OUTSIDE UK: +44 (0) 1670 700 018

11

Setting Torque

Once the system is fully connected and proper power supply available, it is time to adjust the pump

pressure to the level needed on your job.

When tightening, use the manufacturer’s specications to determine the torque value which you will

ultimately require.

Torque sequence may vary from plant to plant and even within individual plants, depending upon the

gasket material, etc. Always abide by local procedures.

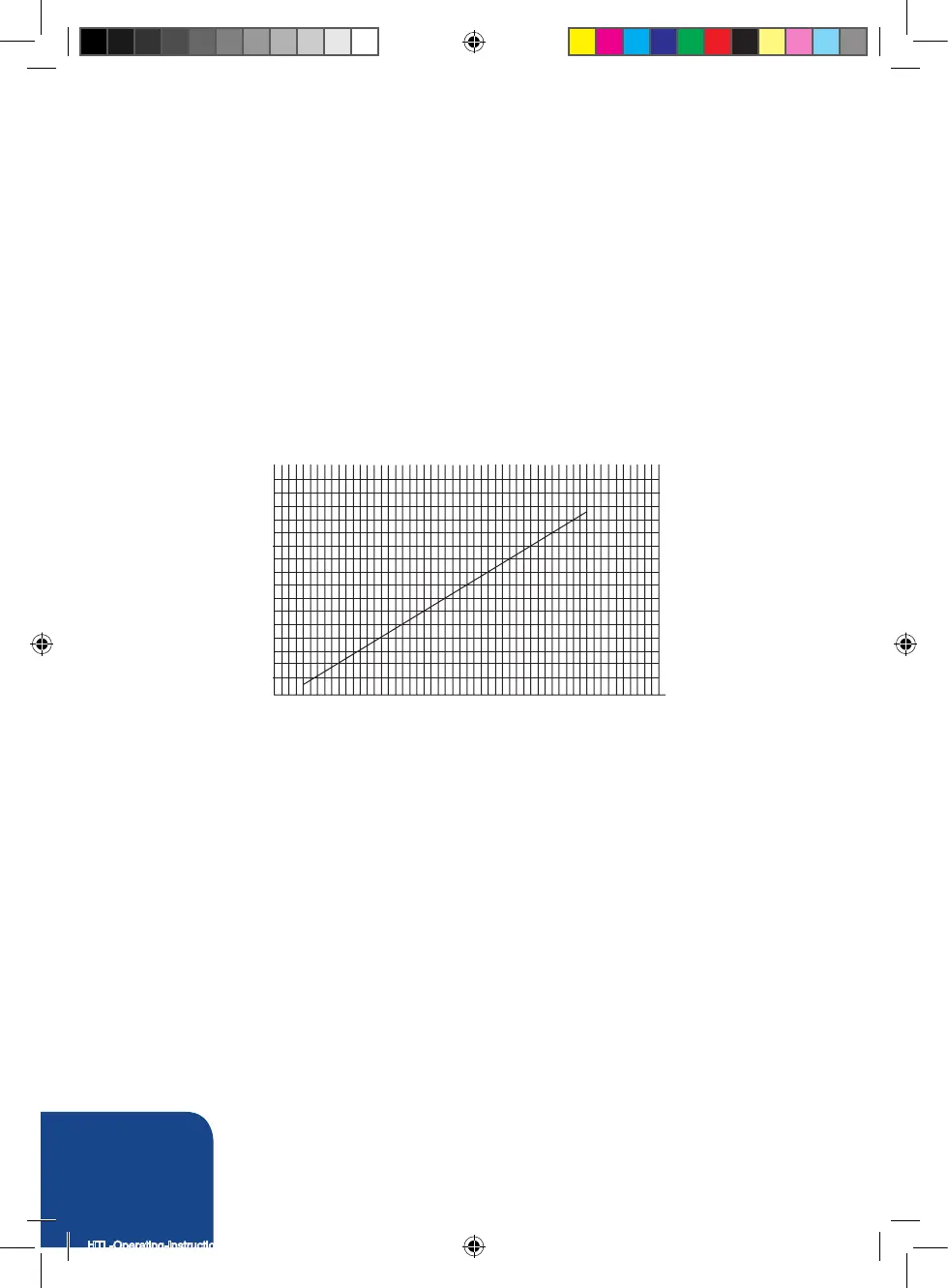

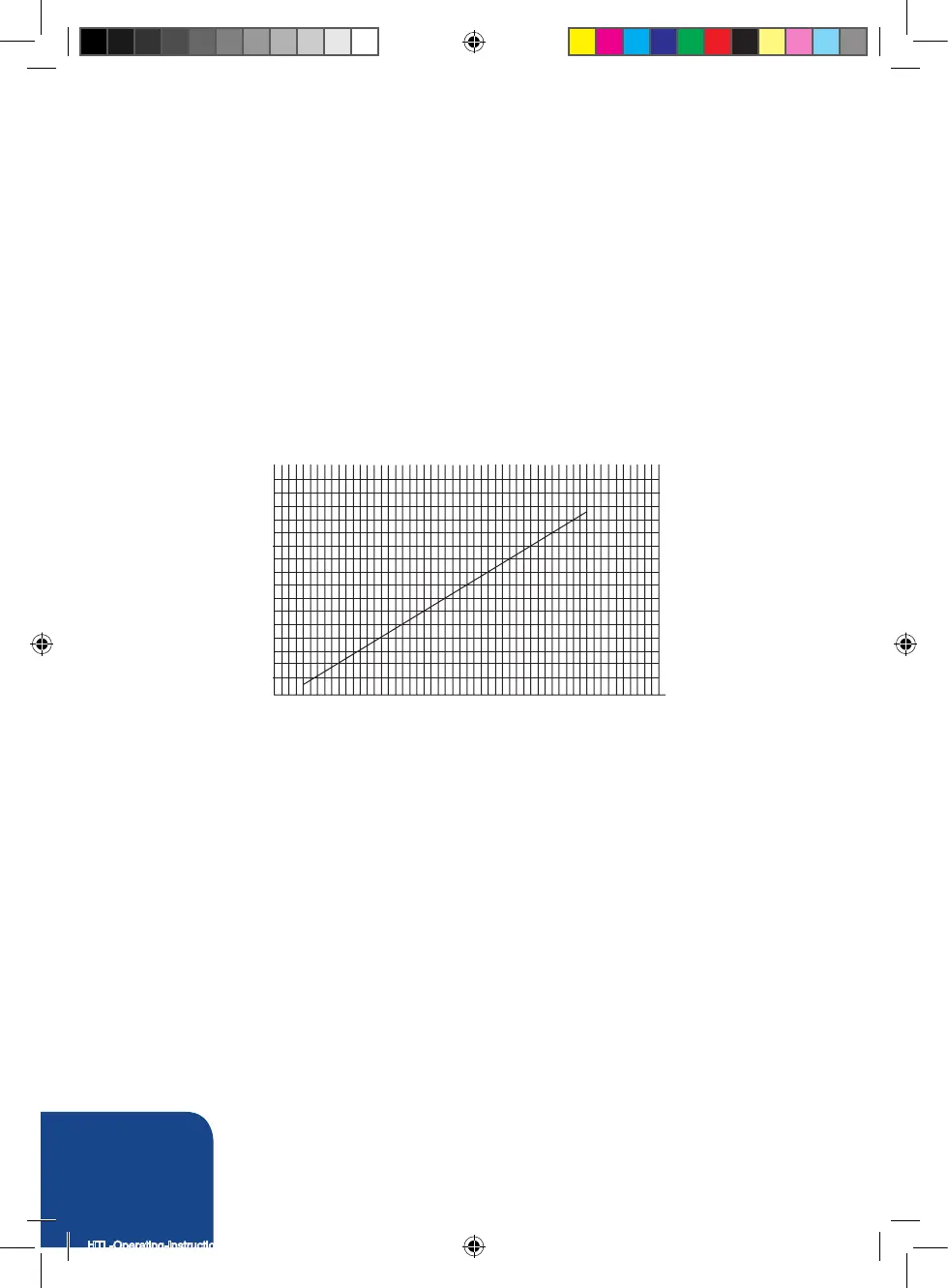

Next, use the pressure-torque conversion chart that is provided for the individual tool, similar to the one

below.

An example of nding the torque required is as follows:

Assume you are going to use a HTL-W2 tool to torque a 1 ¼ bolt to 835 ft.lbs.

1. First check the serial no. on the tool corresponds to the torque chart. On the left hand side of the

chart is the torque values. Find 835 ft.lbs on column

2. Then move across the chart until you come to a diagonal line.

3. At this point, move down to the bottom of the chart. The corresponding pressure value can be

found

4. For example the pressure is 5,300 psi on a tool to produce 835 ft.lbs.

5. Now set pressure on pump as follows in next section.

10,000 PSI = 1633 FT. LBS

1800

1700

1600

1500

1400

1300

1200

1100

1000

900

800

700

600

500

400

300

200

100

1000 PSI= 1171FT.LBS

0 1000 2000 3000 4000 5000 6000

7000 8000 9000 10000 11000

IN PUT (PSI)

Calibration Readout

Torque Values FT/Lbs

HTL-Operating-Instructions-DS.indd 12 11/04/2017 10:15

Loading...

Loading...