8

202 Series Tooling (HK938) Alcoa Fastening Systems

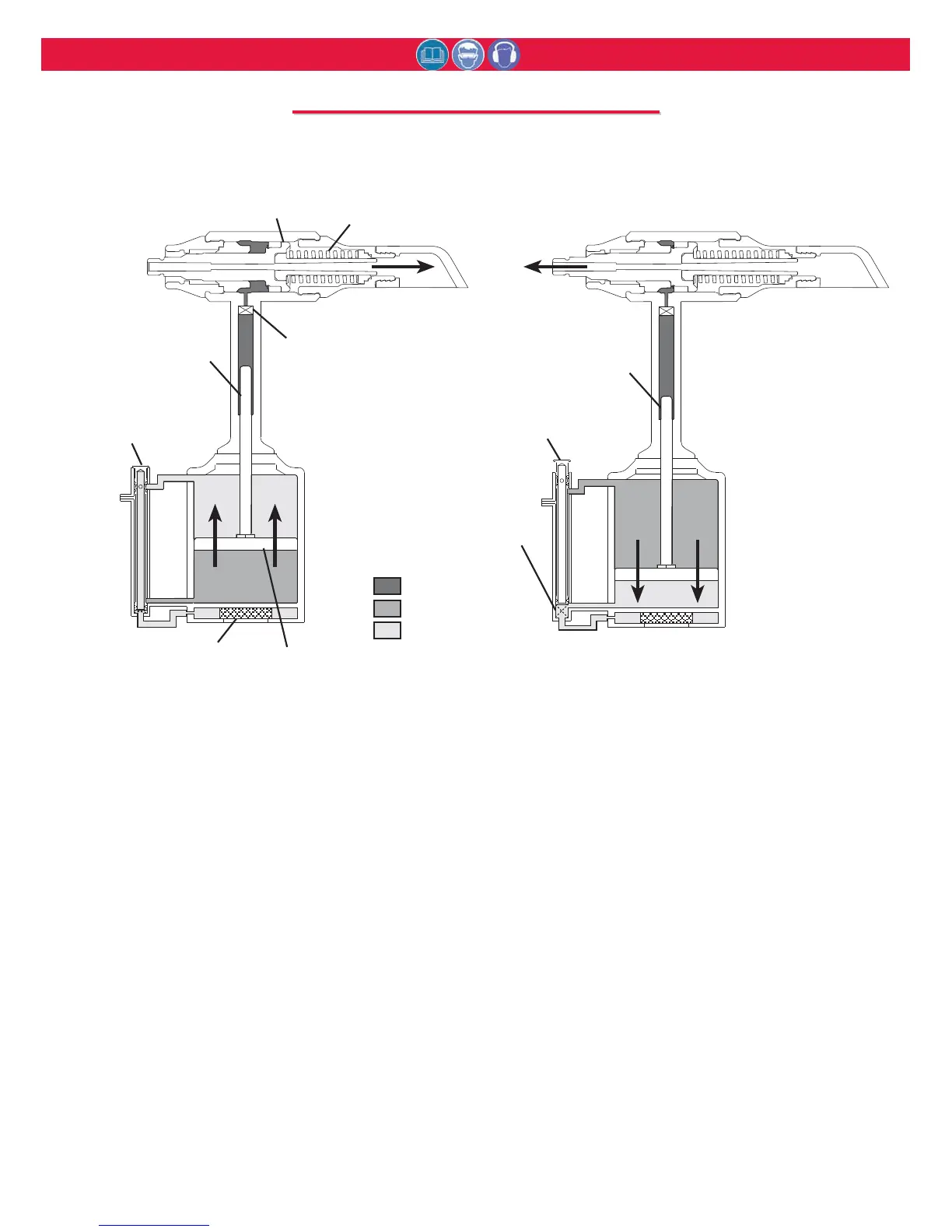

When the tool is connected to proper air supply, the air pressure holds

the Throttle Valve in the up (RETURN) position.

PULL STROKE

RETURN STROKE

P

P

RINCIPLE

RINCIPLE

OF

OF

O

O

PERATION

PERATION

When the tool is connected to the air supply, air

pressure holds the Throttle Valve in the UP

position, and air pressure is directed to the top of

the Air Piston keeping it down.

When the trigger is depressed, the Throttle

Valve moves to the DOWN position, and

pressurized air is directed to the bottom of the

Air Piston, causing it to move upward (Fig.2a).

The air above the piston is exhausted and

directed through the center of the Throttle Valve

and out the bottom of the tool through the

Muffler.

