DD.026 ENG R(1)

E5 CONNECTION TO HYDRAULIC SYSTEM

The pipelines from the power pack are connected to the implementing components of the machine.

Hydraulic circuit and technical information ca be found on technical drawing. After the final installation of the

power pack, the clean working liquid is poured into the tank to the indicated level.

E6 CONNECTION TO ELECTRICAL SYSTEM

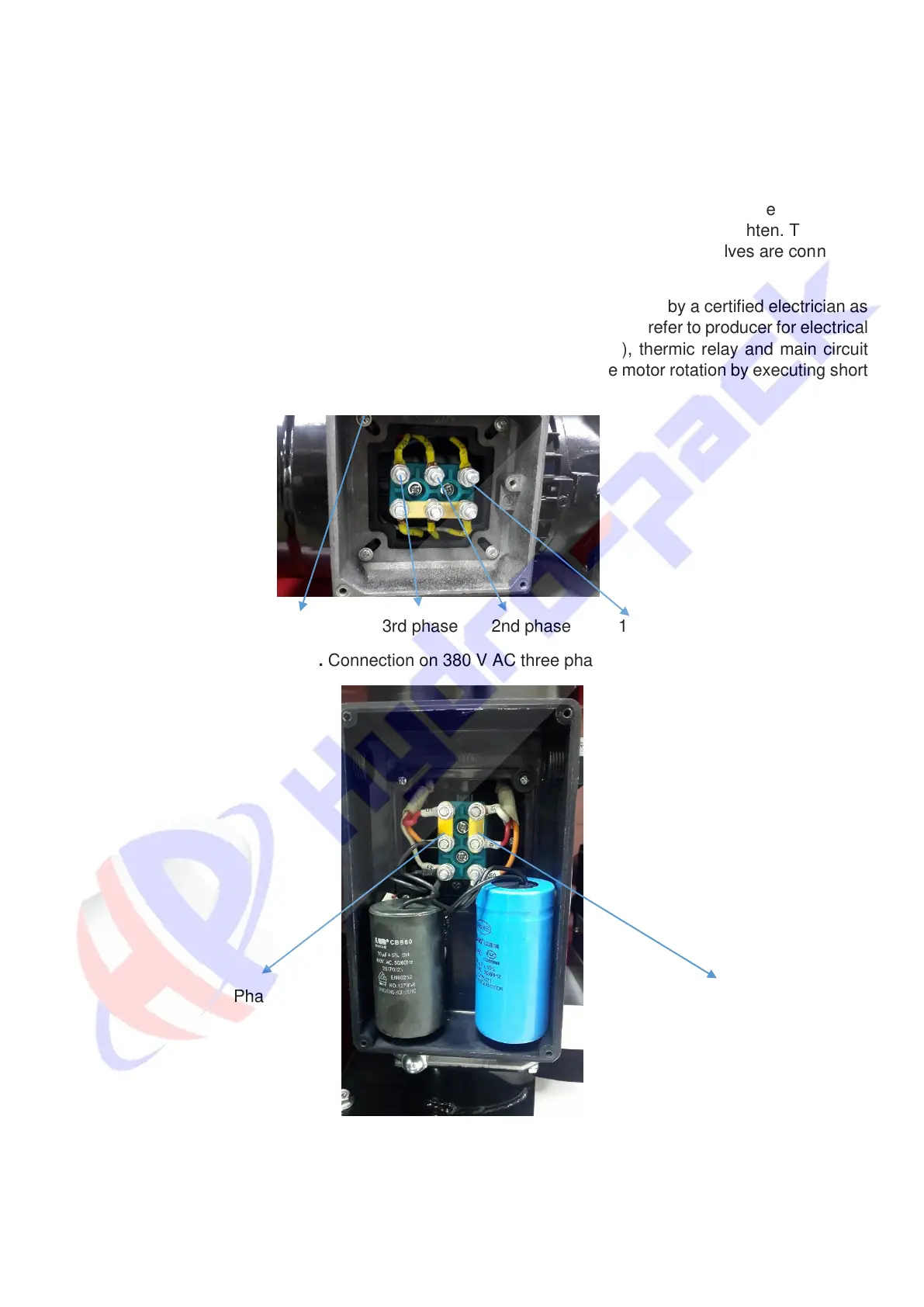

The cap of the motor terminal connecting box is removed. The nuts of the terminals are unscrewed.

The cable shoes are connected to the terminals. Then the nuts are screwed and reliably tighten. The motor

is nullified. The cap is placed at the terminal connecting box. The coils of the solenoid valves are connected

in the analogical manner. Motor rotation must be checked carefully.

