Installation, Operation, Repair And Parts Manual

7/05

Description

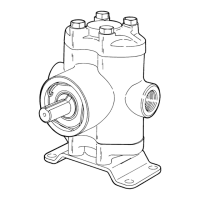

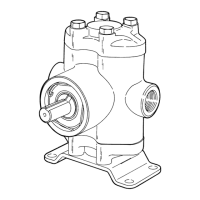

Series 5300C-X, 5321C, 5322C and 5324C

Small Twin

®

Piston and Plunger Pumps

Form L-0200P

The following special attention notices are used to notify

and advise the user of this product of procedures that

may be dangerous to the user or result in damage to the

product.

NO

TE: Notes are used to notify of installation, oper-

ation,

or maintenance inf

ormation that is impor

tant

but not safety related.

CA

UTION:

Caution is used to indicate the presence

of a hazar

d,

whic

h will or can cause minor injury or

property damage if the notice is ignored.

WARNING: Warning denotes that a potential hazard

exists and indicates procedures that must be fol-

lo

wed e

xactl

y to either eliminate or reduce the haz

-

ard, and to avoid serious personal injury, or prevent

future safety problems with the product.

D

ANGER:

Danger is used to indicate the presence

of a hazard that will result in severe personal injury,

death, or property damage if the notice is ignored.

Safety Information

SERIES 5321C & 5322C

Cast Iron Small Twin

Plunger Pump

Max. Flow Rate: ........................2.2 gpm

Max. Pressure: ........................1000 psi

Max. Speed: ............................1725 rpm

Ports:................................1/2" NPT inlet

1/2" NPT outlet

Max. Operating Temp. ................180

o

F

SERIES 5300C-X

Cast Iron Small Twin

Piston Pump

SERIES 5324C

Cast Iron Small Twin

Piston Pump

Max. Flow Rate: ........................2.9 gpm

Max. Pressure: ..........................800 psi

Max. Speed: ............................1725 rpm

Ports:................................1/2" NPT inlet

1/2" NPT outlet

Max. Operating Temp. ................140

o

F

Max. Flow Rate: ..................1.5, 2.0, 2.5

and 3.0 gpm

Max. Pressure: ..........................500 psi

Max. Speed: ............................1725 rpm

Ports:................................1/2" NPT inlet

1/2" NPT outlet

Max. Operating Temp. ................140

o

F

DANGER: DO NOT pump flammable or explosive

fluids such as gasoline, fuel oil, kerosene, etc. DO

NOT use in explosive atmospheres. The pump

should be used onl

y with liquids compatible with the

pump component materials. Failure to follow this

warning can result in personal injury and/or proper-

ty dama

g

e and will v

oid the pr

oduct warranty

.

A pressure relief device, such as an unloader, relief

valve or balancing regulator must be installed on the

outlet side of the pump.

F

ailure to do so could

result in per

sonal injur

y and/or v

oid the warranty

.

•

Be sure all exposed moving parts such as shafts,

couplers and adapters are properly shielded or

guarded and that all coupling de

vices are securely

attached before applying power.

• Hollo

w shaft pumps mounted directly onto po

w

er

shaft m

ust be pre

v

ented from rotating with the po

w

er

shaft by means of a device such as a torque arm.

Pump m

ust float freely on the po

wer shaft and must

not be tied r

igidly to equipment on which it is mount

-

ed.

AG_200P_0705.qxp 6/30/05 3:36 PM Page 1