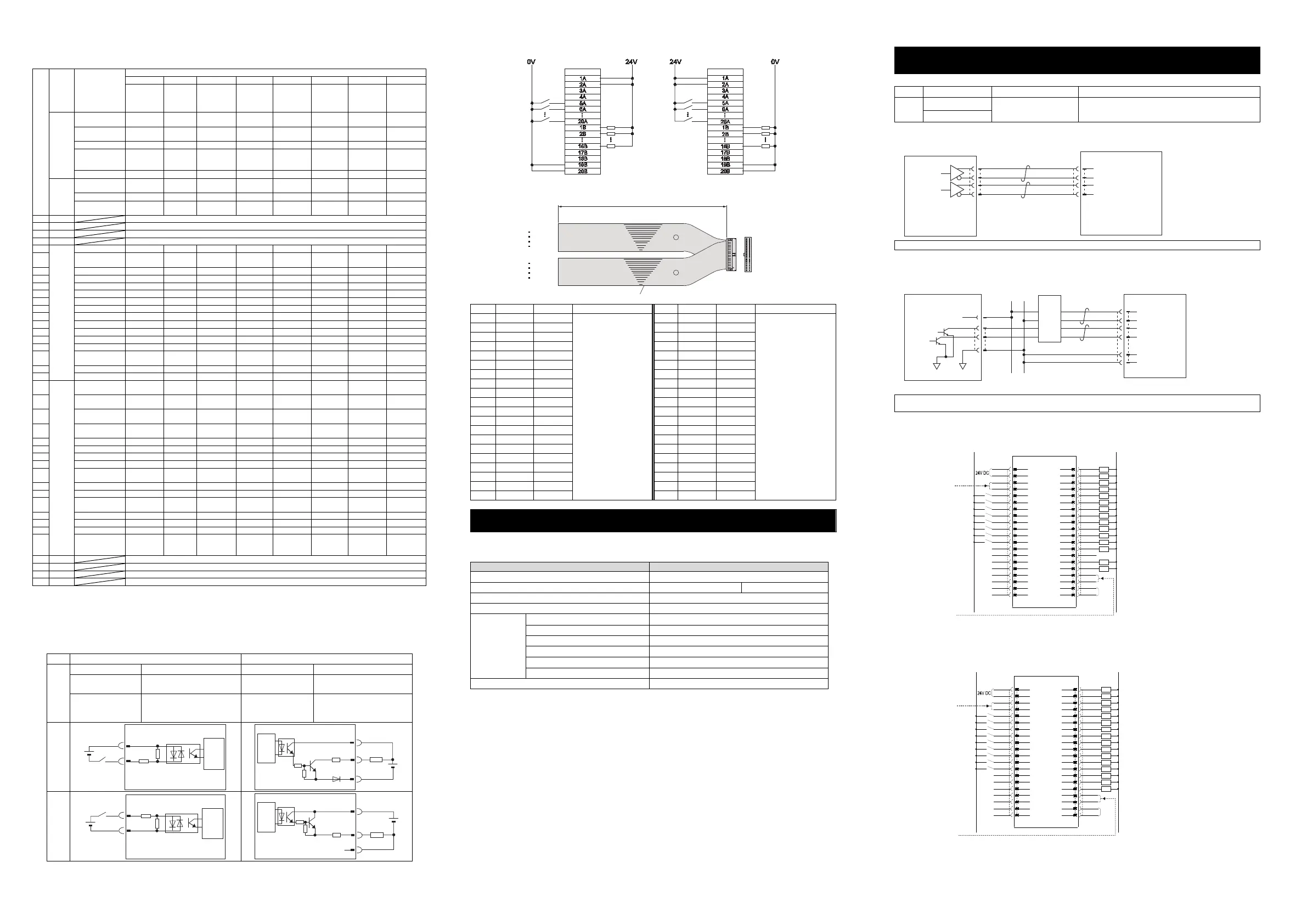

Signal Assignments in Each Mode

The signal assignment of I/O flat cable by the PIO pattern is as shown below. Follow the following table to connect the external

equipment (such as PLC).

Pin

No.

