Installation

When installing the element, check that the cleaner housing and element cover are completely in

close contact then tighten the nut.

Make sure that bottom cap are securely installed. If it is loosely installed, dust will

be drawn

in and air cleaner will fail to function properly.

When using compressed air, use safety glas

ses, face shield and other protective clothes.

Never point the air nozzle at anyone. Never clean or r

eplace air cleaner while engine is

running.

7-31

When remounting, connect the ground

connection last.

Do not allow tools to touch the (+) terminal

and the body

of the truck at the same time.

This can cause sparking and explosion.

Dispose of old battery in locall

y approved

manner.

Θ

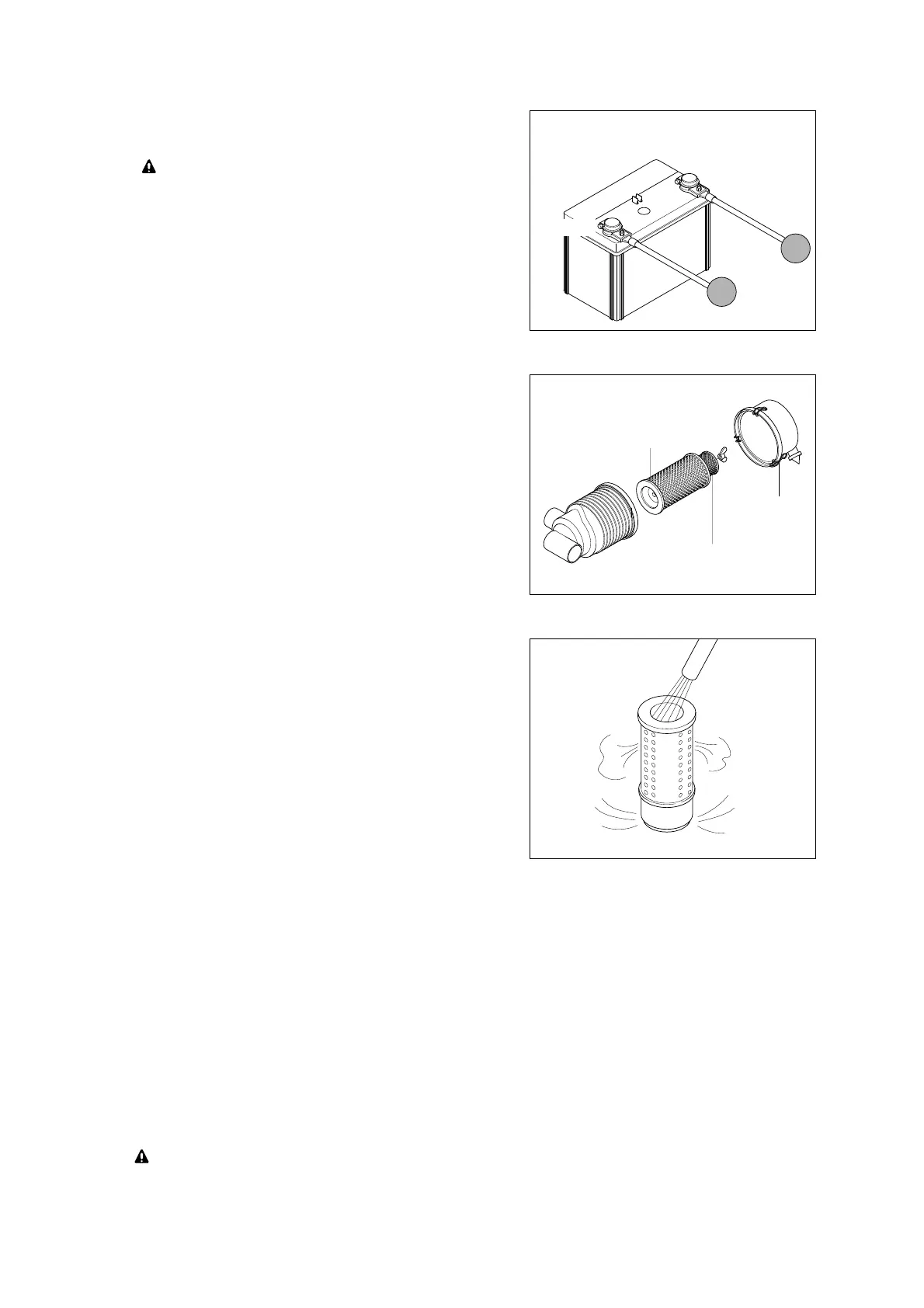

AAIR CLEANER ELEMENT

Removal

Double element type

Remove the cover by pulling off the clamps,

and loosen the wing nut to pull out the outer

element.

