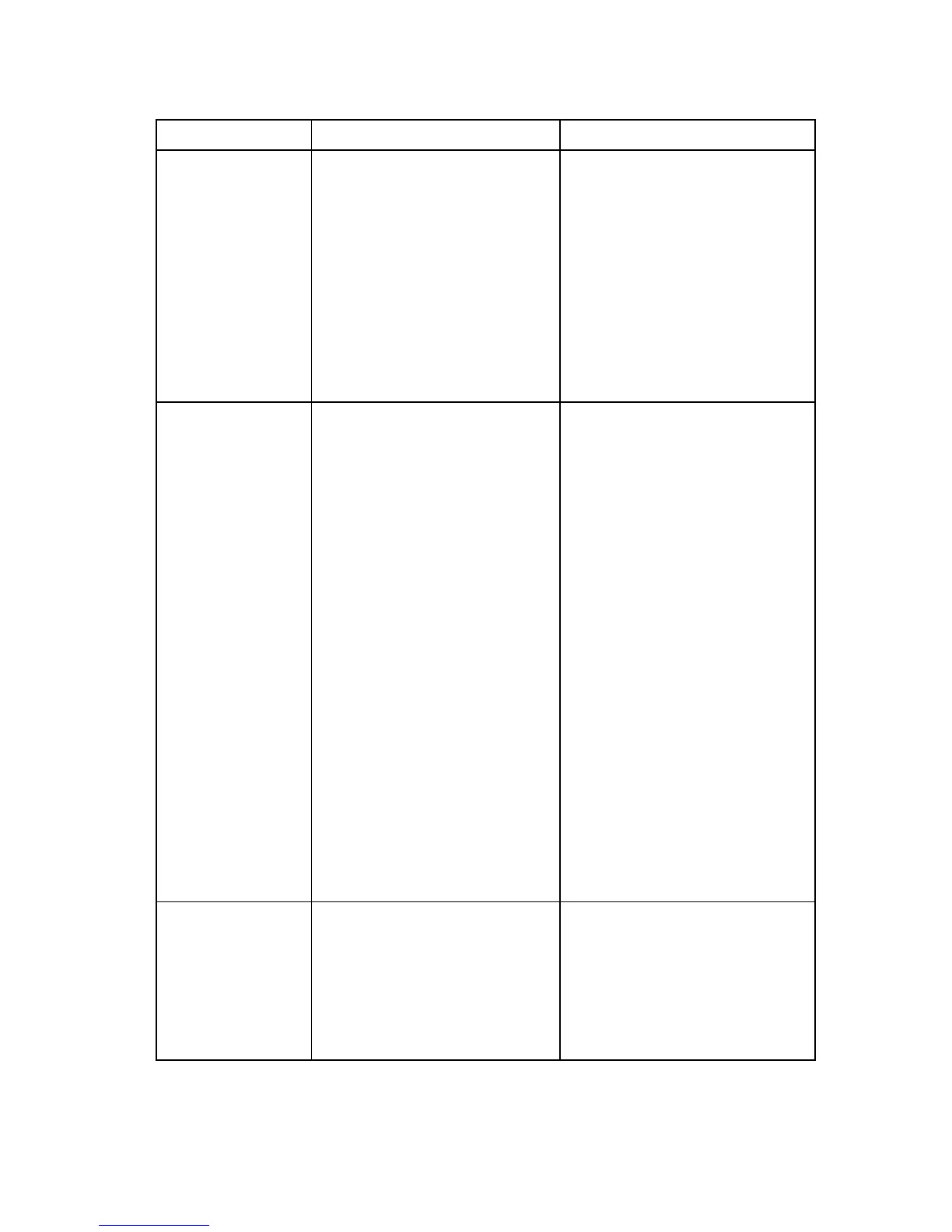

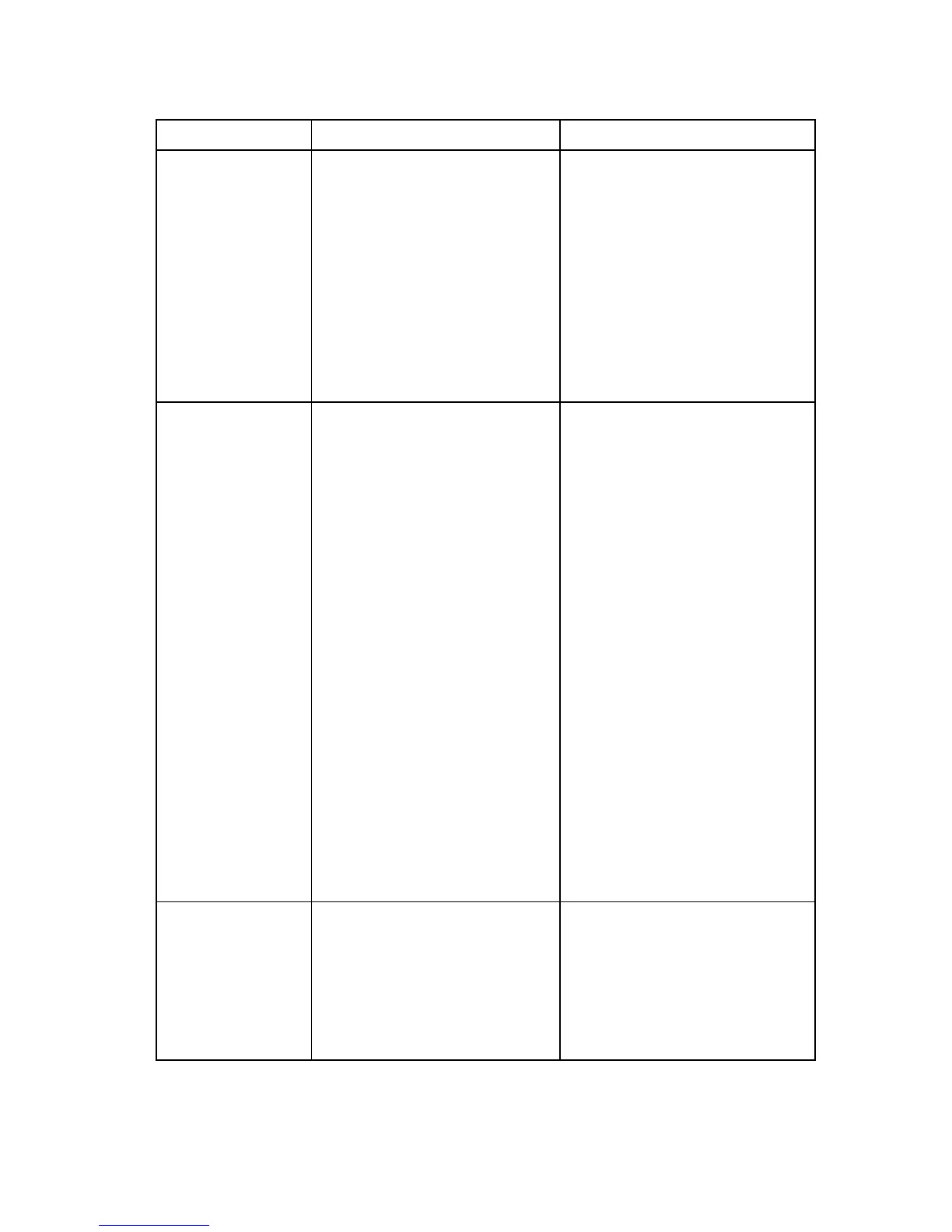

PROBLEM CAUSE CORRECTION

Compressor is

not supplying

enough air to

operate

accessories.

Prolonged excessive use of

air.

Compressor is not large

enough for air requirement.

Hole in hose. Air leaks.

Decrease amount of air usage.

Check the accessory air

requirement. If it is higher

than the SCFM or pressure

supplied by your air

compressor, you need a larger

compressor.

Check and replace if required.

Tighten any exposed fittings.

Motor will not

run.

1. Fuse blown, circuit

breaker tripped.

2. Extension cord is

wrong length or gauge.

3. Loose electrical

connections.

4. Faulty motor.

5. Overload protection

device is Open.

1. Check fuse box for

blown fuse and replace as

necessary. Reset circuit

breaker. Do not use a fuse or

circuit breaker with higher

rating than that specified for

your particular branch circuit.

Check for proper fuse. You

should use a time delay fuse.

Check for low voltage problem.

Check the extension cord.

Disconnect the other electrical

appliances from circuit or

operate the compressor on its

own branch circuit.

2. Check the extension

cord.

3. Check wiring

connection inside terminal box.

4. Have checked by a

Trained Service Technician.

5. Disconnect the power

supply, the compressor will

restart automatically when the

motor is Cool.

Pressure

gauge does

not indicate

air pressure

- Regulator valve is not

open to allow air flow

through to tool and gauge.

- Drain valve is open not

allowing tank to build up

pressure.

- Turn regulator clockwise to

open and allow air through

to tool and gauge.

- Close drain valve and turn

compressor on to fill up tank

with air.

Loading...

Loading...