20

OUTSIDE UK: +44 (0) 1670 700 018

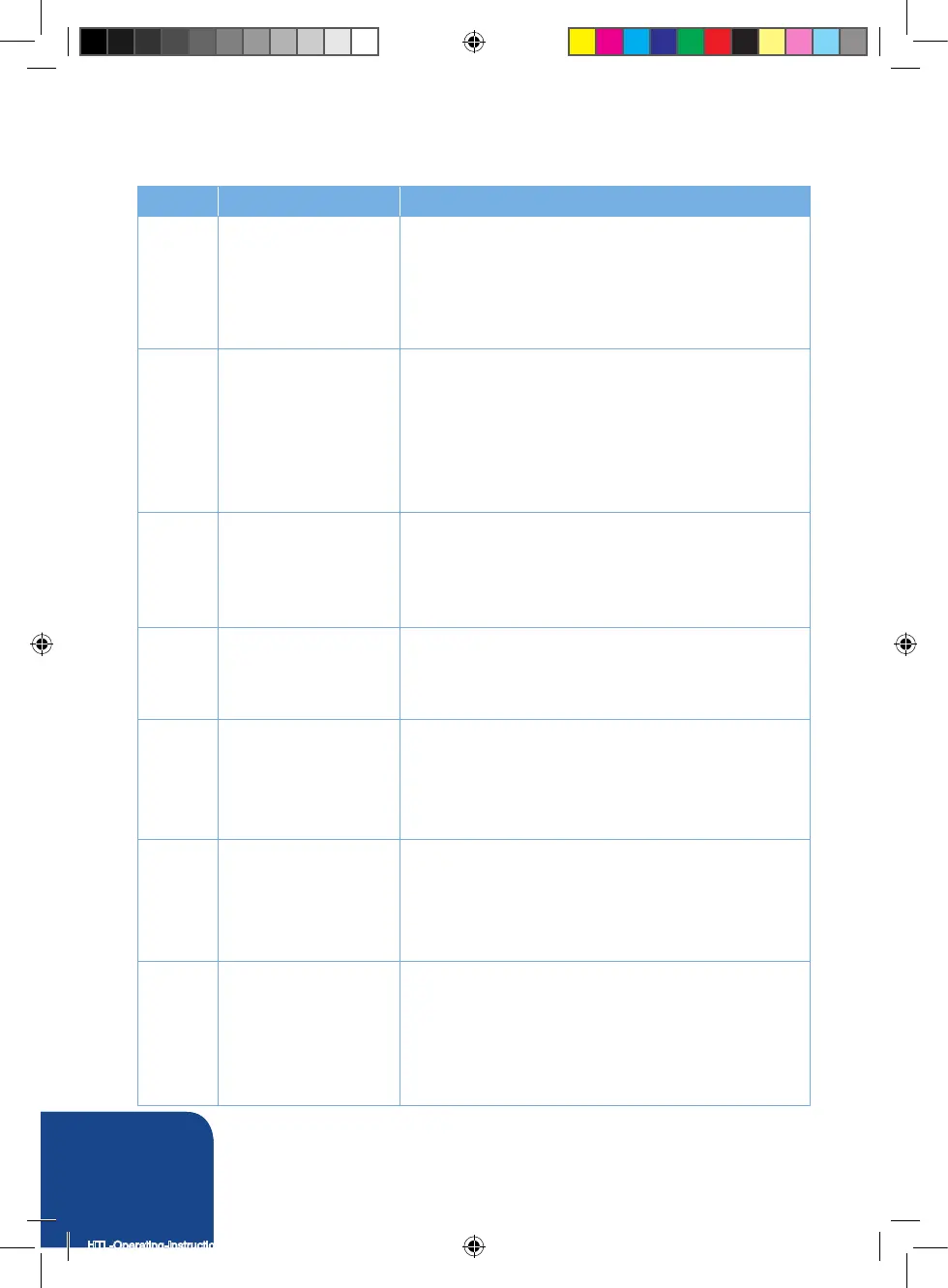

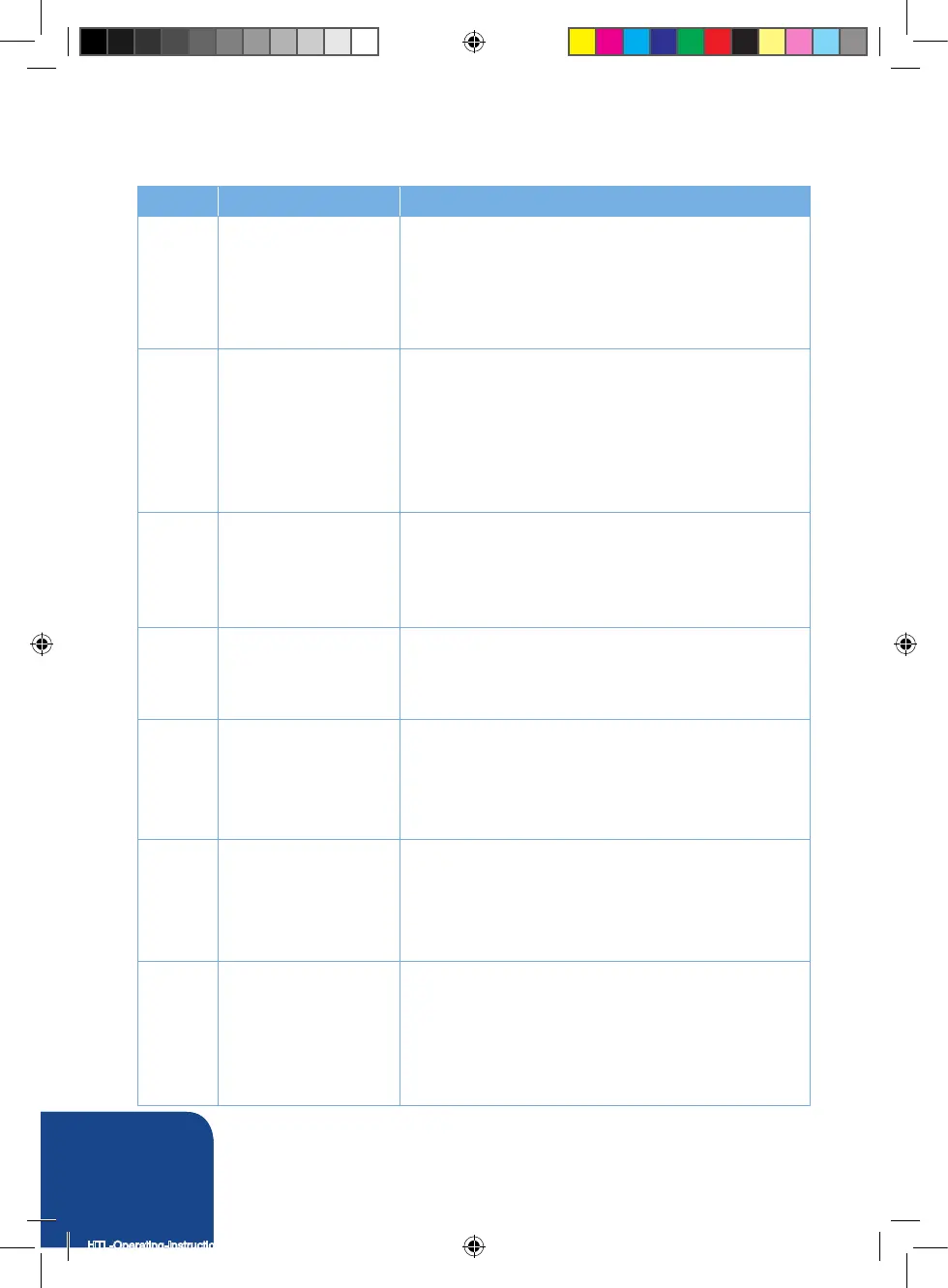

Symptom Probable Cause Action Required

Gauge

records no

pressure.

1. Gauge connection is

loose.

2. Bad gauge.

3. Pump will not build

pressure.

4. Tool seals are blown.

1. Tighten coupling.

2. Replace gauge

3. Return to HTL

4. Replace defective seals. Return to HTL.

Pump will

not build

pressure.

1. Air or electric supply

is low.

2. Defective relief or

regulator valve.

3. Low oil or clogged lter.

4. Internal leak in oil line

from external relief valve

to pump body.

5. Worn sub-plate.

1. Check air pressure or voltage.

2. Replace valve Return to HTL.

3. Fill reservoir and clean lter.

4. Open reservoir, inspect oil line while trying to build pressure if leaking

tighten ttings or replace.

5. See cylinder pressure will not build pressure above.

Motor

slow and

inecient

Sounds

laboured.

Slow

to build

pressure.

1. Air or electric supply

is low.

2. Clogged lter.

1. See #1 in preceding block

2. Clean or replace lter

Pump

heats

up.

1. Improper use.

2. Remote control is left in.

3. On position when pump

is not actively in use.

1. Have operator release advance stroke after accuracy assurance

levers spring forward.

2. Turn pump o whenever not actually being used. DO NOT leave pump

running when tool is not in use.

