ACON, DCON List of Specifications

Item

Description

ACON-CA/CB/CGB DCON-CA/CB/CGB

Number of controlled axes 1-axis

Power-supply Voltage

24V DC 10%

Load

Capacity

(It does not

including

control side

current

consumption)

(Note1)

Series Motor Type

Rated

Max. Power

Consumption

MAX.

(Note5)

Rated MAX.

RCA,

RCA2,

RCL

2W 0.8A 4.6A

5W 1.0A 6.4A

10W

RCL

1.3A 6.4A

10W (RCA/ RCA2) 1.3A 2.5A 4.4A

20W 1.3A 2.5A 4.4A

20W

Model: 20S

1.7A 3.4A 5.1A

30W 1.3A 2.2A 4.0A

RCD 3W 0.7A 1.5A

Power Supply for Electromagnetic Brake

for actuator equipped with brake

24V DC 10% 0.15A (MAX.)

Heat Generation 8.4W 4W

Rush Curren

(Note2)

10A

Transient Power Cutoff Durability

MAX. 500s

Motor Control S

stem Sinusoidal Waveform

AC

Drive Rectan

ular Waveform

DC

Drive

Corresponding Encoder Incremental Encoder

Serial Absolute Encoder

Batter

-less Aboslute Encode

Incremental Encoder

Corresponding

Encoder

Resolution

RCA Incremental Type 800pulse/rev

Serial Absolute T

pe 16384pulse/rev

RCA2 RCA2_*** N 1048pulse/rev

Other than

RCA2_*** N

800pulse/rev

RCA

/RCA2

Batte

y-less

Absolute Type

16384pulse/rev

RCL RA1, RA4, SA1, SA4 715pulse/rev

RA2, RA5, SA2, SA5 855pulse/rev

RA3, RA6, SA3, SA6 1145pulse/rev

RCD

400pulse/rev

Actuator Cable Len

th MAX. 20m MAX. 10m

Serial Communication Interface

SIO Port

RS485 : 1 CH (based on Modbus Protocol RTU/ASCII) Speed : 9.6 to 230.4Kbps

Control available with serial communication in the modes other than the pulse train

External Interface PIO Type Signal I/O dedicated for 24V DC (selected from NPN/PNP) … Input 16 points max.,

output 16 points max. Cable len

th MAX. 10m

Fieldbus Type

DeviceNet, CC-Link, PROFIBUS-DP, CompoNet, MECHATROLINK-Ⅰ/Ⅱ,

EtherCAT, EtherNet/IP, PROFINET-IO, MECHATROLINK-Ⅲ (Except for ACON-CA

and DCON-CA

Data Settin

and Inpu

PC Software, Touch Panel Teachin

, Teachin

Pendant, Data Sette

Data Retention Memory Saves position data and parameters to non-volatile memory

There is no limitation to the number of times data ma

be written.

Operation Mode Positioner Mode/Pulse Train Control Mode

selected b

parameter settin

Number of Positions in Positioner Mode Standard 64 points, MAX. 512 points (PIO Type)

Note

Number of positions differs dependin

on the selection in PIO pattern.

Pulse Train

Interface

(Note4)

Input Pulse Frequency Differential System (Line Driver System) : MAX. 200kpps

Cable len

th MAX. 10m

Open Collector System : Not applicable.

* If the host applies the open collector output, prepare AK-04 (option) separately to

convert to the differential t

pe.

Command Pulse Multiplying

Factor (Electrical Gear : A/B)

1/50 A/B 50/1

Settin

Ran

e of A and B

set to parameter

: 1 to 4096

Feedback Pulse Output None

LED Display

(mounted on Front Panel)

SV (GN)/ALM (RD) : Servo ON/Alarm generated

STS0 to 3 : Status display

RDY (GN)/ALM (RD) : Absolute function in normal / absolute function error (for the simple

absolute type)

1, 0

GN

RD

: Absolute function status displa

for the simple absolute t

pe

Electromagnetic Brake Compulsory

Release Switch

mounted on Front Panel

Switching NOM (standard)/BK RLS (compulsory release)

Insulation Resistance

500V DC 10M or more

Protection Function a

ainst Electric Shoc

Class I basic insulation

Weight

(Note3)

(Other than

Field

Network

Type)

Incremental Type Screw fixed type : 230g or less

DIN rail fixed t

pe : 265

or less

Simple Absolute Type Battery (AB-7) : 190g or less

Absolute Battery Case (SEP-ABU):

