voltage. If the battery voltage is satisfactory, check the

cleanliness and tightness of the terminals and ground

connections. A general understanding of electrical servicing

and use of basic test equipment is necessary for

troubleshooting and repair.

Major overhaul or repair of the starting motor or

alternator should be performed by trained technicians only.

WARNING: Always wear adequate eye

protection when servicing the hydraulic system.

Hydraulic system

IMPORTANT: Never use hydraulic or automatic

transmission fluid in this system; use only motor oil as

specified. Remember, dirt is the primary enemy of any

hydraulic system.

WARNING: Hydraulic oil escaping under

pressure can penetrate skin. Hydraulic oil may

cause infection in a minor cut or opening in the

skin. If exposed to hydraulic fluid, see a doctor

at once.

Before applying pressure to hydraulic system,

make sure all connections are tight and all hoses

and lines are in good condition. To find a leak

under pressure, use a piece of cardboard or wood

— never use your hands. Relieve all pressure in

the system before disconnecting or working on

hydraulic lines. To relieve pressure, park unit on

a flat surface and shut engine off. Stroke H-bar

lever from full forward to full reverse several

times.

The 3.9 U.S. quarts (3.69 liter) hydraulic reservoir is

located behind the fuel tank. Fig. 4-4

Check oil level in hydraulic system after every 100 hours

of operation or monthly, whichever occurs first. Check

more often if system appears to be leaking or otherwise

malfunctioning.

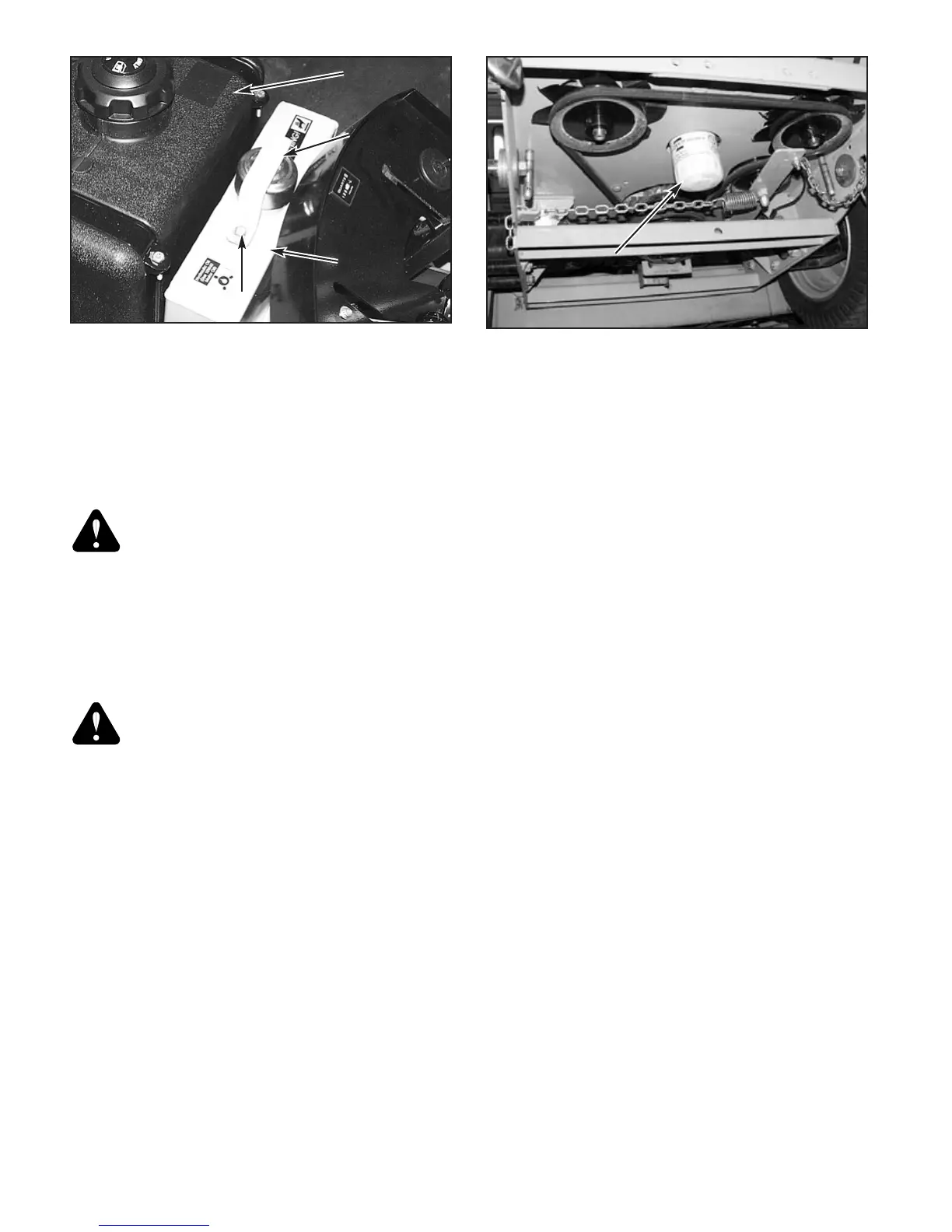

To check the oil level, loosen the cap screw that holds the

cap lock in place and pivot the lock away from the filler cap

(Fig. 4-3). Turn and pull up on the filler cap. Fluid level

should touch the bottom of screen under filler cap. Use only

SAE 10W40 SG, SF/CC, CD service motor oil.

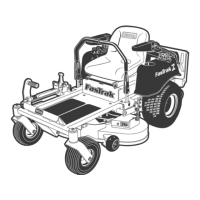

Change hydraulic system filter element (Fig. 4-4) after

first 50 hours of tractor operation, then replace filter and oil

in reservoir every 500 hours thereafter. When changing

hydraulic oil use approximately 1/2 of a 7 oz. bottle of

Lubrizol additive (Hustler P/N 027912). This additive,

available from your Hustler dealer, will increase the

performance life of the hydraulic system components.

The system filter is located under the frame platform

between the two hydraulic pumps (Fig. 4-5). A standard oil

filter wrench is used to change filter, threads are right

handed. Use the Hustler approved element only.

NOTE: The hydraulic system oil is drained by removing

the oil filter. The reservoir does not have a seperate drain

plug.

IMPORTANT: Prefill the filter element with clean oil,

before installing, to prevent drawing air into the system

pump.

1. Fill the filter element with clean system oil. Smear a

light coating of oil on upper surface of rubber seal.

2. Install the filter element on base. Tighten the oil filter

by hand until the filter seal makes contact with the

filter head, then tighten an additional 3/4 turn with a an

oil filter wrench. — DO NOT OVERTIGHTEN.

3. Start tractor engine and let run at approximately 2/3

throttle for a few minutes to work any trapped air out

of the system before engaging the steering control

lever.

4. Stop the engine and check the filter and connections

for leaks.

5. Check the hydraulic reservoir for specified oil level.

Add clean oil as necessary.

Clean or replace hydraulic reservoir cap annually. Cap

may be cleaned by dipping in or flushing with cleaning

solvent. Follow manufacturer’s instructions and warnings

for application of solvent type selected.

NOTE: The hydraulic pumps are equipped with bypass

valves. For more information refer to Operation section,

Moving tractor with stalled engine.

778845 Rev. 7/04

4-4

Figure 4-5

HHyyddrraauulliicc

ooiill ffiilltteerr

Figure 4-4

CCaapp ssccrreeww

CCaapp lloocckk

FFuueell ttaannkk

HHyyddrraauulliicc

rreesseerrvvooiirr

Loading...

Loading...