Combustion testing and adjustment

Danger

Acombustiontestchecksthatthegasvalveisoperatingproperlyinthefield.Toperformacombustiontest,you

mustbeaqualified,trainedandlicensedgasfitter.

Makingadjustmentstothegasvalvewithoutaproperlycalibratedgascombustionanalyzerandbypeoplewho

arenottrainedandexperiencedinitsuseisforbidden.Failuretouseananalyzercanresultinanimmediate

hazard.

Model Number High Fire Input

SFC-199

125MBH(onaheavyload,only

DHWprovidesfullinputof199

BTUs)

Table 3 - Rated input of a converted appliance

Normalignitionsystemsequenceofoperation:

Theappliance'scontrol,uponacallforDHW,turnsonthecombustionfanforashortpre-purge,thenenergizesthespark

electrodeandgasvalvefora5-secondtrialforignition.

Iftheburnerdoesnotlight,theprocessisrepeateduntiltheburnerlightsandflameisdetected.After4unsuccessfultrials

forignition,theappliancelocksoutandwillneedtobemanuallyresetbypressingtheReturnArrow button.

To perform a combustion test and adjustment:

1. Turnofftheappliance’sgasshut-offvalve.

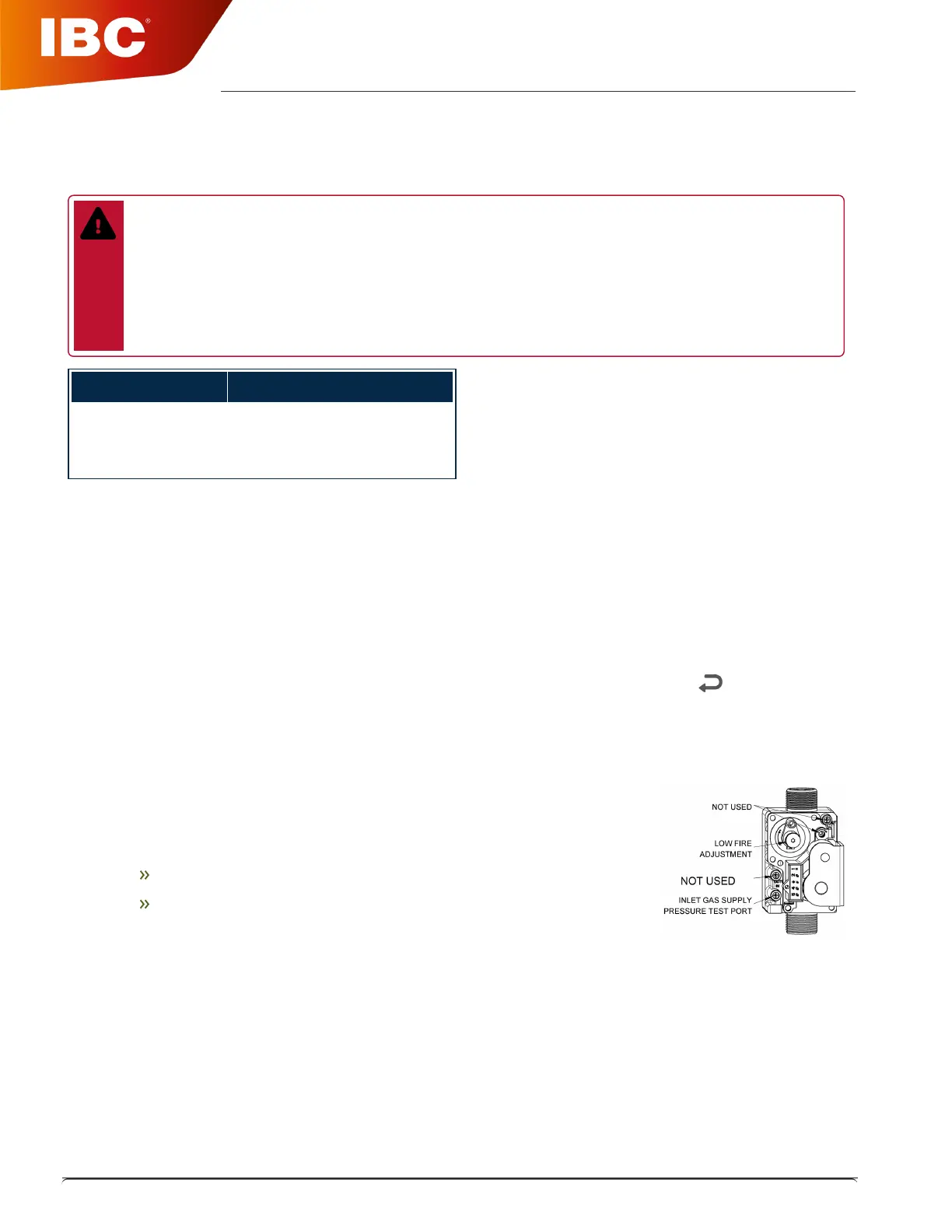

2. Withasmallflatscrewdriver(1/8"or3mm),opentheinletgassupplypressuretest

portbyturningitsscrew1fullturncounterclockwise.

3. Attachamanometertotheinletpressuretestportandturnongastoappliance.

Staticmanometerreadingshouldbeideally11"w.c.forpropane.

Minimumandmaximumstaticpressuremustbebetween5"and14"w.c.

Monitorpressurethroughoutthecommissioning(start-up)procedure.

Pressuremaydroopupto1"w.c.athighfire.

4. Tosettheappliancetohighfiremanually,createalargedemandbyturningupallthethermostatsorcreatealarge

DHWdemandfortheappliancetoheat.

Note:AllowtheappliancetooperateatHighFirefor3minutestostabilize.(Theapplianceoperatesinmanual

modefor10minutesthenswitchbacktothenormaloperatingmode.Toextendmanualmodeoperation,pressthe

Service andPlusbuttonstogethertwicewhiletheapplianceisoperatinginmanualmodetoresetthetimerfor10

Loading...

Loading...