11

202 Series Tooling (HK938) Alcoa Fastening Systems

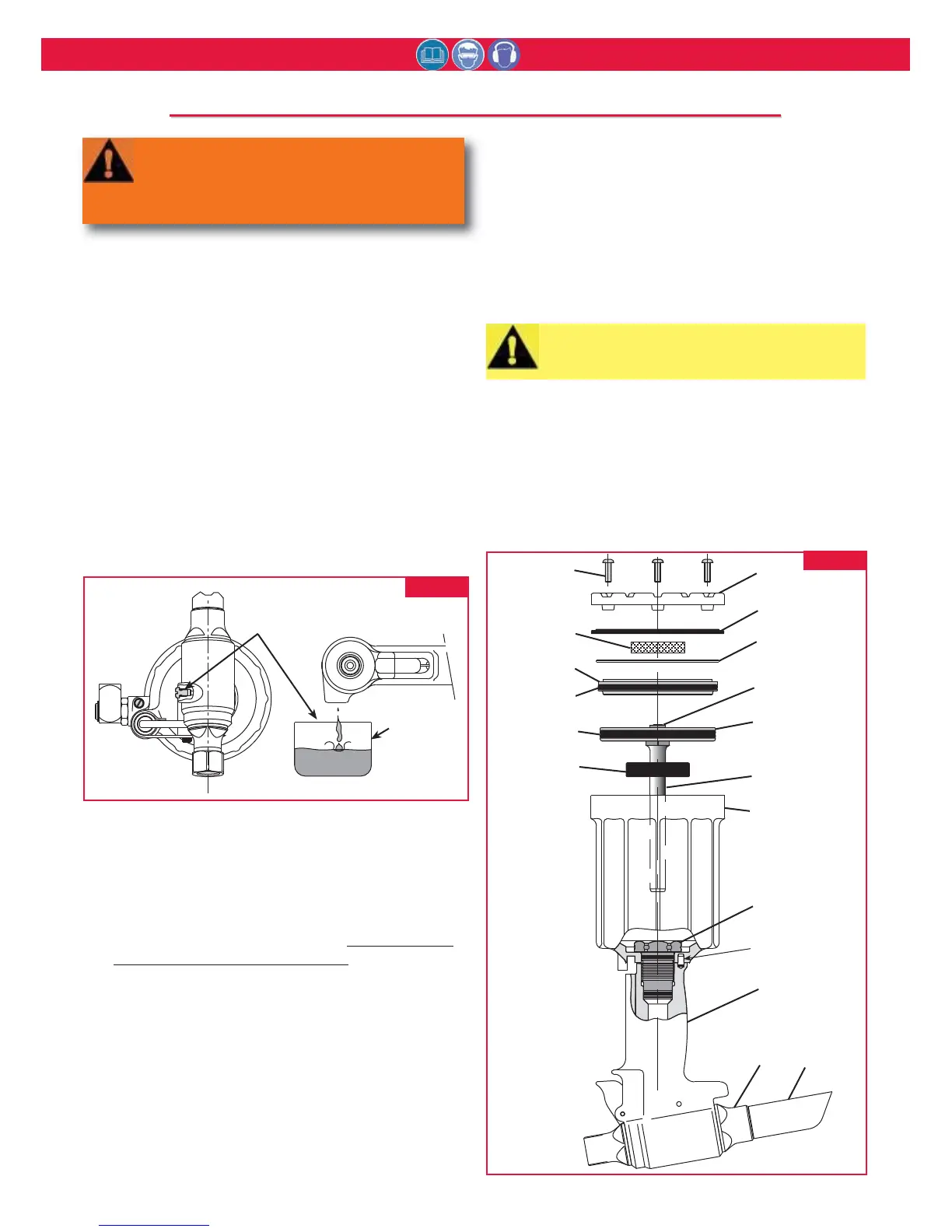

For component identification, refer to Figures 14 & 15

and Parts Lists on pages 20 & 21.

NOTE: The following procedure is for complete

disassembly of tool. Disassemble only

components necessary to replace damaged O-

rings, Quad rings, Back-up rings, and worn or

damaged components. Always use soft jaw vice to

avoid damage to tool.

1. Disconnect tool from air source.

2. Unscrew Retaining Nut (7) and remove nose

assembly.