140

or less

Serial Absolute T

pe Batter

AB-5

: 20

Coolin

Method Natural ai

-coolin

External dimensions Screw fixed t

pe : 35W×178.5H×69.6D DIN rail fixed t

pe : 35W×185H×78.1D

Environment

Surrounding Air Temperature

0 to 40C

Surroundin

Humidit

5%RH to 85%RH or less

There should be no condensation or freeze

Surroundin

Environmen

[Refer to Installation Environment]

Surrounding Storage

Temperature

-20 to 70C (Excluding battery)

Usa

e Altitude 1000m or less

Protection Class IP20

Vibration Durability Frequency 10 to 57Hz / Swing width : 0.075mm

Frequency 57 to 150Hz / Acceleration 9.8m/s

2

XYZ directions Sweep time : 10 minutes Number of sweep : 10 times

Note1 Control power capacity is 0.3A.

Note2 In-rush current will flow for approximately 5ms after the power is turned on (at 40C).

Note that the value of in-rush current differs depending on the impedance of the power supply line.

Note3 Add the weight of the battery (case) for “Simple Absolute Type” and “Serial Absolute Type”.

Note4 Serial absolute type is not applicable for the pulse train control mode.

Note5 The current reaches the maximum at the excitation phase detection of the motor conducted when the servo is turned on

for the first time after the power is supplied. (TYP 1 to 2 second, MAX. 10 second)