Hose or tool

tting is

damaged or

leaks.

1. Broken or melted plastic

outer covering.

2. Frayed Kevlar or steel

strands.

3. Oil leaks through bers.

4. Broken ttings.

1. If underlying Kevlar or steel is still intact continue operation. Inspect

frequently.

2. Cut hose in half and discard. Replace hose.

3. Remove old tting and replace with STEEL high pressure ttings only.

Electric

pump will

not run.

1. Loose electric

connections in control

box.

2. Bad brushes.

3. Motor burned up.

1. Replace motor components whichever is

necessary. Return to HTL.

2. Change defect fuse.

Tool locks

on to nut.

1. Drive segment is loaded

when the tool is maxed

out in torque.

2. Tool is operating

backwards.

3. Tool is wedged under a

xed object.

1. Press advance button on remote and build pressure - continue to

press down on remote while pulling back on one of the accuracy

assurance levers - release remote while continuing to hold back on

levers.

2. Push advance button down - tool should immediately fall free.

3. Remove shroud from around ratchet. Using any tool available, pry the

drive segment out of the ratchet and at the same time pull back on the

accuracy assurance levers. Tool should swing free or burnaway the

socket or obstruction.

19

Troubleshooting

HTL-Operating-Instructions-DS.indd 20 11/04/2017 10:15

Loading...

Loading...