441 01 2314 06

Specifications are subject to change without notice.

9

3. Other openings are caulked or sealed. These include

joints around window and door frames, between sole

plates and floors, between wall−ceiling joints, between

wall panels, at penetrations for plumbing, electrical and

gas lines, etc.

Ventilation Air

Some provincial codes and local municipalities require ventilation

or make−up air be brought into the conditioned space as replace-

ment air. Whichever method is used, the mixed return air tempera-

ture across the heat exchanger MUST not fall below 60° F(16° C)

continuously, or 55° F(13° C) on an intermittent basis so that flue

gases will not condense excessively in the heat exchanger. Ex-

cessive condensation will shorten the life of the heat exchanger

and possibly void your warranty.

4. Gas Vent Installation

CARBON MONOXIDE POISONING, FIRE AND

EXPLOSION HAZARD

Failure to follow this warning could result in

personal injury, death and/or property damage.

Read and follow all instructions in this section.

!

WARNING

Install the vent in compliance with codes of the country having ju-

risdiction, local codes or ordinances and these instructions.

This Category I furnace is fan−assisted. A fan assisted appliance

is an appliance equipped with an integral mechanical means to ei-

ther draw or force products of combustion through the heat ex-

changer.

Category I furnace definition: A central furnace which operates

with a non−positive vent static pressure and with a flue loss not

less than 17 percent. These furnaces are approved for common−

venting and multi−story venting with other fan−assisted or draft

hood−equipped appliances in accordance with the NFGC or

NSCNGPIC.

Category I Safe Venting Requirements

Category I furnace vent installations shall be in accordance with

Parts 10 and 13 of the National Fuel Gas Code, ANSI

Z223.1/NFPA 54−2009; and/or Section 8 and Appendix C of the

CSA B149.1−05, National Standard of Canada, Natural Gas and

Propane Installation Code; the local building codes; furnace and

vent manufacturer’s instructions.

NOTE: The following instructions comply with the ANSI

Z223.1/NFPA 54 National Fuel Gas Code and CSA B149.1 Natu-

ral Gas and Propane Installation code, based on the input rate on

the furnace rating plate.

1. If a Category I vent passes through an attic, any concealed

space or floor, use ONLY Type B or Type L double wall vent

pipe. If vent pipe passes through interior wall, use Type B vent

pipe with ventilated thimble ONLY.

2. Do NOT vent furnace into any chimney serving an open fire-

place or solid fuel burning appliance.

3. Use the same diameter Category I connector or pipe as per-

mitted by:

• the National Fuel Gas Code Code ANSI Z223.1/NFPA

54−2009 Sections 12 and 13 venting requirements in the

United States,

or

• the National Standard of Canada Natural Gas and Pro-

pane Installation Code (NSCNGPIC) CSA B149.1−05

Section 8 and appendix C venting requirements in Cana-

da.

4. Push the vent connector onto the furnace flue collar of the

venter assembly until it touches the bead [at least

5

/

8

″

(15.9mm) overlap] and fasten with at least two field−supplied,

corrosion−resistant, sheet metal screws located at least 140°

apart.

5. Keep vertical Category I vent pipe or vent connector runs as

short and direct as possible.

6. Vertical outdoor runs of Type−B or ANY single wall vent pipe

below the roof line are NOT permitted.

7. Slope all horizontal runs up from furnace to the vent terminal a

minimum of

1

/

4

″ per foot (10mm/m)

8. Rigidly support all horizontal portions of the venting system ev-

ery 6′ (1.8m) or less using proper clamps and metal straps to

prevent sagging and ensure there is no movement after instal-

lation.

9. Check existing gas vent or chimney to ensure they meet clear-

ances and local codes. See Figure 1

10. The furnace MUST be connected to a factory built chimney or

vent complying with a recognized standard, or a masonry or

concrete chimney lined with a lining material acceptable to the

authority having jurisdiction. Venting into an unlined ma-

sonry chimney or concrete chimney is prohibited. See the

Masonry Chimney Venting section in these instructions.

11. Fan−assisted combustion system Category I furnaces shall

not be vented into single−wall metal vents.

12. Category I furnaces must be vented vertically or nearly verti-

cally, unless equipped with a listed mechanical venter.

13. Vent connectors serving Category I furnaces shall not be con-

nected into any portion of mechanical draft systems operating

under positive pressure.

