3-3

STARTUP AND COMMISSIONING

VFC 15-150, VFC 45-225 MODULATING GAS BOILERS

procedure. Pressure may droop up to 1” to 2” w.c. at high re but under no

circumstances should it drop below 3” w.c. at the gas valve inlet test port.

2. Allow the boiler to ignite / run against a large load, to maintain high re

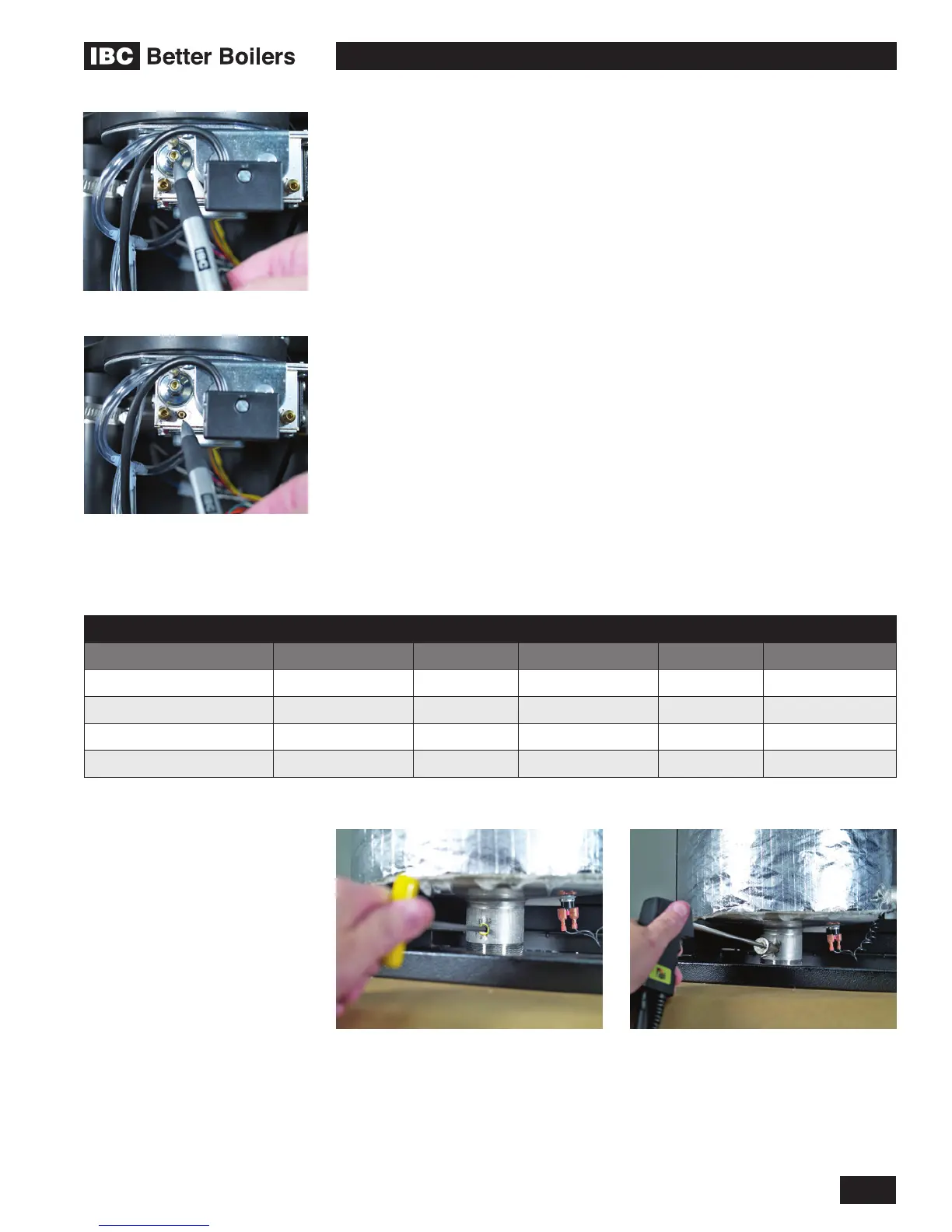

3. With the boiler at maximum output, use a 2 mm hex key to adjust the zero-

offset (see Figure 32, “A”) as required to achieve -0.2 to -0.3” wc. This

adjustment should only be necessary if this screw has been tampered with.

4. With a combustion analyzer probe in the ue gas test port, turn the Gas:Air

Ratio Adjustment screw (see Figure 32, “B”) to achieve the appropriate Table

8 mixture target at High Fire. This screw offers very ne adjustment, and

may require several turns. NOTE: This screw has signicant backlash. When

changing direction of turn, it may take up to a full turn before any change

is indicated on the analyzer reading. Clock the gas meter to conrm full

maximum rating plate input.

5. To conrm or adjust the minimum re level settings, Re-dene the load as

“Manual Control”. Use Heat Output in “Congure Load x” to control the output

as needed.

6. At the minimum ring rate, adjust the zero-offset screw (see Figure 32, “A”)

to obtain the target CO

2

value. It may be necessary to reduce the output in

stages if this adjustment has been tampered with.