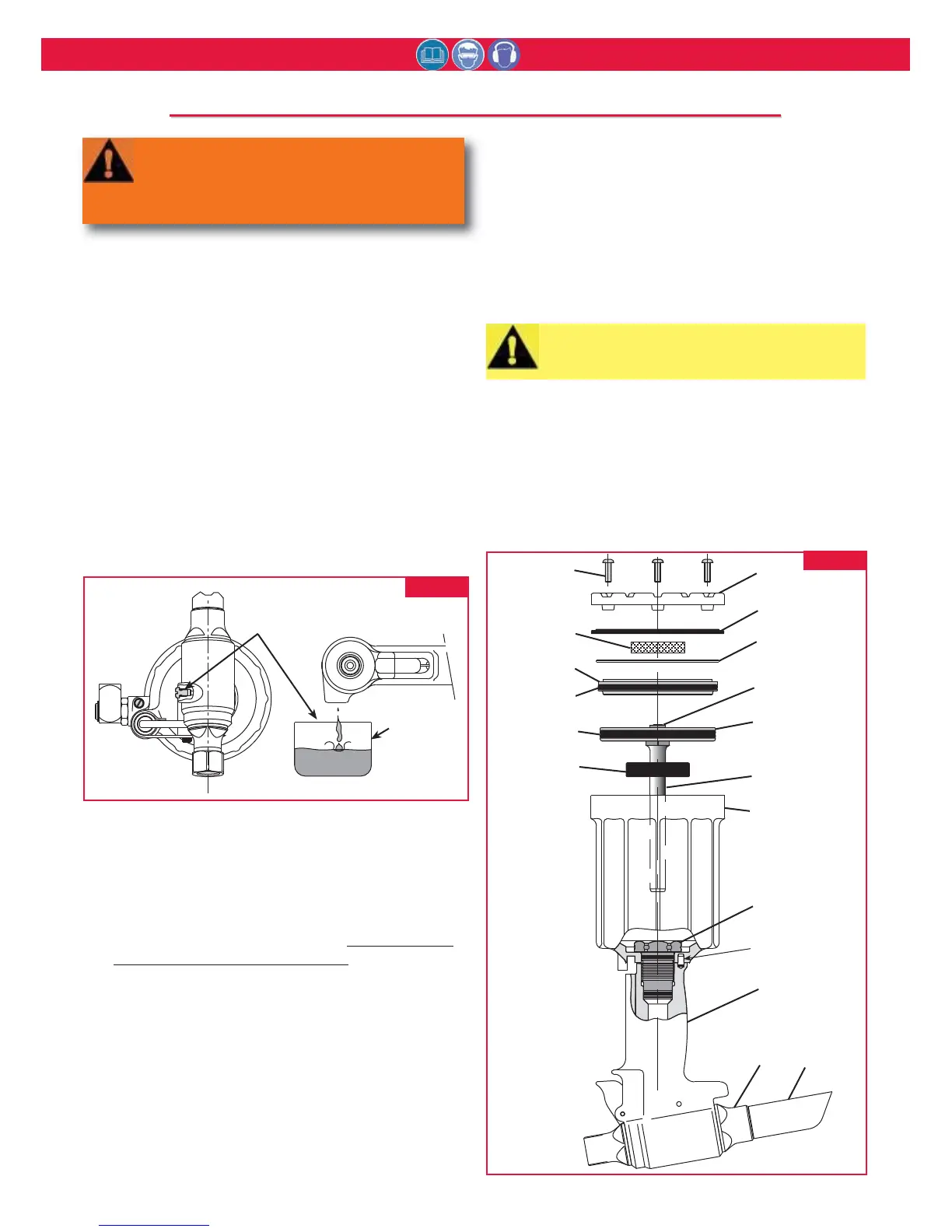

3. Unscrew Bleed Plug (55), from top of

Handle/head. Turn tool over and allow fluid to

drain into container (Fig. 1). Discard fluid.

4. 202 & 202L: Pull Pintail Deflector (24) off of End

Cap (21). (Figure 2)

202B: By reaching through the window of Pintail

Bottle (24) remove Retaining Ring (62) and

Washer (63), then remove Pintail Bottle (24) and

Adapter (64). (Figure 5).

202V & 202LV: Please reference Disassembly of

Pintail Bottle and Vacuum System Procedure.

5. Remove Throttle Arm Pivot Screw (48) and Lever

Guard (73), and lift out Throttle Arm (53).

Disconnect ball end of Cable Assembly (2) from

Throttle Arm.

6. Hold tool in vise with bottom up. (Fig. 2) Remove

Button Head Screws (40) with 1/8 hex key.

Remove End Cap (41) and Gasket (39). Remove

Muffler (42) from end cap. Remove Spring (49)

from Throttle Valve (Fig.14).

7. Tap Cylinder Head (45) down with soft mallet (to

take pressure off ring), and remove Retaining Ring

(38) (Fig.2).

8. Screw Button Head Screws (40) back into

Cylinder Head. Carefully pry on screws to remove

head. Remove O-ring (46).

9. To remove air piston from cylinder, pull on Lock

Nut (43) with vise grips. Remove Quad Ring (47).

10. Remove Bumper (34) from Gland Assembly.

Unscrew Gland Assembly (25) with 1 3/8 socket

wrench and extension bar.

11. First remove Retaining Ring (30) from Gland (26).

Pull out Spacer (29) and Polyseal (28). Then

remove O-rings (31 & 27), Quad Ring (33), &

Back-up Ring (32) (Fig. 14).

drain hydraulic fluid.

Loading...

Loading...