16 Field Service Bulletin

HyPro2000 — HT2000 TORCH UPGRADE

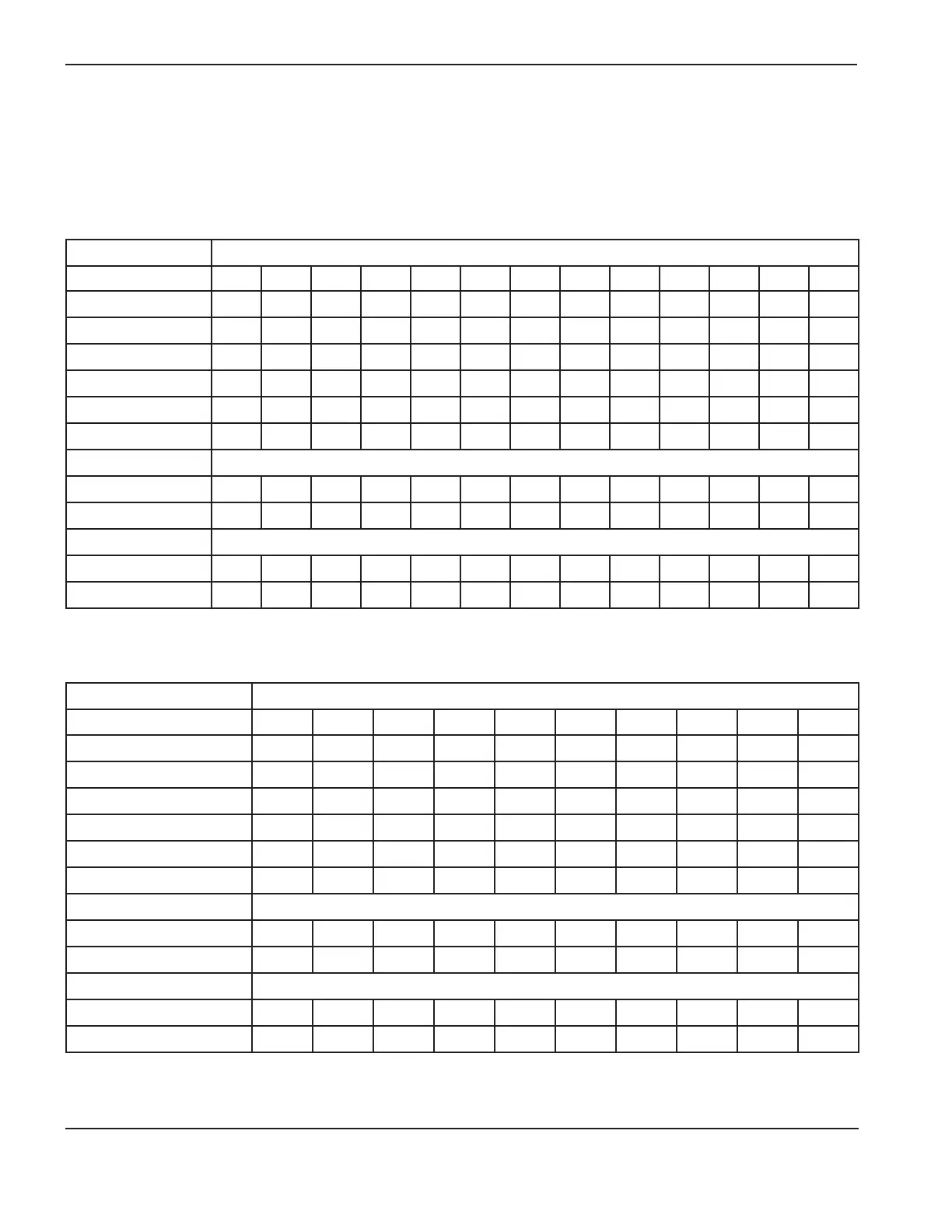

Estimated kerf width compensation

The widths in the chart below are for reference. Differences between installations and material composition may cause

actual results to vary from those shown in the tables.

Metric

Process Thickness (mm)

