DD.026 ENG R(1)

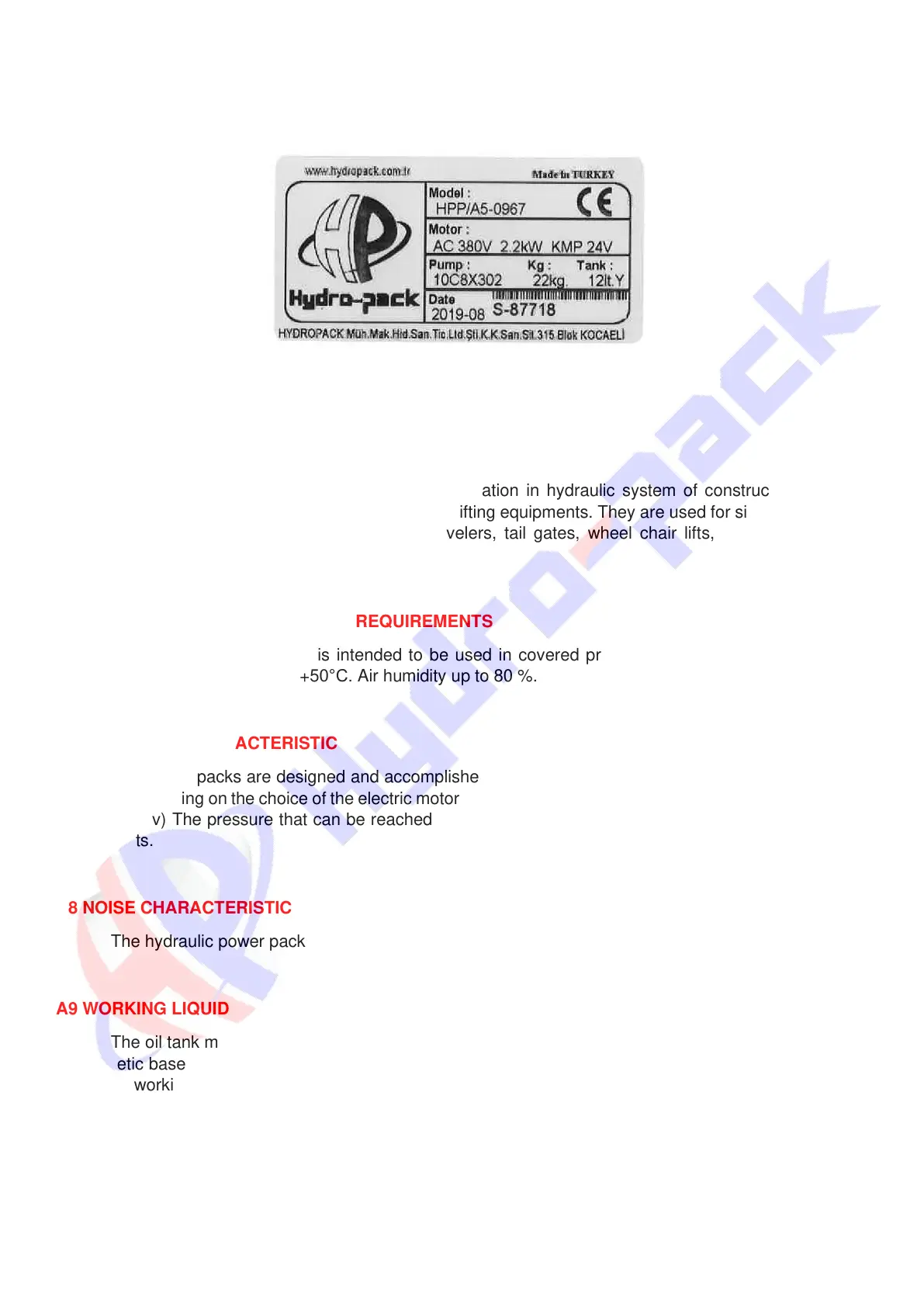

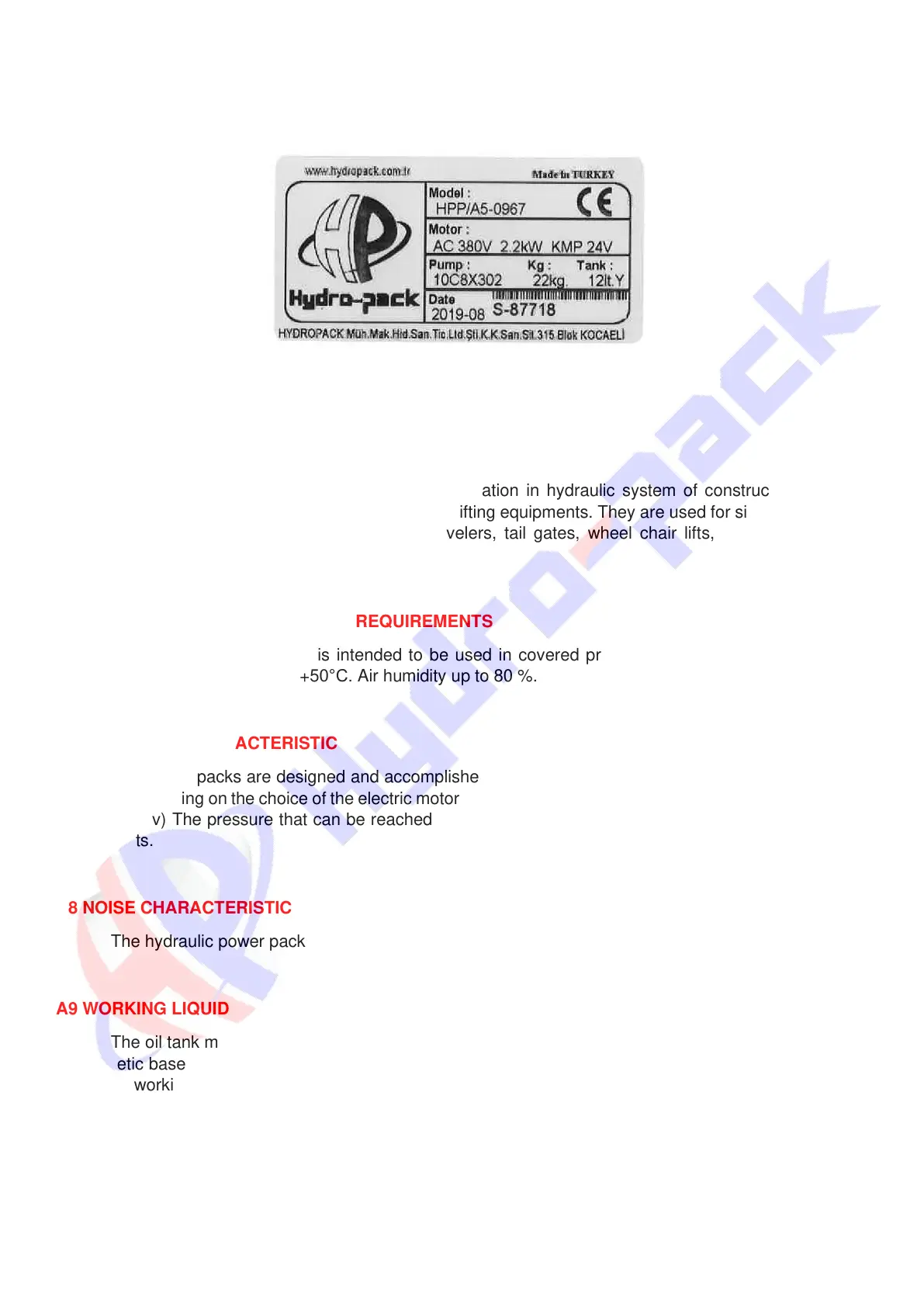

A4 LABEL

Technical information of power pack (Such as motor power, pump displacement, oil tank size, etc.)

can be seen on label. Label is located on oil tank.

Photo 1. Label of power unit

A5 APPLICATIONS

The hydraulic power pack is intended for integration in hydraulic system of construction building,

transport machines, automobiles, manually operated lifting equipments. They are used for single and double

acting systems as well. (Tippers, car lifts, dock levelers, tail gates, wheel chair lifts, snowplow, forklifts,

industrial automation, etc.

A6 PRODUCTION CONDITIONS AND REQUIREMENTS

The hydraulic power pack is intended to be used in covered premises as well as at open area at

ambient temperature of - 25 to +50°C. Air humidity up to 80 %.

A7 TECHNICAL CHARACTERISTIC

The power packs are designed and accomplished so that they produce a flow rate from 0,4 L/min to

22 L/min depending on the choice of the electric motor (0.5 kW up to 5.5 kW) and hydraulic pump (0,25 cc/rev

up to 9 cc/rev) The pressure that can be reached is from 0 to 220 bar depends on the size of the selected

components.

A8 NOISE CHARACTERISTIC

The hydraulic power pack does not emit noise higher than 85 dB in accordance to EN 60034–9.

A9 WORKING LIQUID

The oil tank must be filled with new, filtered mineral based ISO 6743/4 fluid. Hydraulic oils at mineral

or synthetic base with viscosity rate from 15 to 68 cST at temperature of 40

o

C. Hydraulic fluid may change

regarding working climate. Please do not use motor oil, diesel oil or water as fluid in the system. Class of

filtration -9 NAS 1638.

Hydraulic fluid should be changed after 6 months or 1 year depends on usage in application. Suction

filter needs to be cleaned as well.

If there is decrease on fluid level, additional oil should be put in.

Loading...

Loading...