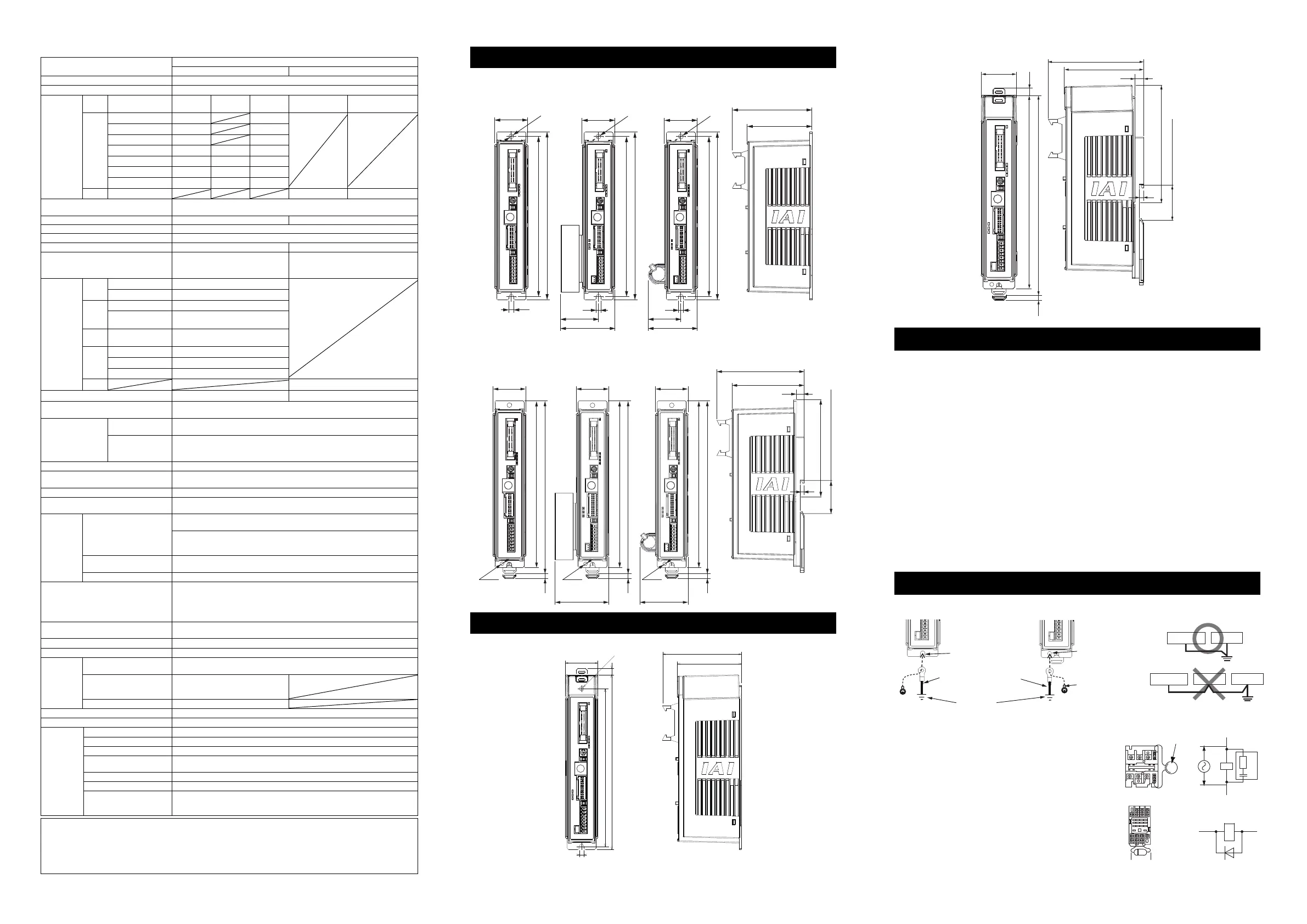

External Dimensions (ACON, DCON and PCON-CA/CB/CGB/CBP/CGBP)

● Screw fixed type

Battery-less Absolute/ Simplified Absolute Type Serial Absolute Type Side View

Incremental Type (Option) (Option)

84.8

69.6

35

φ

5

170.5

178.5

5

35

φ

5

5

(40.5)

(58)

170.5

178.5

35

φ

5

5

(34.5)

(52)

170.5

178.5

● DIN rail fixed type

Battery-less Absolute/ Simplified Absolute Type Serial Absolute Type Side View

Incremental Type (Option) (Option)

35

178.5

185

(5)

M3

(for FG cable

attachment)

93.6

78.1

8.5

4

104 from DIN rail center

35.4 (Width of 35mm DIN rail)

M3

35

178.5

185

(5)

(52)

(for FG cable

attachment)

M3

35

178.5

185

(5)

(58)

(for FG cable

attachment)

External Dimensions (PCON-CFA/CFB/CGFB)

● Screw fixed type

35

φ

5

5

84.8

69.6

190

170.5

(7)

(Note) When using the

attachment hole

on the top of the

controller, detach

the fan unit

temporarily.

● DIN rail fixed type

(7)

35

93.3

78.1

8.5

4

115 from DIN rail center

35.4 (Width of 35mm DIN rail)

190

(5)

196.5

Installation Environment

This product is capable for use in the environment of pollution degree 2

*1

or equivalent.

*1 Pollution Degree 2: Environment that may cause non-conductive pollution or transient conductive

pollution by frost (IEC60664-1)

1. Installation Environment

Do not use this product in the following environment

Location where the surrounding air temperature exceeds the range of 0 to 40C

Location where condensation occurs due to abrupt temperature changes

Location where relative humidity exceeds 5%RH to 85%RH

Location exposed to corrosive gases or combustible gases

Location exposed to significant amount of dust, salt or iron powder

Location subject to direct vibration or impact

Location exposed to direct sunlight

Location where the product may come in contact with water, oil or chemical droplets

Environment that blocks the air vent [Refer to Installation and Noise Elimination]

A place with its altitude more than 1000m

When using the product in any of the locations specified below, provide a sufficient shield.

Location subject to electrostatic noise

Location where high electrical or magnetic field is present

Location with the mains or power lines passing nearby

2. Storage and Preservation Environment

Storage and preservation environment follows the installation environment. Especially in a long-term storage, consider

to avoid condensation of surrounding air.

Unless specially specified, moisture absorbency protection is not included in the package when the machine is

delivered. In the case that the machine is to be preserved in an environment where dew condensation is anticipated,

take the condensation preventive measures from outside of the entire package, or directly after opening the package.