7. Turn boiler off by removing the call for heat (use the Heat Load Conguration

screen to turn load to off if no other ready means available); turn OFF gas

supply to boiler, then remove the manometer connections, and turn the

centre-screw in the manifold pressure test port 1 full turn clockwise. Ensure

fully closed, but not over-tightened. Restore gas and soap test for leaks.

Zero-offset adjustment screw

Gas:Air ratio adjustment screw

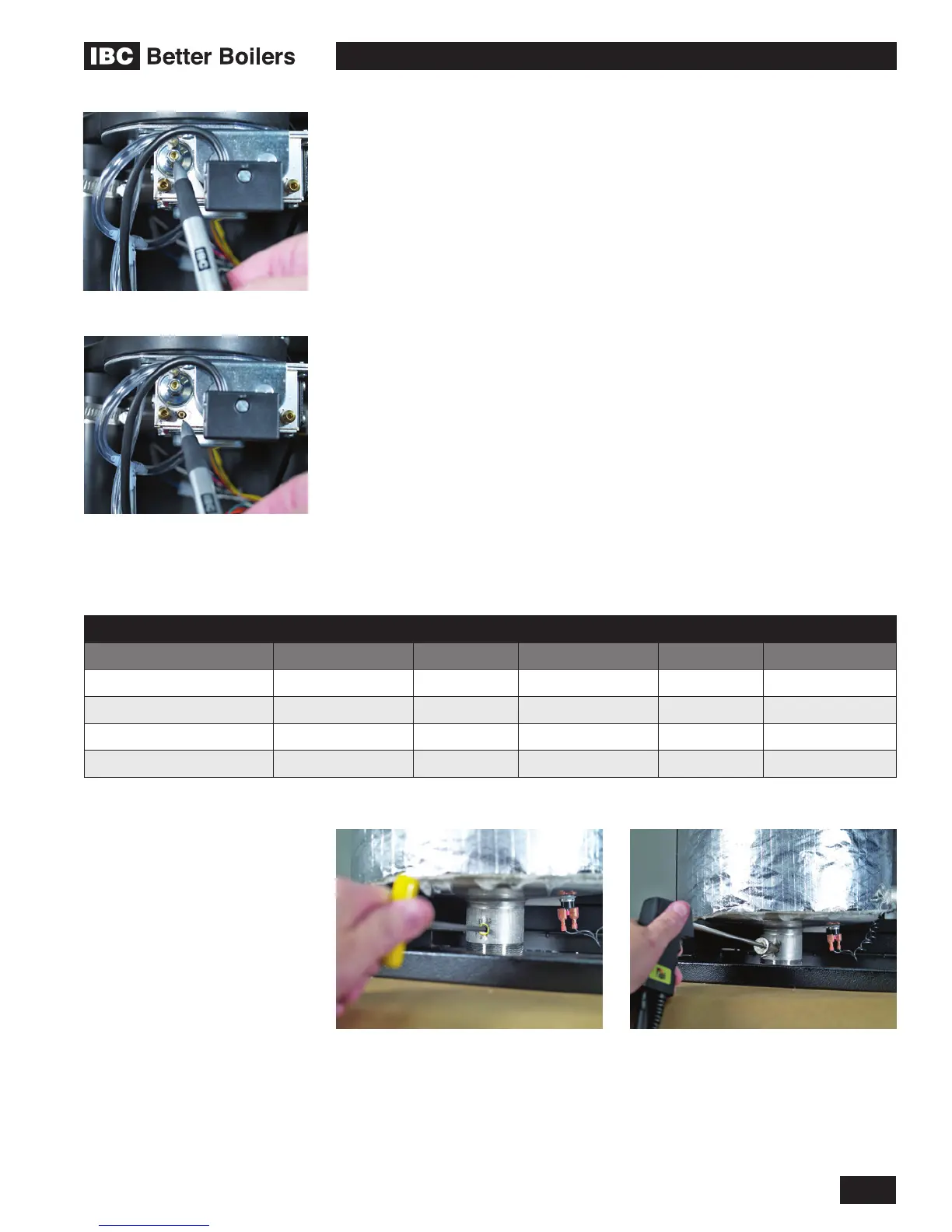

Insertion of ue gas analyzer probeRemoval of ue gas test port plug

MODEL HIGH FIRE LOW FIRE CO MAX PPM

RANGE TARGET RANGE TARGET

VFC 15-150 (Natural Gas) 8.9 to 9.5% CO

2

9.2% CO

2

7.9 to 8.6% CO

2

8.4% CO

2

< 100

VFC 15-150 (Propane) 10.4 to 10.7% CO

2

10.6% CO

2

9.0 to 9.8% CO

2

9.6% CO

2

< 150

VFC 45-225 (Natural Gas) 8.9 to 9.5% CO

2

9.2% CO

2

7.9 to 8.6% CO

2

8.4% CO

2

< 120

VFC 45-225 (Propane) 10.4 to 10.7% CO

2

10.6% CO

2

9.0 to 9.8% CO

2

9.6% CO

2

< 180

Table 8: Combustion test target ranges - CO

2

/ Maximum CO

Loading...

Loading...