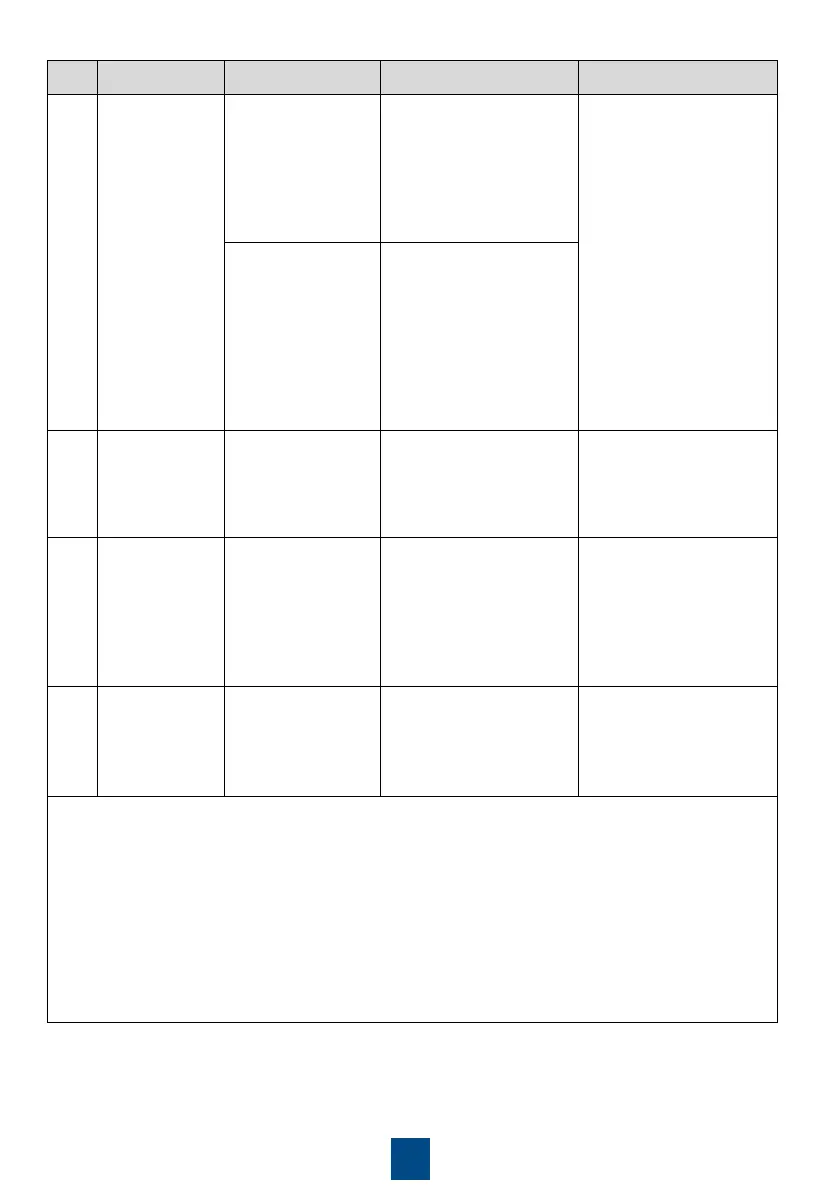

Conductor cross-

sectional area: 50–

240 mm

2

24–66 mm (multi-

core); 14–32 mm

(single-core)

If you choose the ground

point in the maintenance

compartment for

connecting a PE cable,

use a four

core cable or three

single

Conductor cross-

sectional area: 70–

240 mm

2

(multi-

core); 70–240 mm

2

(single-core)

24–66 mm (multi-

core); 14–32 mm

(single-core)

PV cable that

meets the 1500 V

standard

Conductor cross-

sectional area: 4–6

mm

2

RS485

communication

s cable

Outdoor shielded

twisted pair cable

Conductor cross-

sectional area: 0.25–

When three

communications cables

connect to the signal

cable connector, the

outer diameter of the

cables should be 4

(Optional)

Power cable of

the tracking

system

core outdoor

copper cable with

dual

Conductor cross-

sectional area: 10

mm

2

Note [1]: The value is valid only if the conductors of the PE cable and AC power cable use the

same material. If the materials are different, ensure that the conductor cross

sectional area of the

PE cable produces a conductance equivalent to that of the area S/2. The specifications of the PE

cable are subject to this table or calculated according to IEC 60364

Note [2]: You are advised to use a soft cable to prevent poor terminal contact due to the bending

stress of the cable.

