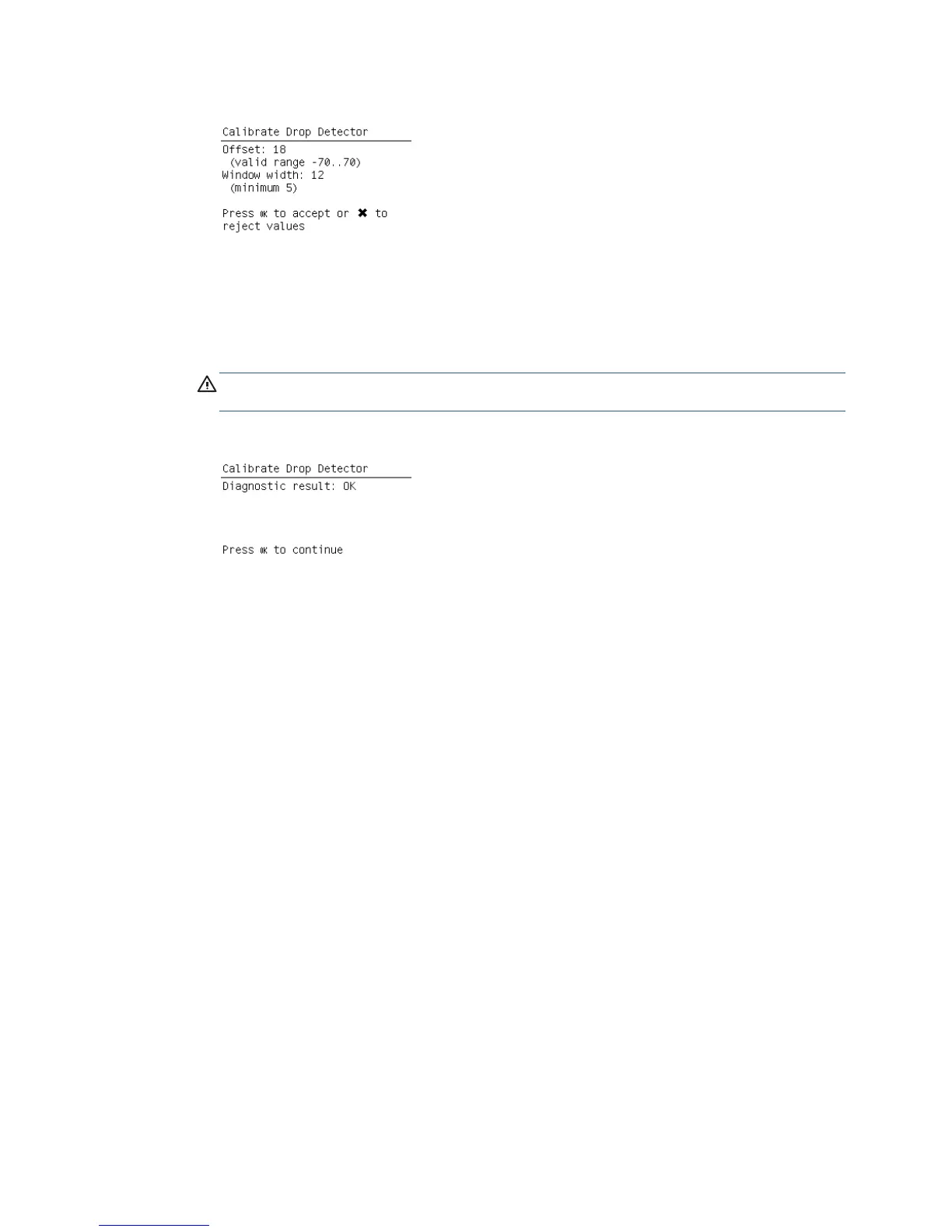

5. Once the Drop Detector has been calibrated, the results are displayed on the front panel.

The offset is the displacement from the nominal Carriage position for drop detection. The window

width refers to values captured by the drop detector sensor. The offset should be within the valid

range, and the window width should be at least the minimum shown. If the values are correct,

press OK to accept them. If not, the Drop Detector is not correctly installed, either because the

Service Station has not been correctly installed in the Scan Axis or because the Drop Detector is

not correctly installed or not working properly. Press Cancel to reject the values.

CAUTION: Do not accept these values if they are not within the right range, as the printer will

not work properly.

