Print quality troubleshooting tools

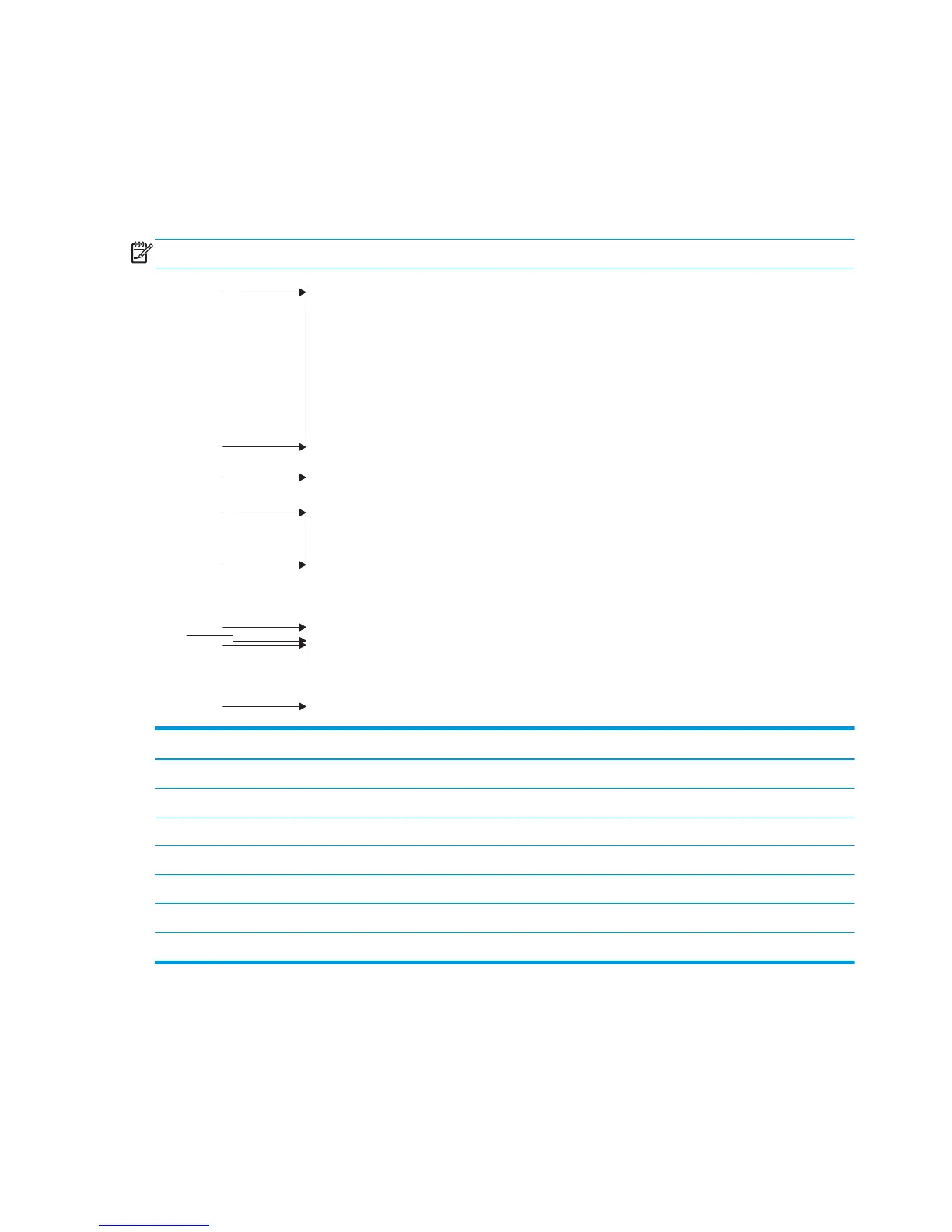

Repetitive image-defect ruler

Use a ruler to measure occurrences of repetitive image defects to help solve image quality problems. Place

the ruler next to the first occurrence of the defect on the page. Find the distance between identical defects

and use the figure below to identify the component that is causing the defect.

NOTE: When printing this defect ruler, verify that any scaling options in the printer driver are disabled.

