The area to check is only the bottom junction pattern for all the colors. The clearest band has to be

around the 0 (±3 dots). Every band is equal to 1 dot error.

In order to solve any problem in the alignment, try the following.

●

Repeat the printhead alignment. You are recommended to use glossy paper, which gives the most

accurate printhead alignment. There are some paper types that are not suitable for Printhead

Alignment (transparent, translucent, …)

●

If the alignment process shows the message Printhead alignment may use up to 3m of

paper in the front panel, it is because the OMAS is not working. This is normal for a few paper

types that cannot be controlled by OMAS. To check whether your paper is OMAS or non-OMAS,

go to the Service Menu, then select Diagnostic print > Others > Visual Media Diagnostic.

●

If the issue cannot be fixed after repeating the printhead alignment, then try to clean the

printheads. To clean the printheads, go to the front panel and select the

icon, then Clean

printheads.

●

If the issue cannot be fixed, then replace the printhead color that is failing in the align check

pattern.

●

If there is an issue in the ThetaZ and it cannot be fixed, check whether the paper works with

OMAS. If so, the issue could be that the OMAS subsystem is malfunctioning. Go to the advance

troubleshooting and apply the OMAS process.

Force drop detection

If the Nozzle Print Test plot has persistent white-point banding in only one color that cannot be fixed

with a printhead recovery, you can use this option to resolve the problem by resetting the nozzle health

database so that all nozzles are assumed to be correct. Once the nozzle health database has been

reset, drop detection is forced.

The normal cause of this white-point banding in a single color is the incorrect detection of failed

nozzles by the drop detector.

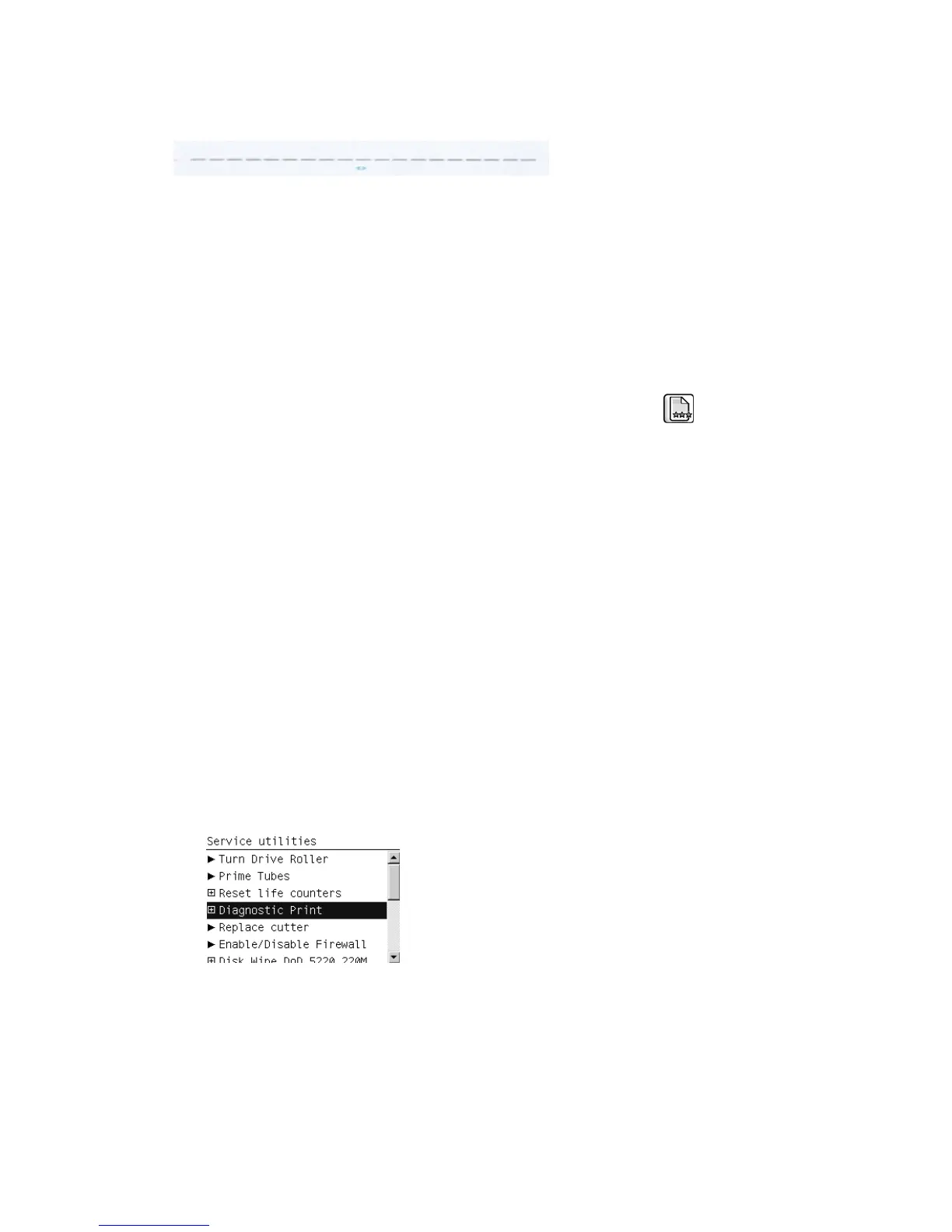

Perform the test as follows.

1. Go to the Service utilities menu and select Diagnostic Print.

160 Chapter 7 Print quality ENWW

Loading...

Loading...