The connecting of the power pack to the electrical system should be done by a certified electrician as

the rules for safety work with electrical equipments should be observed. Please refer to producer for electrical

schema. For keeping electric motor, you must use current relay (100 mA), thermic relay and main circuit

cutoff switch. After electrical connection have been made, please check the motor rotation by executing short

pulses of right rotation (from fan side) 1 second each (max.).

Grounding 3rd phase 2nd phase 1st phase

Photo 4. Connection on 380 V AC three phase motors

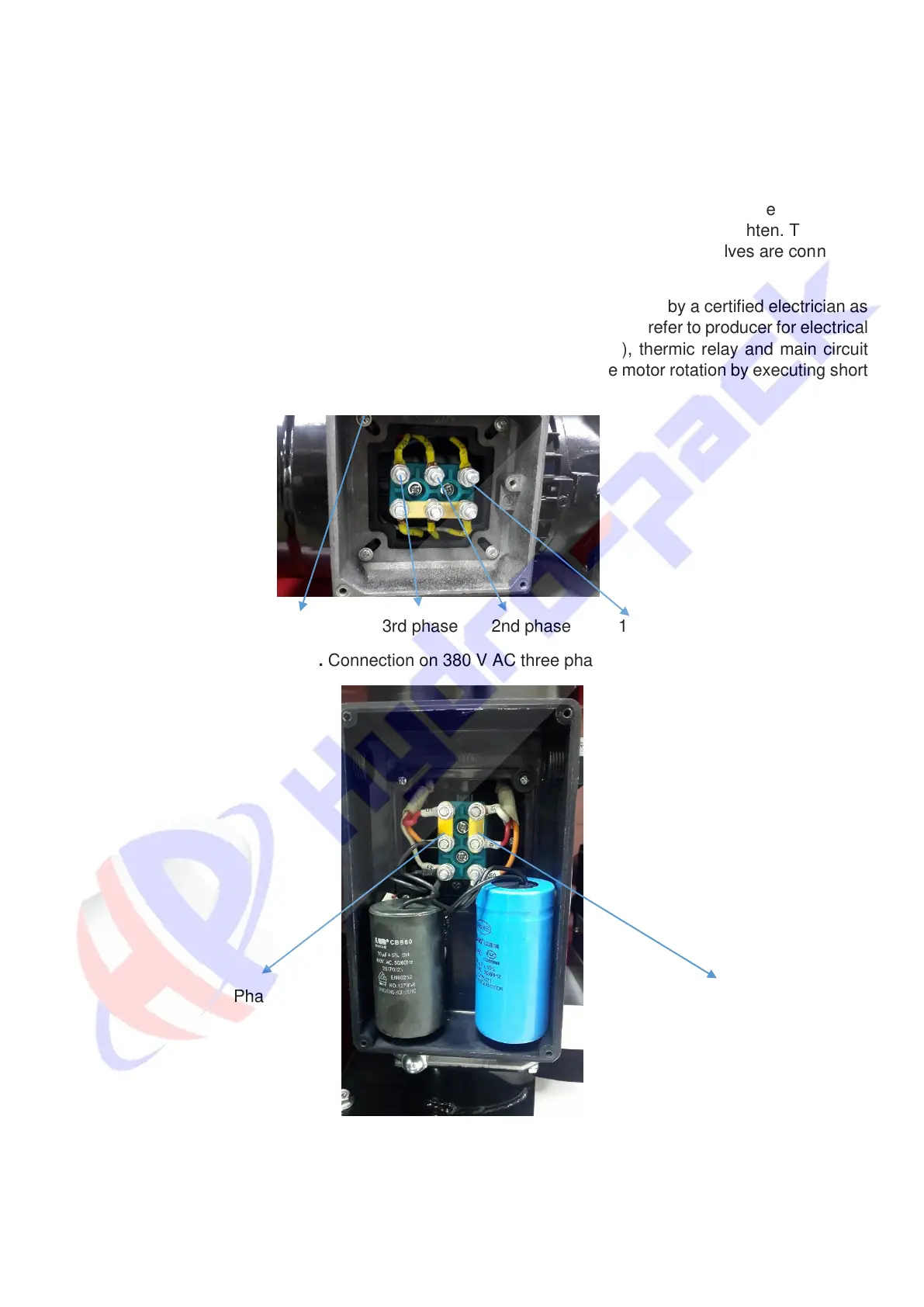

Phase

Neutral

Photo 5. Connection on 220 V AC mono phase motors*

* If mono phase motor operates in anti-clockwise rotation, please kindly check instructions located on terminal

box cover to make it right rotation.

Loading...

Loading...