Mild steel 3468101215202532384450

50A O

2

/Air 1.5 1.6 –––––––––––

50A Air/Air 1.3 1.3 –––––––––––

130A O

2

/Air 2.4 2.5 2.7 2.8 2.9 3.1 3.3 3.6 4.0 – – – –

130A Air/Air 2.2 – 2.4 – 2.6 2.8 2.9 3.2 3.5 – – – –

200A O

2

/Air – – 2.8 2.9 3.0 3.3 3.4 3.7 4.1 4.6 5.0 5.4 5.9

200A Air/Air – – 2.7 – 2.9 3.1 3.4 3.6 4.0 4.5 5.0 – 5.9

Stainless steel

50A Air/Air 1.5 1.5 –––––––––––

200A N

2

/Air – – 2.5 2.6 2.7 2.9 3.1 3.3 3.7 4.1 4.5 – –

Aluminum

50A Air/Air 1.5 1.6 –––––––––––

200A N

2

/Air – – 3.2 3.3 3.4 3.6 3.8 4.1 4.6 5.1 5.6 – –

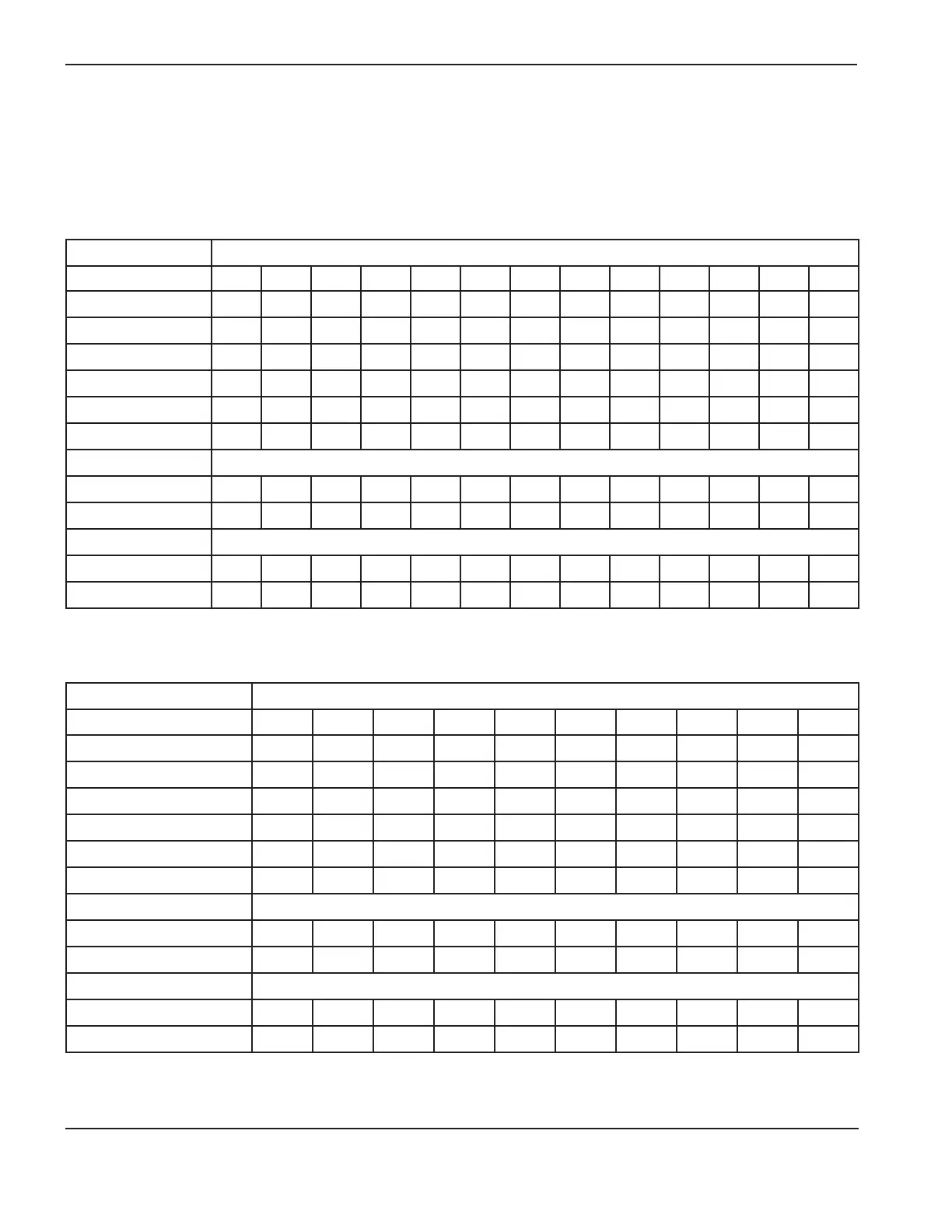

English

Process Thickness (in.)

Mild steel

0.135 0.25 0.375 0.5 0.625 0.75 1.0 1.25 1.5 2.0

50A O

2

/Air

0.059 0.064 ––––––––

50A Air/Air

0.051 0.053 ––––––––

130A O

2

/Air

0.096 0.105 0.114 0.123 0.132 0.141 0.159 – – –

130A Air/Air

0.089 0.095 0.102 0.109 0.116 0.123 0.138 – – –

200A O

2

/Air

– 0.110 0.119 0.128 0.136 0.145 0.163 0.180 0.197 0.232

200A Air/Air

– 0.106 0.115 0.124 0.132 0.141 0.159 0.177 0.195 0.231

Stainless steel

50A Air/Air 0.059 0.062 ––––––––

200A N

2

/Air – – 0.106 0.114 0.122 0.130 0.145 0.161 0.177 –

Aluminum

50A Air/Air 0.060 0.062 ––––––––

200A N

2

/Air – – 0.133 0.143 0.152 0.162 0.181 0.201 0.220 –

Loading...

Loading...