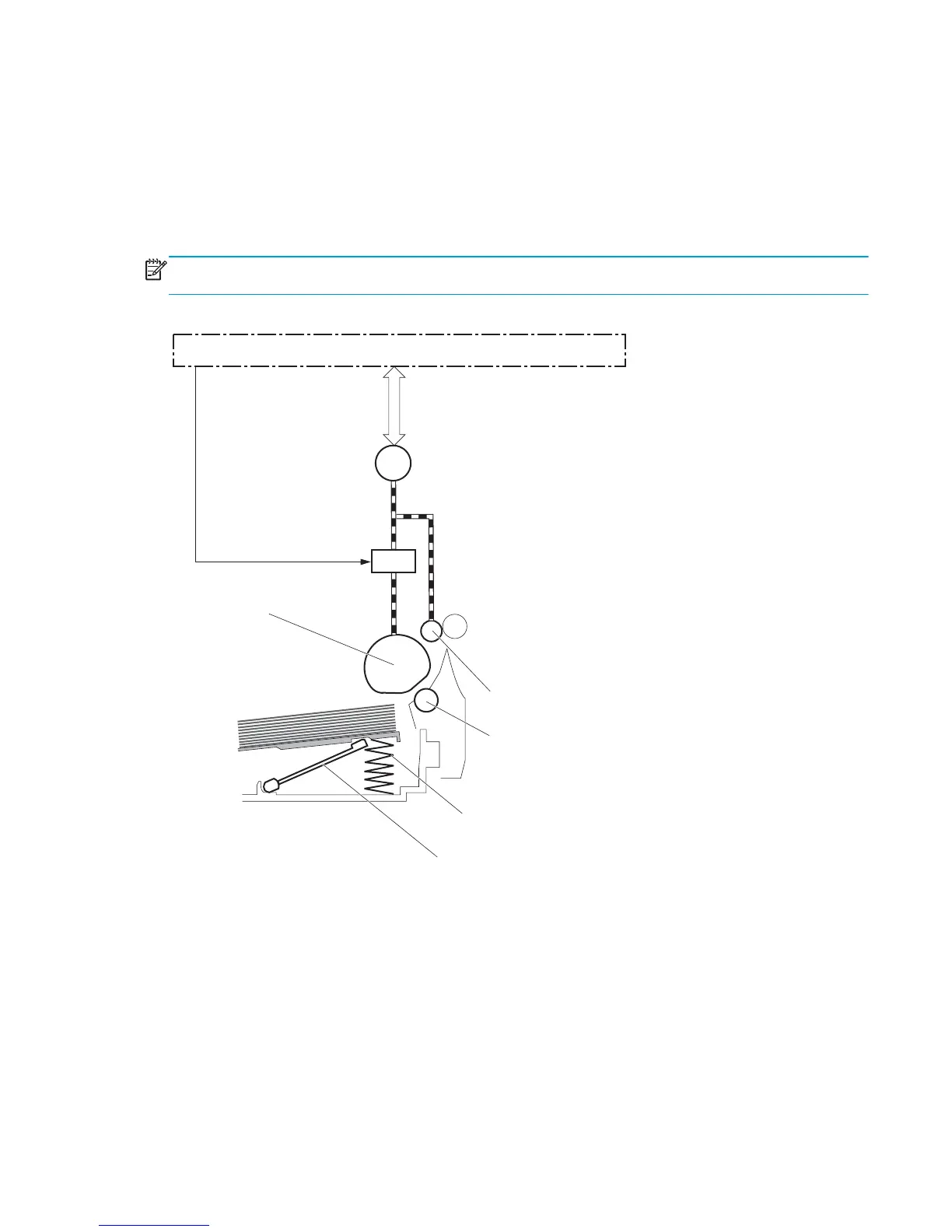

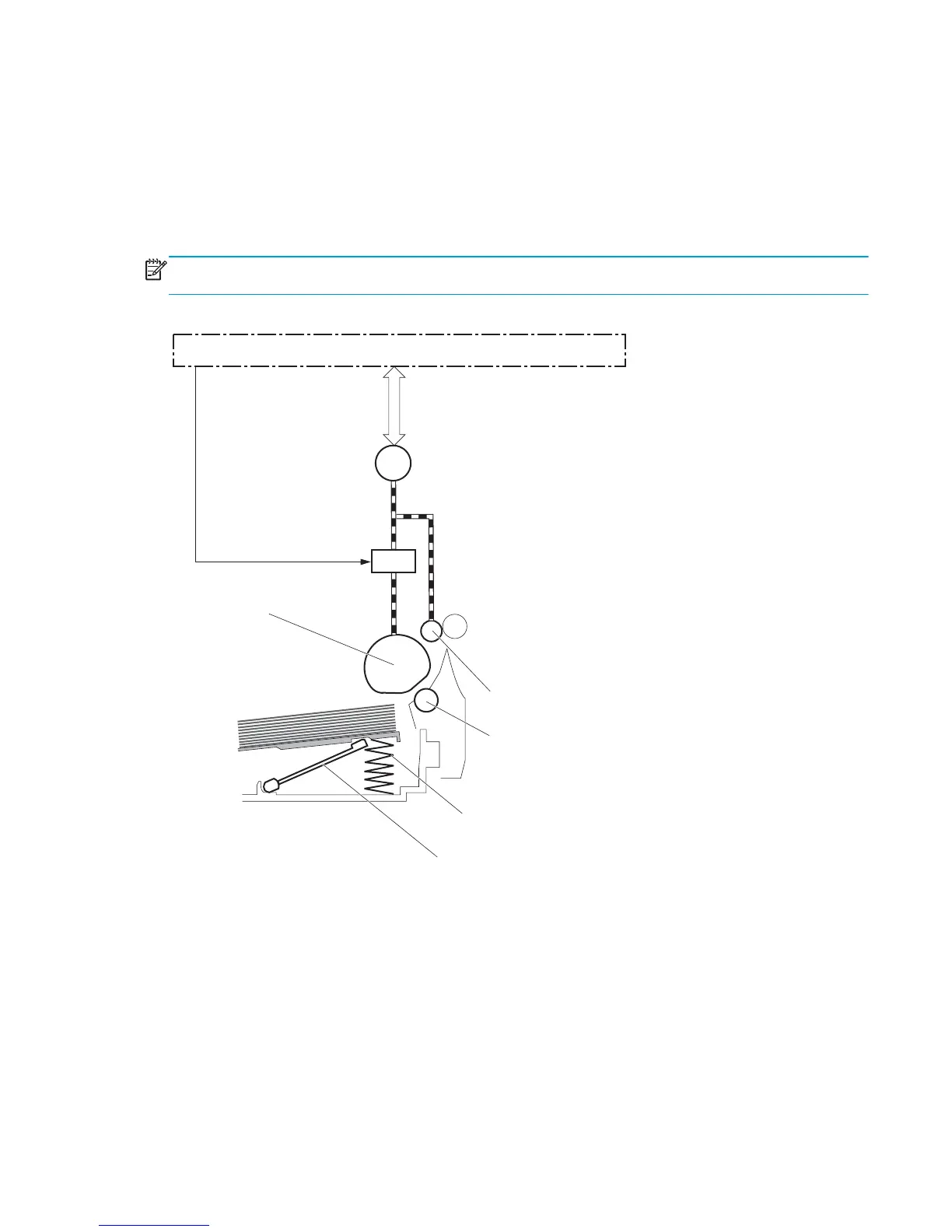

4. The Tray 2 cassette (CST) feed roller rotates.

5. The Tray 2 cassette (CST) pickup solenoid is driven at a specified timing.

6. The Tray 2 cassette (CST) pickup roller rotates and picks up the paper.

7. The Tray 2 cassette (CST) separation roller removes any multiple-fed sheets.

8. One sheet of paper is fed into the product.

NOTE: The lift-up operation pushes up the lifting plate to keep the stack surface of paper at the pickup

position.

Figure 1-34 Tray 2 cassette pickup operation

SL1

M5

DC controller

Pickup motor

CST pickup solenoid

CST pickup roller

CST feed roller

CST separation roller

Lifter

Lifting plate spring

Tray 2 cassette multiple-feed prevention

The product uses a separation roller method to prevent multiple sheets of print media from entering the

paper path. The Tray 2 cassette separation roller does not have its own driving force. Therefore the Tray 2

cassette separation roller follows the rotation of the Tray 2 cassette pickup roller.

During normal feed, when the product picks up one piece of paper, the Tray 2 cassette separation roller is

driven by the Tray 2 cassette pickup roller through one sheet of paper. Thus the separation roller rotates in

the paper feed direction.

During multiple-feed, when the product picks up more than one piece of paper, the low friction force between

the sheets weakens the driving force from the Tray 2 cassette pickup roller. In addition, some braking force is

ENWW Pickup, feed, and delivery system 47

Loading...

Loading...