As the Hydraulic Piston Rod moves upward, a

column of fluid is forced into the tool head,

which moves the PULL Piston rearward. The

attached nose assembly moves with the PULL

Piston to start fastener installation.

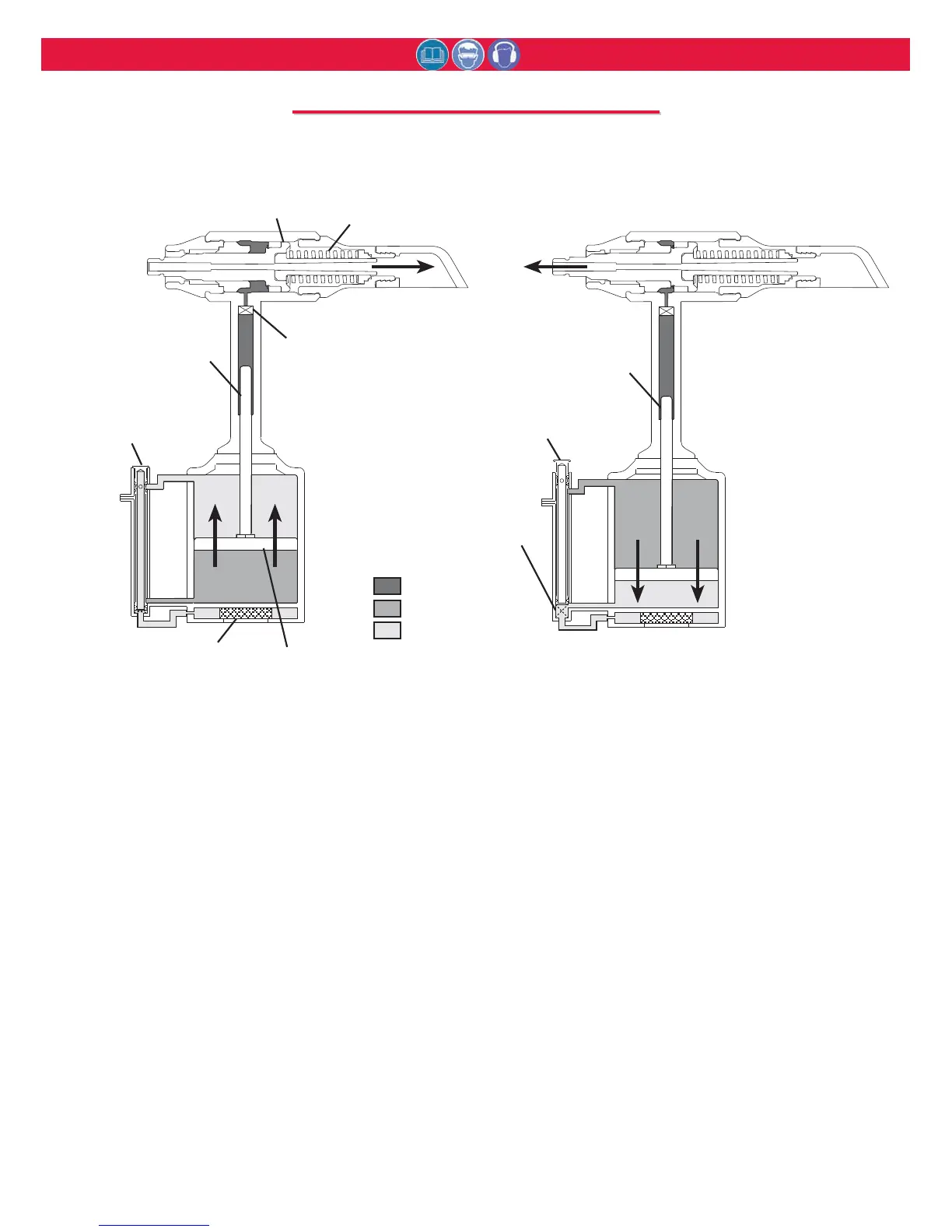

When fastener installation is completed, and

upon trigger release, air pressure with the

assistance of a Throttle Valve Spring causes the

Throttle Valve to return to its UP position.

Pressurized air is re-directed to the top of the

Air Piston (Fig.2b), causing the Air Piston and

Hydraulic Piston Rod to move downward. The

air from below the piston is exhausted through

the Muffler at the bottom of the tool.

As the Hydraulic Piston Rod moves downward

and hydraulic pressure is released from the

PULL Piston, a Spring behind the PULL

Piston returns it to its forward position.

The Damper Valve impedes oil flow at pinbreak

helping prevent “Tool Kick”.

Fig. 2a

Fig. 2b

Loading...

Loading...