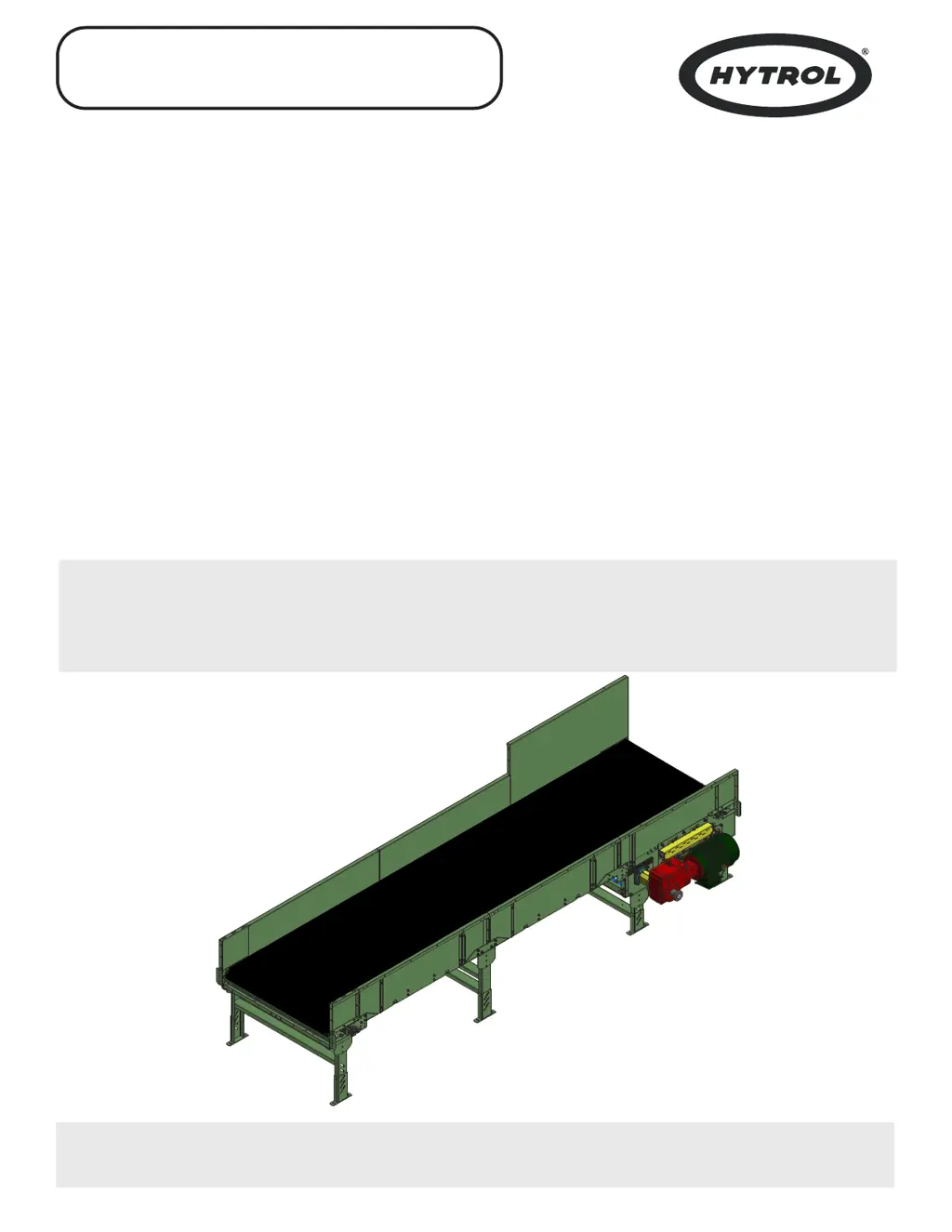

What to do if the belt slips on HYTROL HSS Accessories?

- CCarol DavisJul 31, 2025

If the belt slips or won’t move but the drive runs on your HYTROL Accessories, it could be due to a couple of reasons. First, the conveyor might be overloaded. Make sure to check the conveyor's capability and reduce the load to the recommended level. Alternatively, the belt might be too loose. In this case, slightly loosen the Take-Up, ensuring the pulley remains square in the frame.