Category

PIO Functions

Selection in Parameter No. 25

PIO Pattern

0 1 2 3 4 5

6

(Note1)

7

(Note1)

Positioning

mode

Teaching

mode

256-point

mode

512-point

mode

Electro-

magnetic

valve mode

1

Electro-

magnetic

valve mode

2

Force

Sensor Used

Pressing

Mode 1

Force Sensor

Used

Pressing

Mode 2

Input

Number of

Positionin

Points

64 points 64 points 256 points 512 points 7 points 3 points 32 points 5 points

Home Return

Si

nal

Jog Signal

Teaching Signal

(Current Position

Writing)

Brake Release

Output

Signal during

Operation

Zone Signal

(Note2)

(Note2)

Position Zone

Si

nal

1A 24V P24

2A 24V P24

3

4

5A

Input

IN0 PC1 PC1 PC1 PC1 ST0 ST0 PC1 ST0

6A IN1 PC2 PC2 PC2 PC2 ST1

ST1

(JOG)

PC2 ST1

7A IN2 PC4 PC4 PC4 PC4 ST2

ST2

(Note2)

PC4 ST2

8

IN3 PC8 PC8 PC8 PC8 ST3

PC8 ST3

9

IN4 PC16 PC16 PC16 PC16 ST4

PC16 ST4

10A IN5 PC32 PC32 PC32 PC32 ST5 – – –

11A IN6 – MODE PC64 PC64 ST6 – – –

12

IN7

JISL PC128 P128

13A IN8 –

JOG

– PC256 – – CLBR CLBR

14A IN9 BKRL

JOG

BKRL BKRL BKRL BKRL BKRL BKRL

15

IN10 RMOD RMOD RMOD RMOD RMOD RMOD RMOD RMOD

16

IN11 HOME HOME HOME HOME HOME

HOME HOME

17A IN12 *STP *STP *STP *STP *STP – *STP *STP

18A IN13 CSTR

CSTR/PW

RT

CSTR CSTR – – CSTR –

19A IN14 RES RES RES RES RES RES RES RES

20

IN15 SON SON SON SON SON SON SON SON

1B

Output

OUT0

PM1

(ALM1)

PM1

(ALM1)

PM1

(ALM1)

PM1

(ALM1)

PE0 LS0

PM1

(ALM1)

PE0

2B OUT1

PM2

(ALM2)

PM2

(ALM2)

PM2

(ALM2)

PM2

(ALM2)

PE1

LS1

(TRQS)

PM2

(ALM2)

PE1

3B OUT2

PM4

(ALM4)

PM4

(ALM4)

PM4

(ALM4)

PM4

(ALM4)

PE2

LS2

(Note3)

PM4

(ALM4)

PE2

4B OUT3

PM8

ALM8

PM8

ALM8

PM8

ALM8

PM8

ALM8

PE3 –

PM8

ALM8

PE3

5B OUT4 PM16 PM16 PM16 PM16 PE4 – PM16 PE4

6B OUT5 PM32 PM32 PM32 PM32 PE5 – TRQS TRQS

7B OUT6 MOVE MOVE PM64 PM64 PE6

LOAD LOAD

8B OUT7 ZONE1 MODES PM128 PM128 ZONE1 ZONE1 CEND CEND

9B OUT8

PZONE/

ZONE2

PZONE/

ZONE1

PZONE/

ZONE1

PM256

PZONE/

ZONE2

PZONE/

ZONE2

PZONE/

ZONE2

PZONE/

ZONE2

10B OUT9 RMDS RMDS RMDS RMDS RMDS RMDS RMDS RMDS

11B OUT10 HEND HEND HEND HEND HEND HEND HEND HEND

12B OUT11 PEND

PEND/

WEND

PEND PEND PEND – PEND PEND

13B OUT12 SV SV SV SV SV SV SV SV

14B OUT13 *EMGS *EMGS *EMGS *EMGS *EMGS *EMGS *EMGS *EMGS

15B OUT14 *ALM *ALM *ALM *ALM *ALM *ALM *ALM *ALM

16B

OUT15

(Note3)

LOAD/TRQS

*ALML

/*BALM

*ALML

/*BALM

LOAD/TRQS

*ALML

/*BALM

LOAD/TRQS

*ALML

/*BALM

LOAD/TRQS

*ALML

/*BALM

*BALM/

*ALML

*ALML *ALML

17B

18B

19B 0V N

20B 0V N

(Note) “*” in codes above shows the signal of the active low.

PM1 to PM8 indicate the alarm binary code output signal when an alarm is generated. [Refer to the Instruction Manual

for the details]

(Note 1) PIO Patterns 6 and 7 should be available only when PCON-CBP/CGBP are ordered at purchasing.

(Note 2) The setting can be changed over to PZONE if set in the parameter setting.

(Note 3) It is invalid before home-return operation.

(Note 4) *BALM is dedicated for ACON.

