Printed in U.S.A. 440 04 4321 04 July 2012

SERVICE AND TECHNICAL

SUPPORT MANUAL

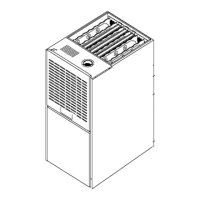

Two−Stage, ECM Blower Motor

35” Tall, High Efficiency Condensing Gas Furnace

(F/G)9MXT

Save this manual for future reference.

Safety Labeling and Signal Words

DANGER, WARNING, CAUTION, and NOTE

The signal words DANGER, WARNING,

CAUTION, and NOTE are used to identify levels of

hazard seriousness. The signal word DANGER is

only used on product labels to signify an immediate

hazard. The signal words WARNING, CAUTION,

and NOTE will be used on product labels and

throughout this manual and other manual that may

apply to the product.

DANGER − Immediate hazards which will result in

severe personal injury or death.

WARNING − Hazards or unsafe practices which

could result in severe personal injury or death.

CAUTION − Hazards or unsafe practices which

may result in minor personal injury or product or

property damage.

NOTE − Used to highlight suggestions which will

result in enhanced installation, reliability, or

operation.

!

WARNING

Signal Words in Manuals

The signal word CAUTION is used throughout

this manual in the following manner:

!

CAUTION

Signal Words on Product Labeling

Signal words are used in combination with

colors and/or pictures or product labels.

The signal word WARNING is used throughout

this manual in the following manner:

Safety−alert symbol

When you see this symbol on the unit and in

instructions or manuals, be alert to the

potential for personal injury.

TABLE OF CONTENTS

START−UP, ADJUSTMENT, AND SAFETY CHECK 4...........

THERMOSTAT SETUP SWITCH 4...........................

PRIME CONDENSATE TRAP WITH WATER 4.................

PURGE GAS LINES 4......................................

ADJUSTMENTS 5.........................................

ADJUST TEMPERATURE RISE 10............................

ADJUST BLOWER OFF DELAY (HEAT MODE) 11..............

ADJUST COOLING AIRFLOW 11.............................

ADJUST CONTINUOUS FAN AIRFLOW 11....................

ADJUST THERMOSTAT HEAT ANTICIPATOR 11...............

CHECK SAFETY CONTROLS 12.............................

CHECKLIST 12.............................................

SERVICE AND MAINTENANCE PROCEDURES 13.............

ELECTRICAL CONTROLS AND WIRING 13...................

TROUBLESHOOTING 13....................................

CLEANING AND/OR REPLACING AIR FILTER 15..............

BLOWER MOTOR AND WHEEL MAINTENANCE 15............

CLEANING BURNERS AND FLAME SENSOR 17...............

SERVICING HOT SURFACE IGNITER 18......................

FLUSHING COLLECTOR BOX AND DRAINAGE SYSTEM 18....

CLEANING CONDENSATE DRAIN AND TRAP 19..............

CLEANING HEAT EXCHANGERS 19..........................

SERVICE LABEL 21.........................................

WIRING DIAGRAM 22.......................................

SEQUENCE OF OPERATION 25.............................

PARTS REPLACEMENT INFORMATION GUIDE 29.............

PRODUCT NOMENCLATURE 30.............................

MODELS

(F/G)9MXT0401410A

(F/G)9MXT0601714A

(F/G)9MXT0801716A

(F/G)9MXT0802120A

(F/G)9MXT1002120A

(F/G)9MXT1202422A

Use of the AHRI Certified TM Mark indicates a

manufacturer’s participation in the program.

For verification of certification for individual

products, go to www.ahridirectory.org .