A 4−to−3 inch (101.6−to−76.2mm) reducer is permitted at the flue

collar when installing a 50,000 BTUH (14.5 kW) gas input furnace,

if the installation meets all the following requirements for sizing the

vent connectors and vents:

1. The National Fuel Gas Code, ANSI

Z223.1/NFPA−54−2009, Sections 12.6.3.1(1),

12.7.3.1(2), 12.11.3.1, 13.1.2, 13.1 (e), and 13.2.24(1)

through (3) in the U.S. or

2. The Natural Gas and Propane Installation Code CSA

B149.1−05, Sections 8.13.1(b), 8.13.2(b), 8.18.5(b), and

Appendix C−GVR no. 2. in Canada.

Venting and Combustion Air Check

NOTE: When an existing Category I furnace is removed or re-

placed, the original venting system may no longer be sized to prop-

erly vent the attached appliances, and to make sure there is

adequate combustion air for all appliances, MAKE THE FOL-

LOWING CHECK.

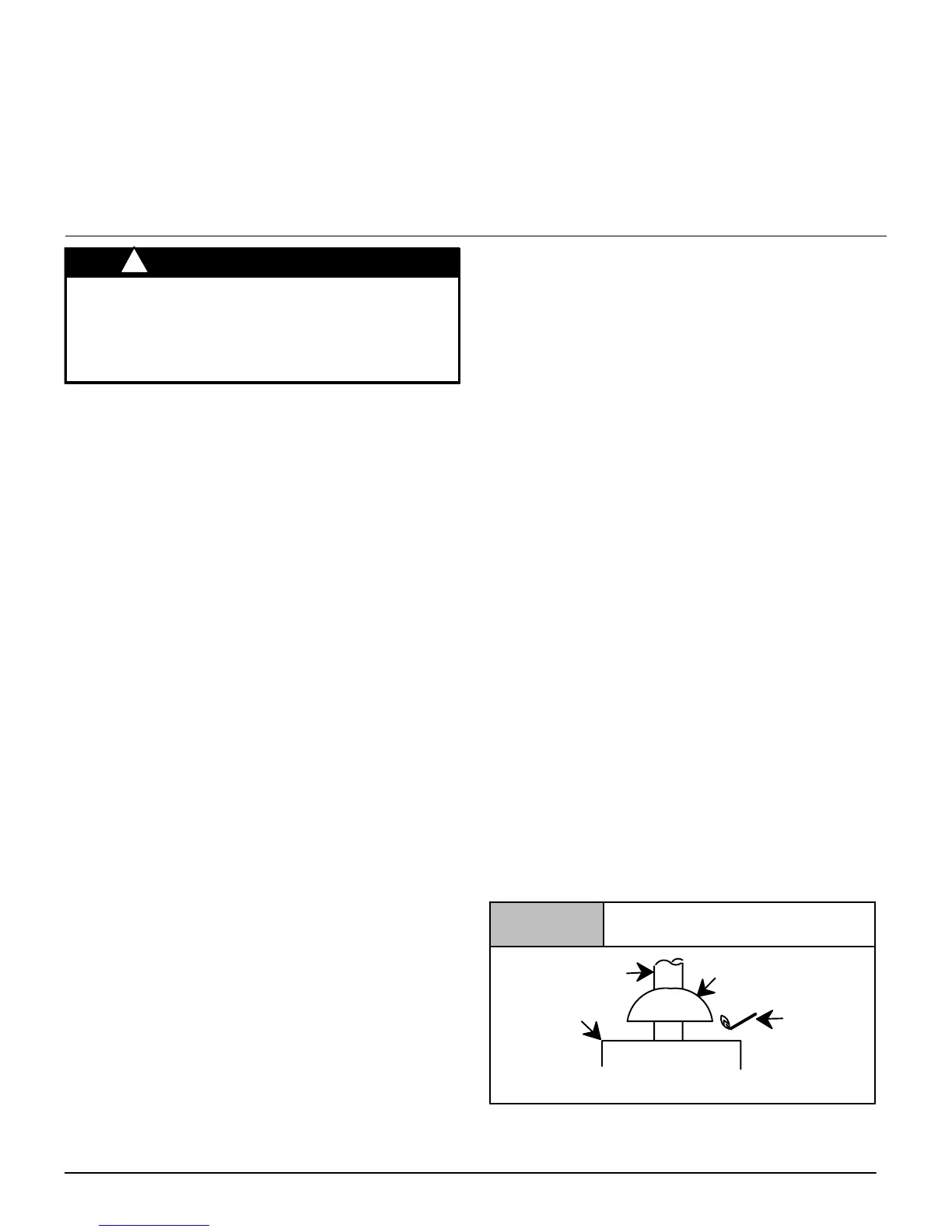

Vent Check

Draft HoodVent Pipe

Match

Typical Gas

Water Heater

Figure 4

NOTE: If flame pulls towards draft hood, this indicates

sufficient infiltration air.

Loading...

Loading...