Note

[3]: For some models, the outer diameter of a single-core cable ranges from 14 mm to 36

mm based on the label in the maintenance compartment.

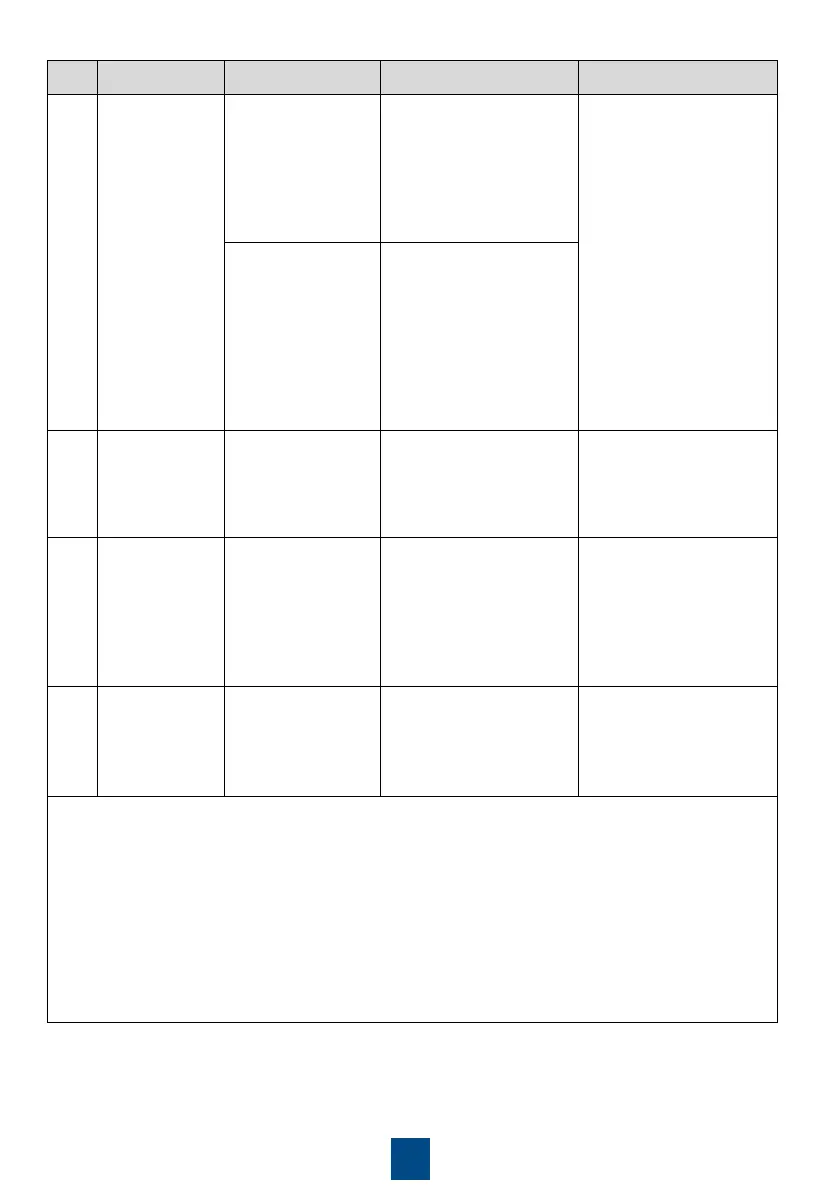

Note [4]: For some models, when the OT/DT terminal is crimped as shown in the following figure

and the rubber baffle plate of the AC wiring terminal is 112 mm, the maximum conductor cross

sectional area of the single

-core cable can be 400 mm

2

.

Loading...

Loading...