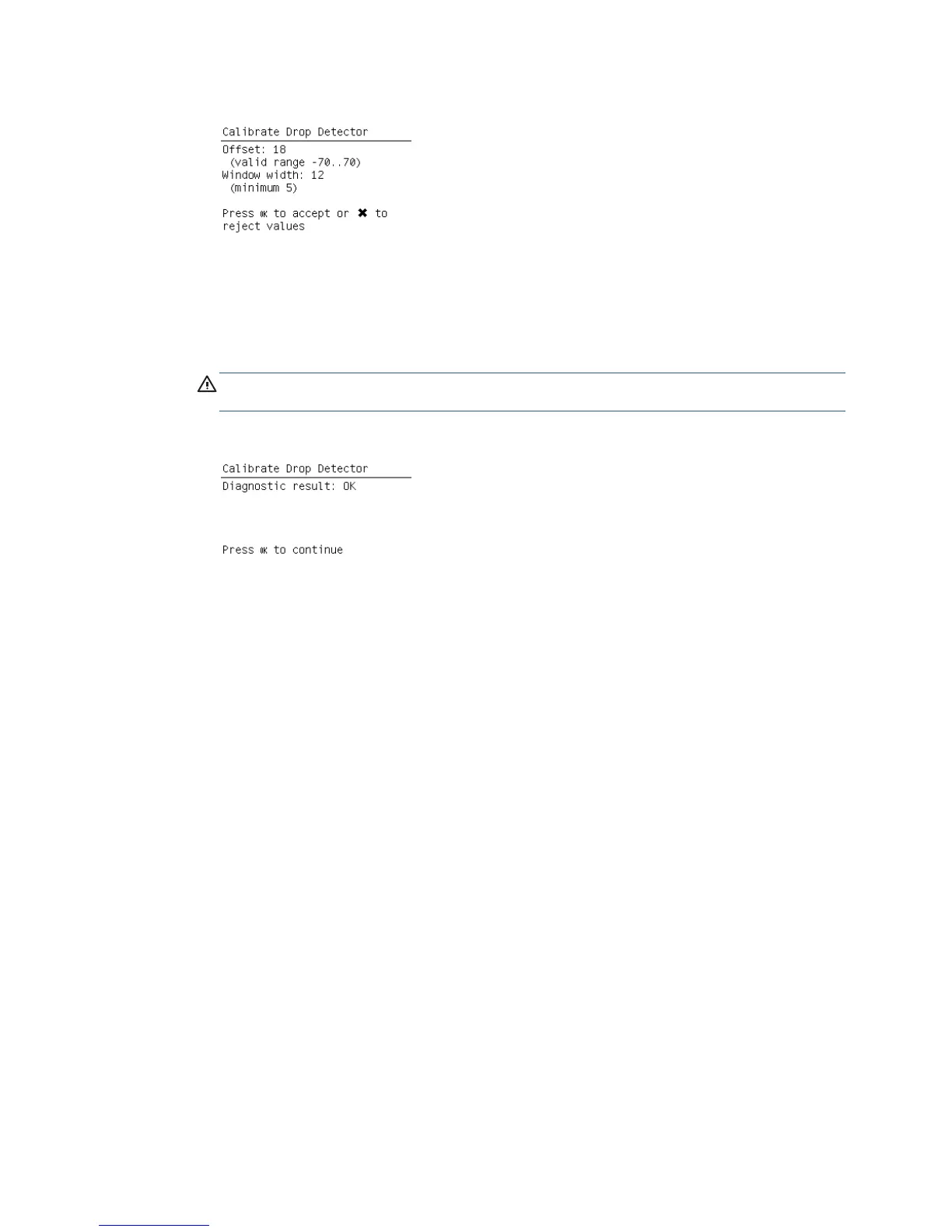

6. Press OK to end the calibration.

Line Sensor calibration

The purpose of this Service Calibration is to calibrate the intensity of the Line Sensor in the Carriage

PCA. An incorrect calibration can result in edge-detection failures during paper loading and incorrect

reading of prints that are used for alignment or calibration.

Perform Line Sensor Calibration whenever:

●

The edge-detect procedure fails during paper loading.

●

The Carriage is disassembled or replaced.

●

The Line Sensor is disassembled or replaced.

●

Banding is detected in prints.

●

Misalignment between colors is detected.

Perform the Line Sensor Calibration as follows:

1. Load the printer with glossy paper at least 36 inches wide, if feasible. If you have difficulty in

loading the paper (which can happen if the Line Sensor is miscalibrated), continue with no paper

loaded.

ENWW

Entering the Service Calibrations menu

129

Loading...

Loading...