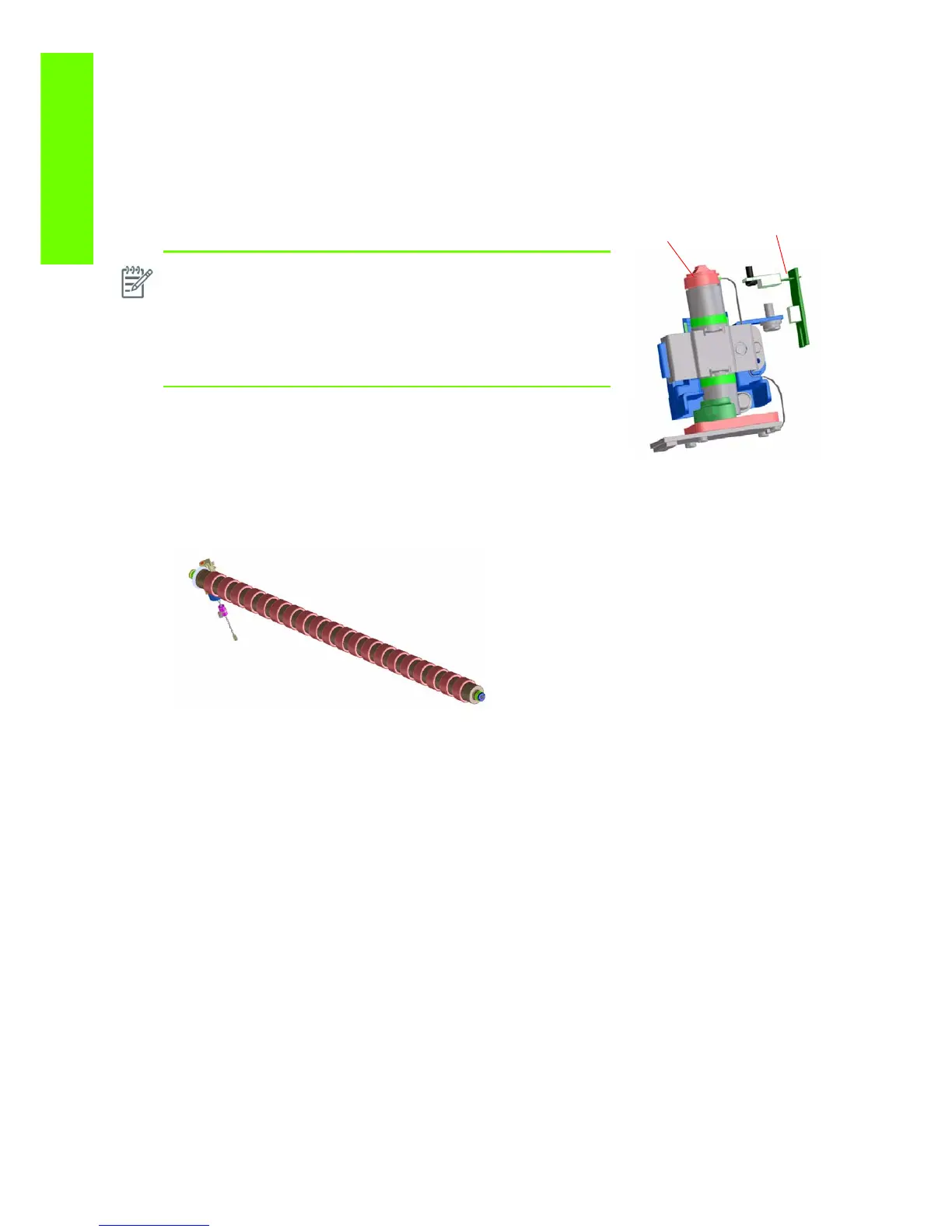

Drive roller and motor

The drive roller and motor advance the substrate through the substrate path. The motor requires 24 V, and

is controlled by the Printmech PCA.

Drive Roller Encoder Disc and Encoder PCA

The Drive Roller Encoder Disc and Encoder PCA provide the feedback system for the Drive Roller.

• The Encoder disc is a round disc mounted to the left end of the Drive Roller.

• The Encoder PCA is mounted with a sensor that reads the encoder movements of the disc (the disc

turns with the drive roller).

Pinchwheels

The pinchwheels press the substrate against the Drive Roller to make sure that the Drive Roller can advance

the substrate correctly.

• The pinchwheels are activated with the blue lever at the right side of the media roll and usually do

not have to be lifted unless to correct skew during substrate load or to clear jams.

• The pinchwheel system has a sensor that detects if the system is up or down.

Vacuum Pump, Vacuum Tube Assembly, Vacuum Beam

The print zone is the area of the media path where the transmission of ink to the substrate occurs. The

main function of the system can be defined as providing the surface where the media is printed, keeping

it controlled during the process, playing a main roll on the final IQ of the plots and on the operational

reliability of the printer. The subsystem is composed of the print platen assembly (including the overdrive

wheels), which is the physical interface with the substrate, and the vacuum system which is the mechanical

system where the vacuum pressure used to control the media is generated and conduced.

NOTE: The OMAS sensor cannot detect the surface of some

substrates, such as plastic or very dark substrates. In these cases, the

OMAS sensor must be disabled, and instead the printer uses

feedback from the Driver Roller encoder to calculate the substrate

advance. To disable the OMAS sensor, locate the OMAS Sensor

selector from the print options menu of the RIP and set it to OFF. This

can also be done from the Service menu ⇒ Page 189.

Loading...

Loading...