During periodic service, replace only the

outer element

. Do not replace the inner

element unless damaged.

2)

(1)

Η

ö

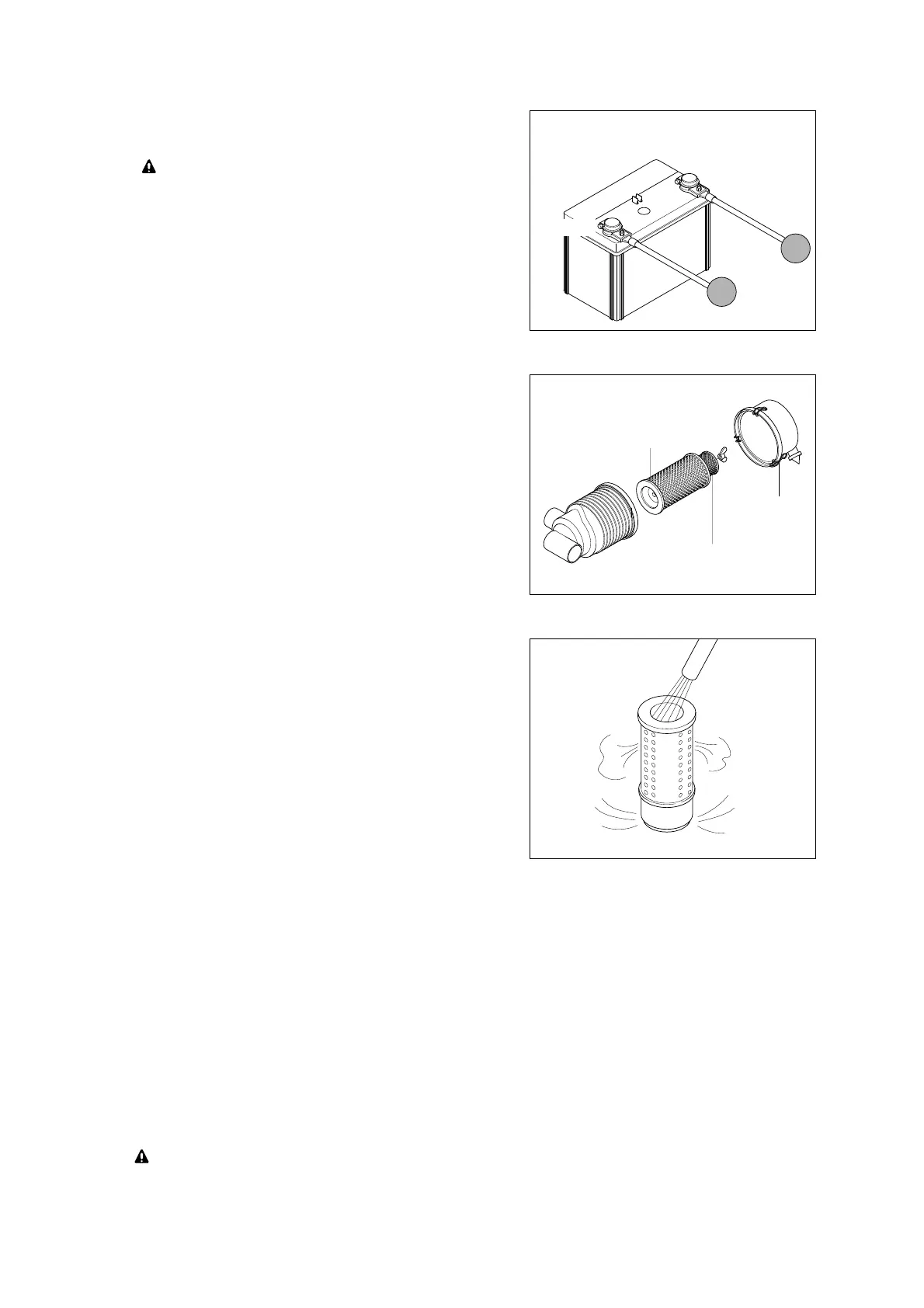

Cleaning

Cleaning with compressed air

Blow dry compressed air(Max 30

psi

) from inside

along pleats. Next blow air form outside along

pleats, then blow from inside again and check

element.

Cleaning with cleaning agent

If there is grease or carbon on the element, use

a special element cleaner, following the

instruction given with the cleaner. Have a spare

element ready so that the machine can start

working again immediately.

(2)

D155OM12

20DFOM26

D35AOM158

(3)

ö

Keep clean condition for the air cleaner element all the times.

A dirty air cleaner could be decreased output power of the engine at worst and it also will

be caused to increase fuel consumption and black smoke.

ΗΗ

Θ

ö

Loading...

Loading...