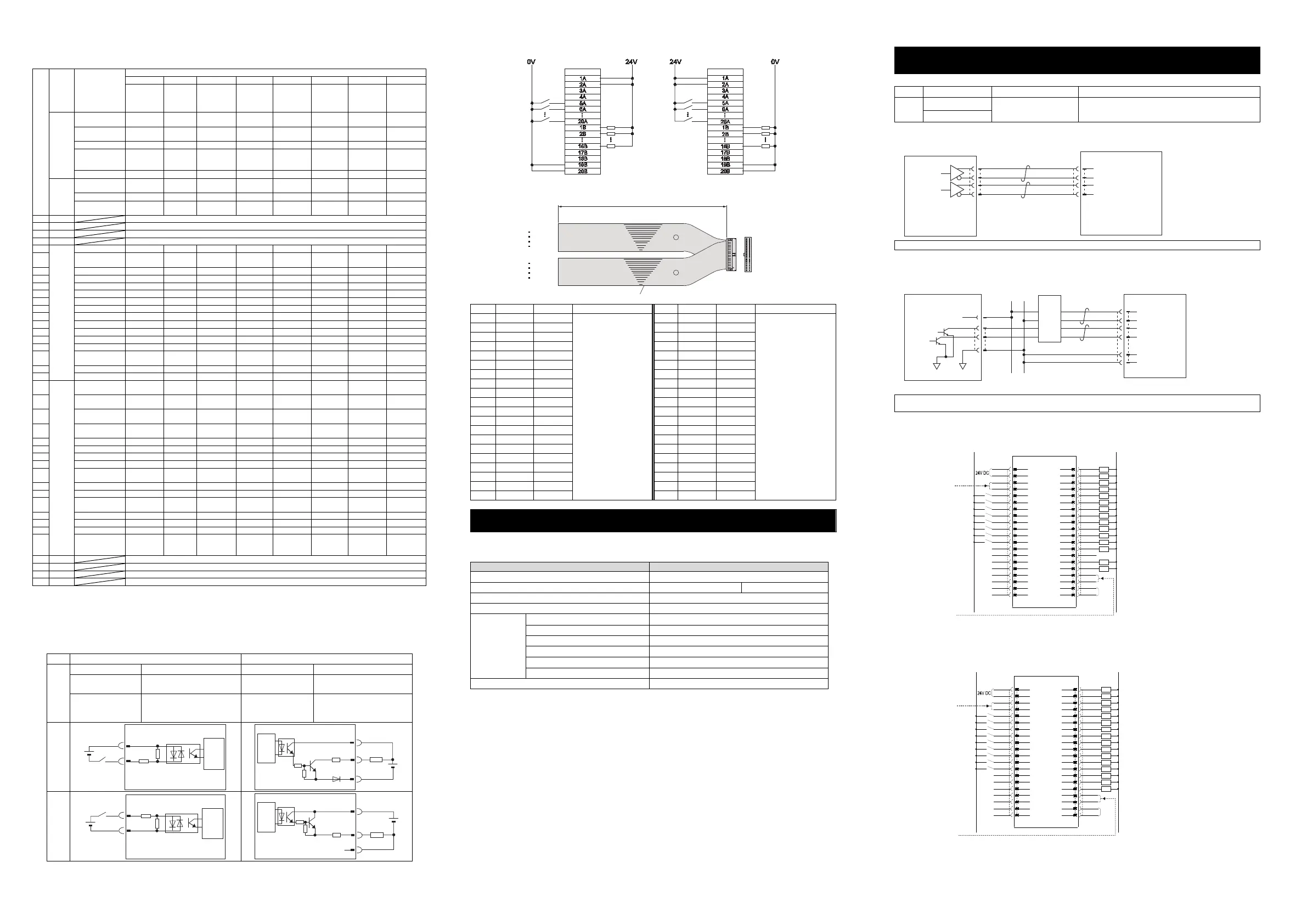

PIO Input and Output Interface

Input section Output section

Specification

Input voltage 24V DC10% Load voltage 24V DC

Input current 5mA 1 circuit

Peak load electric

current

50mA/1 point

ON/OFF voltage

ON voltage MIN. 18V DC

OFF voltage MAX. 6V DC

Leak Current

MAX. 2mA/1 point (PCON)

MAX. 1mA/1 point

(ACON, DCON)