0 mm

35 mm

42 mm

79 mm

60 mm

94 m m

76 m m

80 mm

50 mm

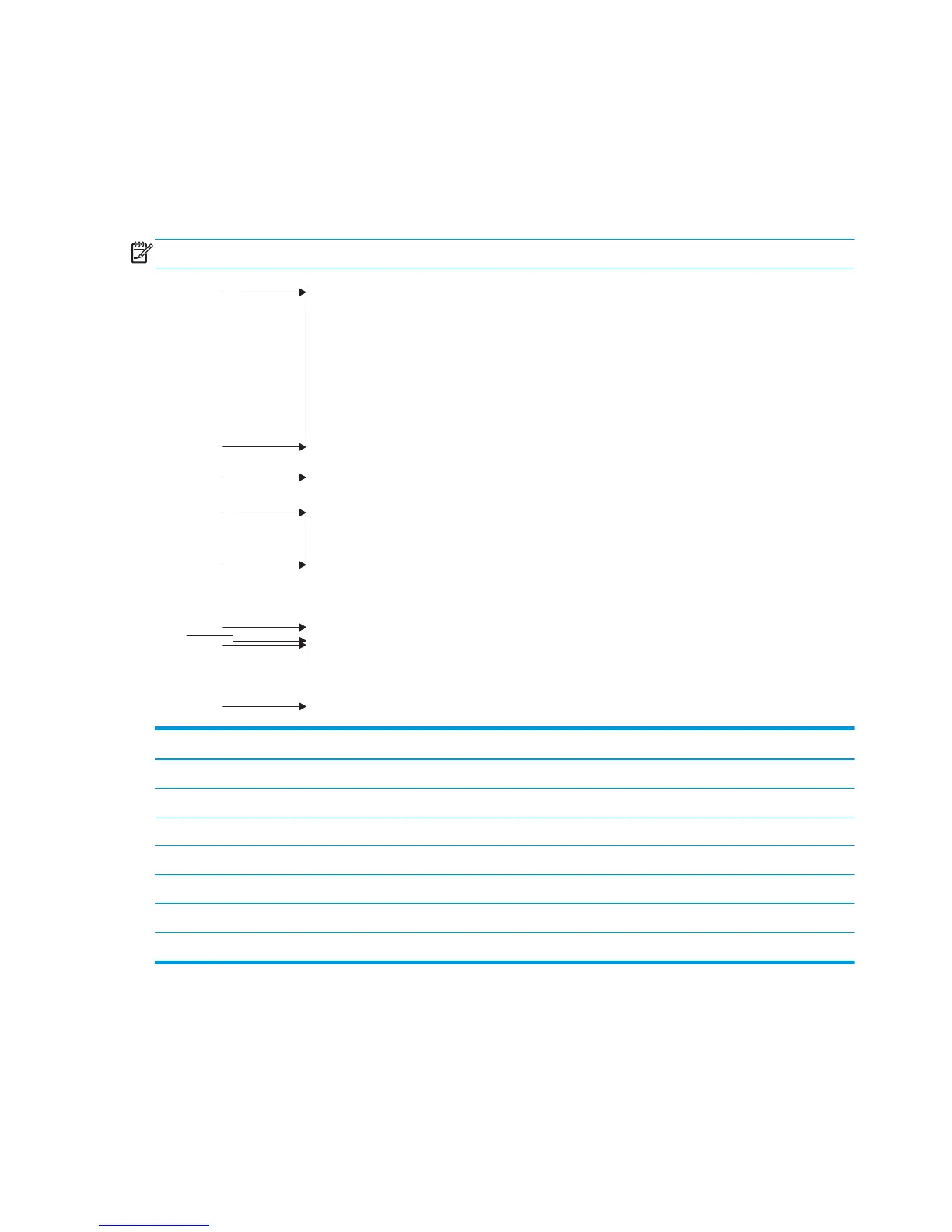

Distance between defects Product components that cause the defect

35 mm Print cartridge (primary charging roller)

42 mm Print cartridge (developer roller)

50 mm Print engine (primary transfer roller)

60 mm Print engine (secondary transfer roller)

76 mm Fuser (fuser film)

79 mm Fuser (pressure roller)

94 mm Print cartridge (OPC)

Calibrate the product

Calibration is a product function that optimizes print quality. If you experience any image-quality problems,

calibrate the product.

344 Chapter 3 Solve problems ENWW

Loading...

Loading...