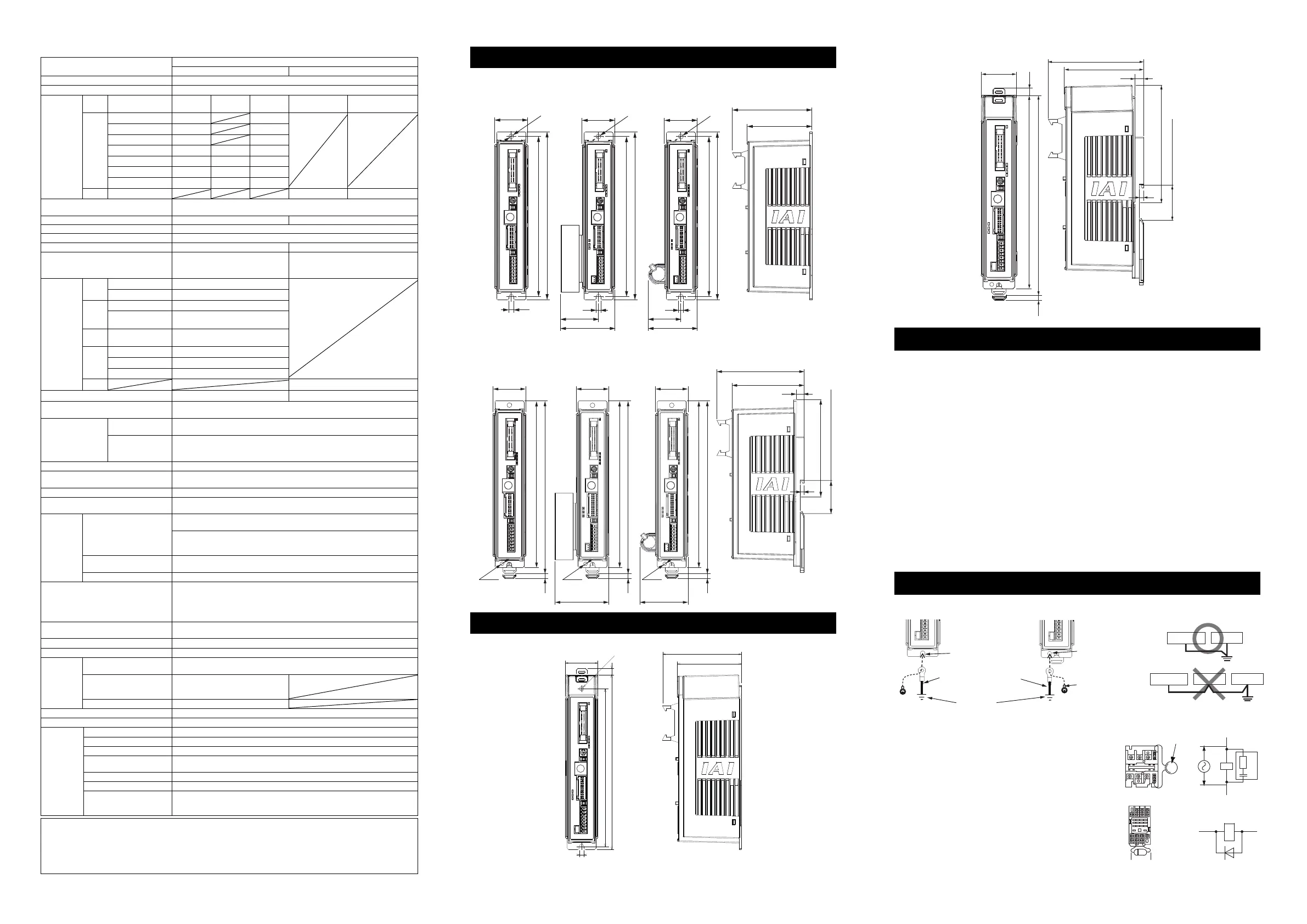

Installation and Noise Elimination

1. Noise Elimination Grounding (Frame Ground)

2. Precautions regarding wiring method

1) Wire is to be twisted for the 24V DC power supply.

2) Separate the signal and encoder lines from the power

supply and power lines.

3. Noise Sources and Elimination

Carry out noise elimination measures for power devices on

the same power path and in the same equipment.

The following are examples of measures to eliminate noise

sources.

1) AC solenoid valves, magnet switches and relays

[Measure] Install a Surge absorber parallel with the coil.

2) DC solenoid valves, magnet switches and relays

[Measure] Install a diode parallel with the coil. Use a DC

relay with a built-in diode.

Surge absorber

Relay

coil

Relay coil

R

C

+24V 0V

+24V 0V

+-

Do not share the ground wire with or connect

to other equipment. Ground each controller.

Controller

Other

equipment

Controller

Other

equipment

Other

equipment

Connect the ground cable

using the tapped hole for

FG connection on the main unit.

M3 × 5 nickeled pan head

machine screw

(enclosure dedicated for

DIN rail fixed type)

Screw fixed type DIN rail fixed type

Connect the ground line

together to the main unit

using the fixing screw.

Copper wire:

Connect a ground wire with a

diameter of 1.6mm (2mm

2

) or larger.

Earth Terminal

Grounding resistance 100Ω or less

(Class D grounding)

Loading...

Loading...