NPN

680

5.6K

P24

External

Power Supply

24V DC

Input

Terminal

Internal

Power

Source

Controller

15

P24

N

Load

External

Power Supply

24V DC

Output

Terminal

Internal

Power

Source

Controller

PNP

680

5.6K

N

External

Power Supply

24V DC

Input

Terminal

Internal

Power

Source

Controller

15

P24

N

Load

External

Power Supply

24V DC

Output

Terminal

Internal

Power

Source

Controller

NPN Specification PNP Specification

I/O Cable

Model : CB-PAC-PIO□□□

(Enter the cable length (L) in □□□ Example. 020 2m)

No. Signal Name Cable Color Wiring No. Signal Name Cable Color Wiring

1A 24V BR-1

Flat Cable

○

A

(Insulation-Displacement

Connectors)

AWG28

1B OUT0 BR-3

Flat Cable

○

B

(Insulation-Displacement

Connectors)

AWG28

2A 24V RD-1 2B OUT1 RD-3

3A PP OR-1 3B OUT2 OR-3

4A /PP YW-1 4B OUT3 YW-3

5A IN0 GN-1 5B OUT4 GN-3

6A IN1 BL-1 6B OUT5 BL-3

7A IN2 PL-1 7B OUT6 PL-3

8A IN3 GY-1 8B OUT7 GY-3

9A IN4 WT-1 9B OUT8 WT-3

10A IN5 BK-1 10B OUT9 BK-3

11A IN6 BR-2 11B OUT10 BR-4

12A IN7 RD-2 12B OUT11 RD-4

13A IN8 OR-2 13B OUT12 OR-4

14A IN9 YW-2 14B OUT13 YW-4

15A IN10 GN-2 15B OUT14 GN-4

16A IN11 BL-2 16B OUT15 BL-4

17A IN12 PL-2 17B NP PL-4

18A IN13 GY-2 18B /NP GY-4

19A IN14 WT-2 19B 0V WT-4

20A IN15 BK-2 20B 0V BK-4

Loadcell (PCON-CBP/CGBP Dedicated Option)

It is a pressing force measurement unit used in the force control.

It should be used by connecting to an actuator applicable for the force control or servo pressing.

[Specification]

Item S

ecification

Loadcell System Strain Gauge

Rated Capacity [N] 600 2000

Total Accuracy [% F.S.] ±1

Allowable Overload [% F.S.] 200

Environmental

Specifications

Surrounding Air Temperature

0 to 40 C

Surrounding Humidity

85%RH o

less (non-condensing)

Surrounding Environment

Should be no corrosive gas

Surrounding Storage Temperature

-10 to 60 C

Ambient Humidity for Storage

90%RH less (non-condensing)

Vibration Resistance

10 to 57Hz in X, Y and Z di

ections

Dielectric Withstanding Voltage [V] DC50V

* F.S.(Withstand Load)

Note The number of actuators available to connect should differ depending on the rated capacity of a loadcell.

[Check in an instruction manual of an actuator for how to install and details of dimensions.]

Operation in Pulse Train Control Mode

function for PLN and PLP T

pes onl

Pulse Train Input and Output Interface

Categor

Abbreviated Code Signal Name Contents of Functions

Input

PP, /PP

Command Pulse Input

Inputs the command pulse train.

Input pulse frequency differs depending on the type.

[Refer to Basic Specifications]

NP, /NP

● When Host Unit is Differential System

(Although the example shows PCON, it is the same for ACON and DCON.)

Note1 : Use the same power source (0V) for the host open collector output, AK-04.

● When Host Unit is Open Collector System [AK-04 (option) is required]

(Although the example shows PCON, it is the same for ACON and DCON.)

Note1 : 1) Use the same power source (0V) for the host open collector output, AK-04.

2) Have the cables as short as possible between the host unit and AK-04.

PIO Pattern 6 ... Pulse Train Control Mode (for incremental type actuators)

PIO Pattern 7 ... Pulse Train Control Mode (for Absolute type actuators)

* shows a signal in active low. The input signal should be processed when it turns off, and the output signal should ordinary be

on while the power is turned on and turns off when the signal gets output.

Pin No.

Pin No.

Load

Load

Flat Cable (20-core)

×

2

BK-4

BR-3

BK-2

BR-1

No treatment

conducted

No treatment

conducted

20A 20B

1A 1B

Half Pitch MIL Socket

HIF6-40D-1.27R (Hirose Electric)

A

B

L

0V

24V

DC

0V

0V

1

2

3

4

1

2

3

4

PCON

PIO Connector

3A

4A

17B

18B

19B

20B

Host Unit

Positioning Unit

Pulse

Command

0V

0V

PP

/PP

NP

/NP

/PP

PP

NP

/NP

NP

PP

0V

24V

Pulse Converter

AK-04

(to be purchased separately)

24V

PCON

PIO Connector

3A

4A

17B

18B

Host Unit

Positioning Unit

Pulse Command

(Line Driver:

26C31 or equiv.)

