For PPs material, use the 6" transition / adaptor fitting (Sch 40 to PPs) offered by the respective PPs

manufacturers Centrotherm / InnoflueTM (their part # ISAAL0606) or M&G Dura Vent / PolyProTM (#

6PPS-06PVCM-6PPF [10004281]), (# 4PPs-AD). For PPs material exposed to outdoor weather, follow

the venting supplier’s recommendations on UV protection.

For SS material, use the 6" transition / adaptor fitting offered by the SS manufacturers M&G Dura Vent (#

FSA-6PVCM-6FNSF [300538]) or Heat Fab (Saf-T-Vent) 9601PVC.

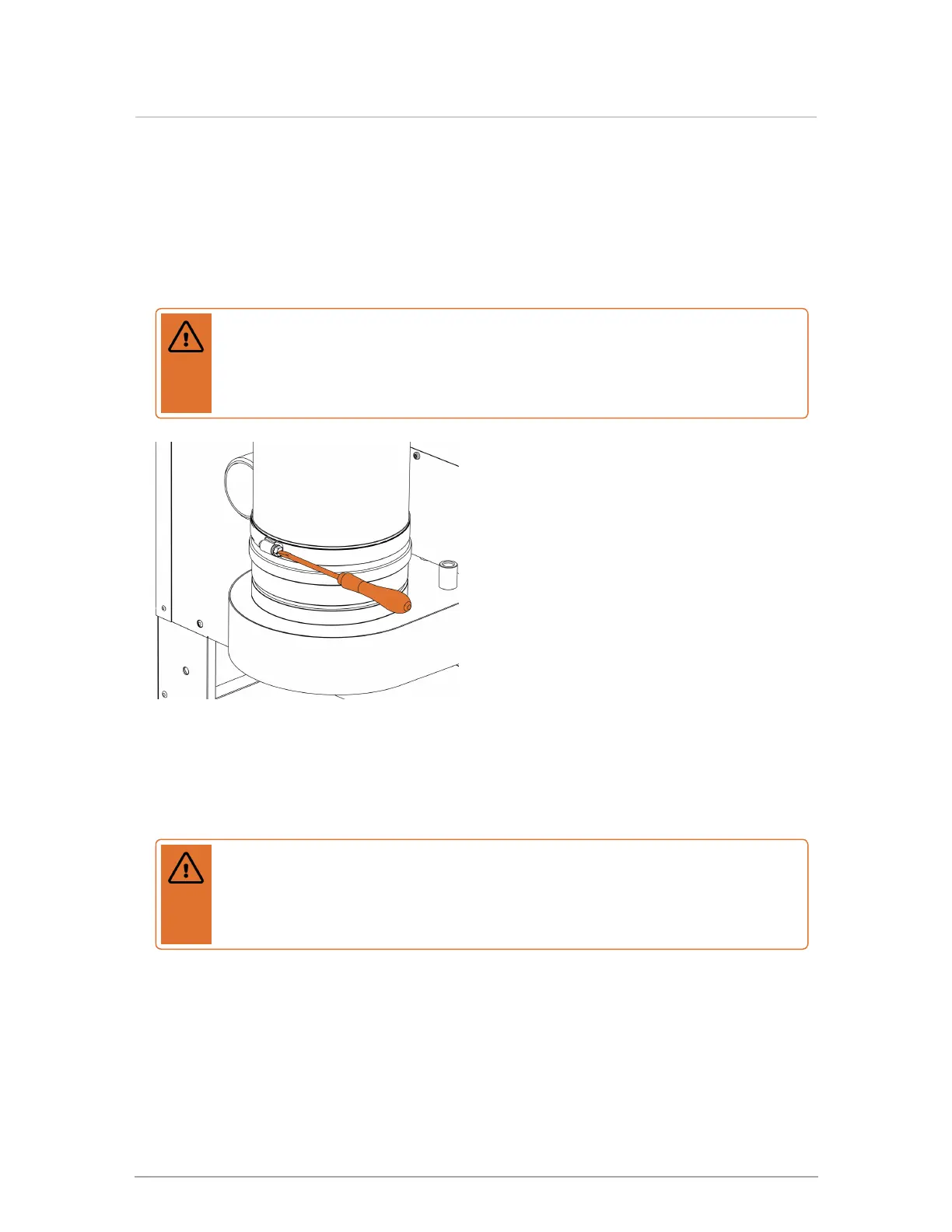

Warning

Ensure that you lubricate the gasket with silicone grease before inserting the venting

material. Fully insert the approved venting material into the boiler's exhaust outlet, and

tighten clamp to ensure the venting connection is locked in place (as shown below).

Figure 8 Securing the vent connection

Venting must be supported in accordance with the applicable code and instructions supplied by the

manufacturers.

Warning

Do not mix PPs venting materials from different manufacturers. These venting materials are

designed to be installed as part of a complete system. Failure to comply may result in severe

personal injury or death.

3.5.4 Vent travel

PVC/CPVC (Schedule 40), PPs (Rigid Single Wall), or SS approved piping are the standard venting

options that can be sited up to 120 equivalent feet from the vent termination.

Loading...

Loading...