5

4

Electrical Connections

Preparing Cables

4.1

Recommended Specifications

Outdoor copper cable with a cross

-sectional area of 4–6 mm

2

RS485 communications cable

-core or multi-core cable with a cross-sectional area of 0.2–

-core or multi-core cable with a cross-sectional area of 0.2–

For details about the cables and cable connection operations,

see the documents

delivered with the PT100/PT1000.

-core cable with a cross-sectional area of 0.2–1.5 mm

2

or

–16 AWG

• Connect cables in accordance with the installation laws and regulations of the country or region

where the project is located.

• Before connecting cables to ports, leave enough slack to reduce the tension on the cables and

prevent poor cable connections.

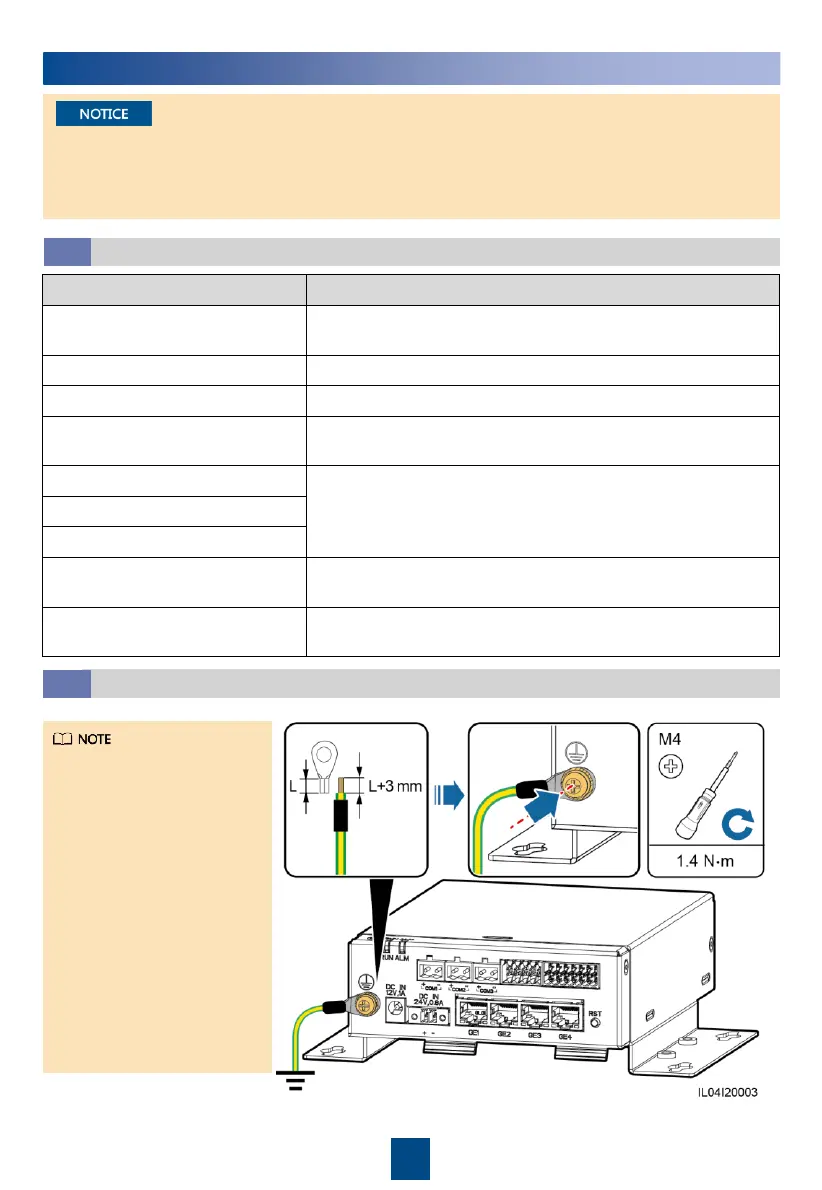

Connecting the PE Cable

4.2

• To enhance the

corrosion resistance of

the ground terminal,

you are advised to

apply silica gel or paint

on it after connecting

the ground cable.

• If the SmartLogger is

connected to the

SmartModule over a

connecting plate,

connect a PE cable to

the ground point of the

SmartLogger or

SmartModule based on

site requirements.

Loading...

Loading...