PP

/PP

NP

/NP

0V

NPN T

pe

BR- 1

1A

P24

PWR

1B

BR- 3

0V

24V DC(NPN Type)

24V DC(PNP Type)

RD- 1

2A

P24 SV

2B

RD- 3

0V(PNP Type)

OR- 1

3A

SON

INP

3B

OR- 3

System Ready

YW- 1

4A

RES

HEND

4B

YW- 3

Servo ON Status

GN- 1

5A

HOME

TLR

5B

GN- 3

BL- 1

6A

TL

6B

BL- 3

PL- 1

7A

CSTP

7B

PL- 3

Deviation Counter Clear

GY- 1

8A

DCLR

8B

GY- 3

Brake Control Release

Compulsory Stop

Torque Limit Select

WT- 1

9A

BKRL

ZONE1

ZONE2

9B

WT- 3

Operation Mode

BK- 1

10A

RMOD

RMDS

10B

BK- 3

Zone 2

Zone 1

Home Return

BR- 2

11A

ALM1

ALM2

ALM4

ALM8

11B

BR- 4

RD- 2

12A

12B

RD- 4

Operating Mode Status

Emergency Stop Status

OR- 2

13A

13B

OR- 4

Home Return Completion

Torque Under Control

Reset

YW- 2

14A

*EMGS

14B

YW- 4

Position Completion

Servo ON

GN- 2

15A

*ALM

15B

GN- 4

BL- 2

16A 16B

BL- 4

PL- 2

17A

N

17B

PL- 4

Alarm Code Output 1

Alarm

Alarm Code Output 2

Alarm Code Output 4

Alarm Code Output 8

GY- 2

18A

N

18B

GY- 4

WT- 2

19A

19B

WT- 4

BK- 2

20A

20B

BK- 4

PCON

PIO Connector

NC/*ALML

None/Light Error Alarm Output

PP

/PP

NP

/NP

Differential Pulse Supply

[Refer to the next page for

the details of wiring.]

Differential Pulse Supply

[Refer to the next page for

the details of wiring.]

0V

NPN T

pe

BR- 1

1A

P24

PWR

1B

BR- 3

0V

24V DC(NPN Type)

24V DC(PNP Type)

RD- 1

2A

P24 SV

2B

RD- 3

0V(PNP Type)

OR- 1

3A

SON

INP

3B

OR- 3

System Ready

YW- 1

4A

RES

HEND

4B

YW- 3

Servo ON Status

GN- 1

5A

HOME

TLR

5B

GN- 3

BL- 1

6A

TL

6B

BL- 3

PL- 1

7A

CSTP

7B

PL- 3

Deviation Counter Clear

GY- 1

8A

DCLR

8B

GY- 3

Brake Control Release

Compulsory Stop

Torque Limit Select

WT- 1

9A

BKRL

ZONE1

REND

ZONE2

9B

WT- 3

Operation Mode

Datum Position Movement Command

BK- 1

10A

RMOD

RSTR

RMDS

10B

BK- 3

Zone 2

Zone 1

Home Return

BR- 2

11A

ALM1

ALM2

ALM4

ALM8

11B

BR- 4

RD- 2

12A

12B

RD- 4

Operating Mode Status

Emergency Stop Status

OR- 2

13A

13B

OR- 4

Home Return Completion

Torque Under Control

Reset

YW- 2

14A

*EMGS

14B

YW- 4

Position Completion

Servo ON

GN- 2

15A

*ALM

15B

GN- 4

BL- 2

16A 16B

BL- 4

PL- 2

17A

N

17B

PL- 4

Alarm Code Output 1

Alarm

Alarm Code Output 2

Alarm Code Output 4

Alarm Code Output 8

GY- 2

18A

N

18B

GY- 4

WT- 2

19A

19B

WT- 4

BK- 2

20A

20B

BK- 4

ACON, DCON

PIO Connector

NC/*ALML

None/Light Error Alarm Output

Datum Position Movement Complete

PP

/PP

NP

/NP

Differential Pulse Supply

[Refer to the next page for

the details of wiring.]

Differential Pulse Supply

[Refer to the next page for

the details of wiring.]

Loading...

Loading...